This morning a squeak/tick started happening and got worse on my ride home. Over every movement in the rear end a squeak.

After some investigating it's the bolt from the UCA to the diff.

Wow, that is LOUD. Welcome to polyurethane.

I'm not sure who's UCA that is, but I assume its poly. It

sounds like poly that is bone dry - time to lube it up.

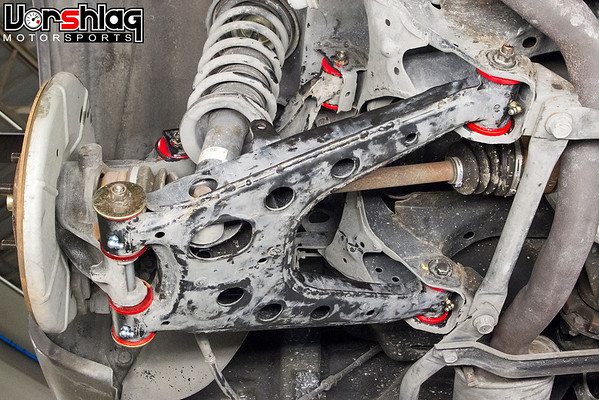

The only way to make poly not squeak over time on the street is to make it a greaseable part. We always add grease zerks when adding poly bushings on a suspension arm. These are some NB Miata arms we just adding poly bushings to in our shop this week.

This rear corner alone has 7 or 8 grease zerks. Each one is drilled through the control arm, through the bushing to the inner bushing sleeve. Then the outer housing is tapped and the grease fitting threaded in. Yes, it takes time to do up front, but from now on when you pump grease in it goes all the way into the inner sleeve, which is where they are usually meant to rotate. If it squeaks you can just squeeze some grease in there with a grease gun in minutes, and the problem is gone for another 3-6 months.

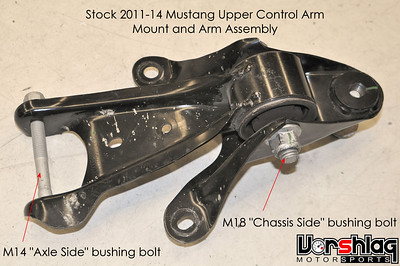

The upper control arms on an S197 are a POOR place for polyurethane, for two reasons. First, the design of the axle housing/bushing mount doesn't lend itself to adding a grease zerk. So to grease it you have to pull it apart and slather it in by hand. Messy and time consuming.

Second reason? There's too much articulation in two opposing axies in these joints, and poly cannot "bend" properly so it tears itself apart. I won't sell a poly UCA for an S197 because of this. Sure, the OEM rubber bushing eats itself over time, but it just starts to crack - quietly. Rubber can also "rotate" more easily in this joint than poly due to the added flex. The right solution? A spherical bushing that can pivot AND rotate, at both the chassis and axle end of the UCA (see above). But they can and will make noise, eventually.

BANG! BANG! BANG! Its just a matter of time on a street car. Or they transmit massive vibrations into the cabin - seen that as well. For a race car it just becomes a regularly serviceable part, and who can hear suspension noise over a race exhaust? Most street guys just let them rattle and bang. I swear 80% of the driving public is stone deaf.

The S197's only real problem that isn't really fixable on a street car.

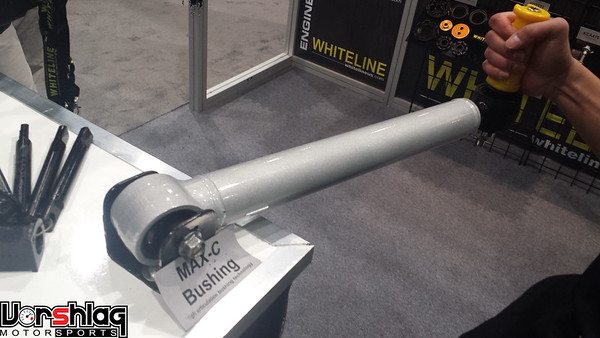

Well... eventually Whiteline will have their Max-C elastomer bushing UCA design released (its in prototype form now). We have requested one and will test it on Jon's S197 when it arrives... hoping its the solution for proper articulation, firmness, and quietness.

Anyway, that's just my two cents. Don't take it as gospel. Sure, we've worked on 400+ Mustangs in the past 7 years, and have seen every variety of brand/material/type of UCA. Somebody will chime in with their "My XXX brand part is perfect"... but again, most of the time people don't even know when something is massively loose or has fallen off their cars, from what we've seen.

I'm not sure who's UCA that is, but I assume its poly. It sounds like poly that is bone dry - time to lube it up.

I'm not sure who's UCA that is, but I assume its poly. It sounds like poly that is bone dry - time to lube it up.