Hey guys new here, my friend recommended this site and well here I am.. I have a 2010 mustang that I haven't driven in almost 6 years....

About the car, I bought the car in late 2011 with 54k miles(YES my dream car) shortly after the car started to develop transmission problems. It started with a faint whine that you could only hear at cold start and would go away after a short drive. At 120K the car developed an intermittent transmission problem, the car wouldn't go in reverse and drive after the car would sit overnight not to mention the whine got louder, so loud that my exhaust was non existent but the whine would go away after a long LONG drive, and lastly both front struts went bad.. I took the car to my local Transmission shop and determined that something "broke" inside and contaminated my whole transmission, they recommended a rebuild for 2.5K, never did it and after that in a way I stopped caring about it, so I started driving the car a bit rough, and never even bothered to address the bad struts, so every bump.... well you guys can imagine..

At 160k(~2015) the whine was so loud that I stopped driving it for a few months and left it at my uncles dairy inside a storage shed, well unfortunately I'm guessing mice got in the engine bay and chewed a few wires since it got the CEL with almost a million codes, even though I was never able to find a nest, so in 2016 the car was finally stored and in non op since I wasn't able to pass my emission test(CA).

Now due to recent events (totaled my main car) I've brought the car back home and started fixing a few issues starting with the bad struts.. Ive replaced the front struts and rear shocks with KONI and installed Eibach Sportline Lowering Springs BUT I'm still don't know what to do, and yeah driving the car for a long time with bad struts damaged something else since it feels like something is loose even with the new struts/springs when you go over bumps or a drive way, and yeah everything is tight... ATM the car has 165K miles, so before I dump more money into it, I have done the following:

*Compression test (COLD)

1-6 Cylinders are EXACTLY at 170PSI (Tested twice)

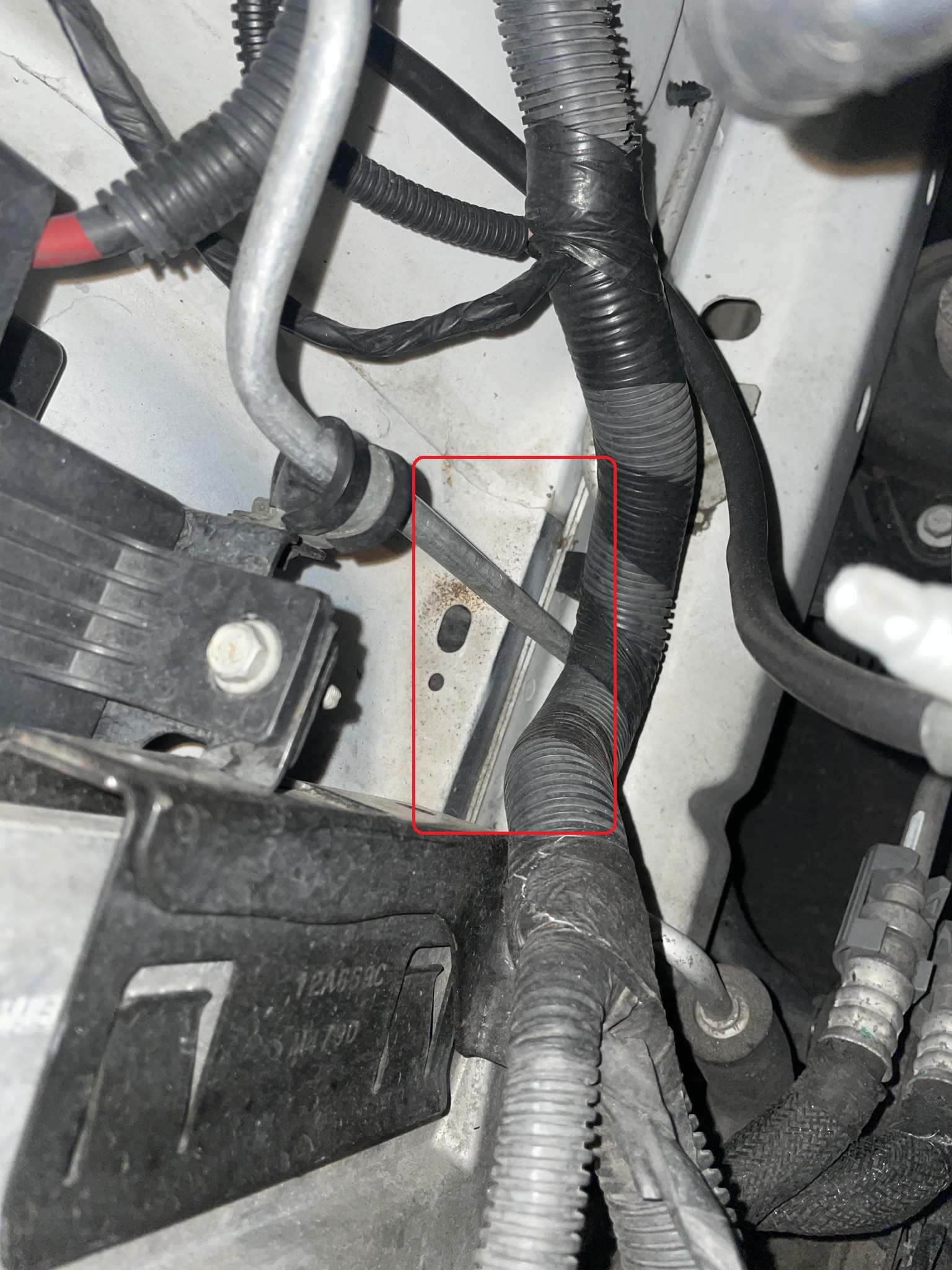

*Took the car to my local Ford Dealership to diagnose the CEL... came back with mixed answers, from a new wiring harness to a new computer, to a new fuse box.. meaning they AREN'T SURE, although for some reason my wiring harness conduit falls apart extremely easy.. all of it does, its almost gone..

*Lastly Ive inspected the transmission oil and filter, the oil is dark.. looks like used engine oil, pan and filter looked somewhat ok.

Finally a few things I just discovered... ughh..

*Car was in a small wreck.. they did one hell of a job fixing it, it even fooled me back in 2011.

That panel was replaced(online pic) question is WHY? there is no frame damage, and the front end is original with no sings of the radiator support being replaced or fixed, the original weld spots are still visible..

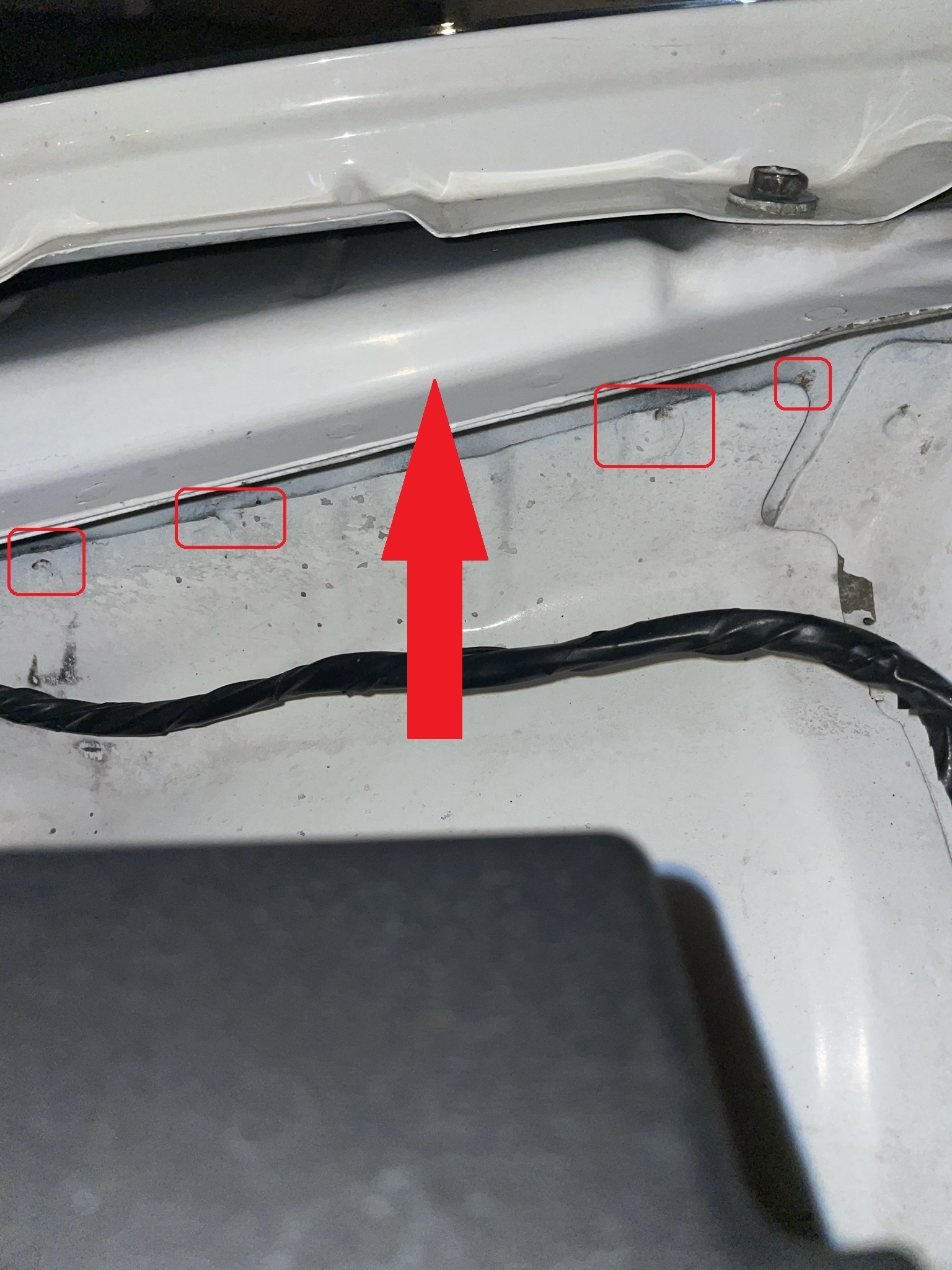

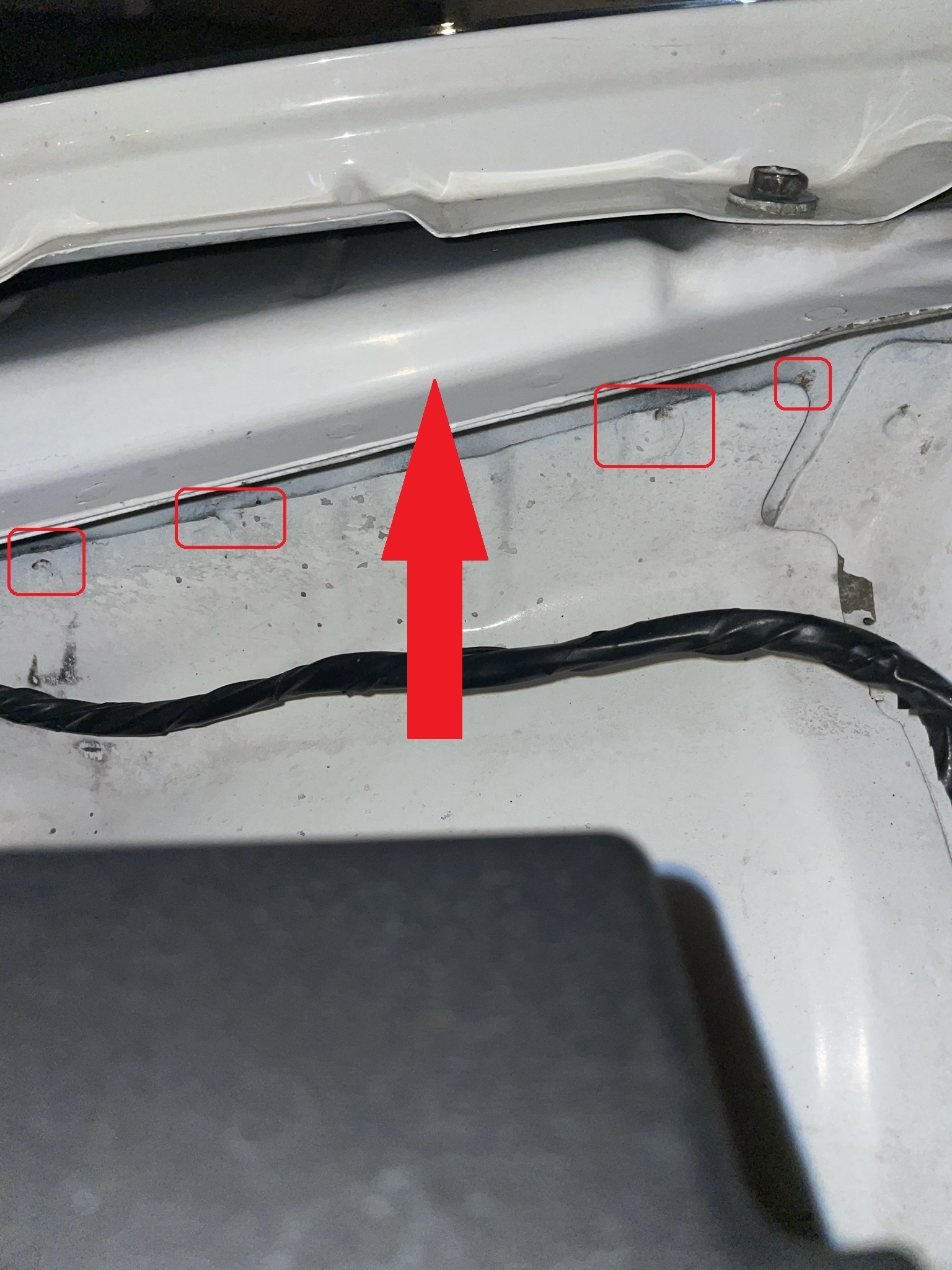

Welding spots, NOT factory. Red arrow not damaged, fender was removed and I didn't find any visible damage or repair attempts.

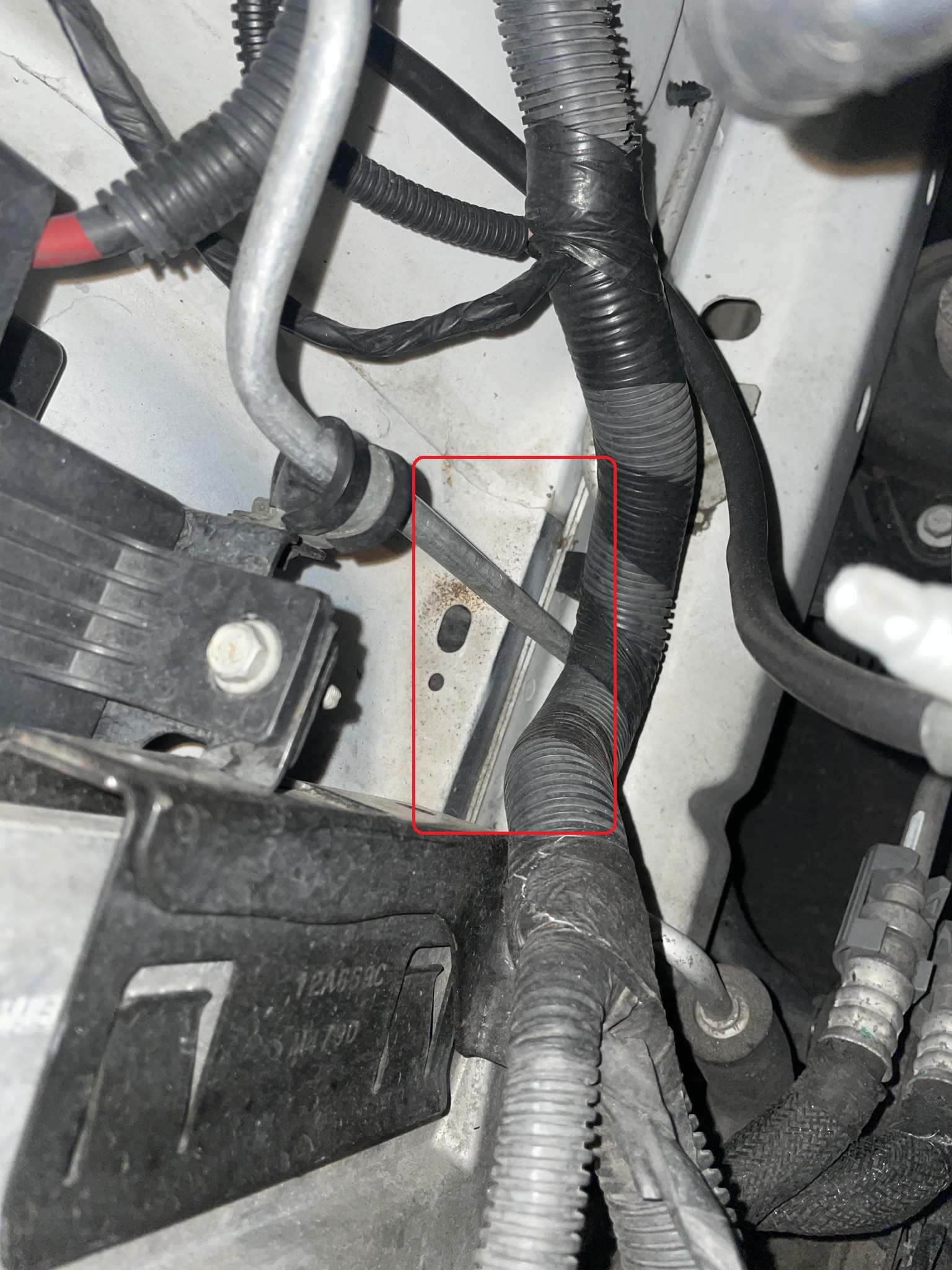

Primer clearly visible.. ^

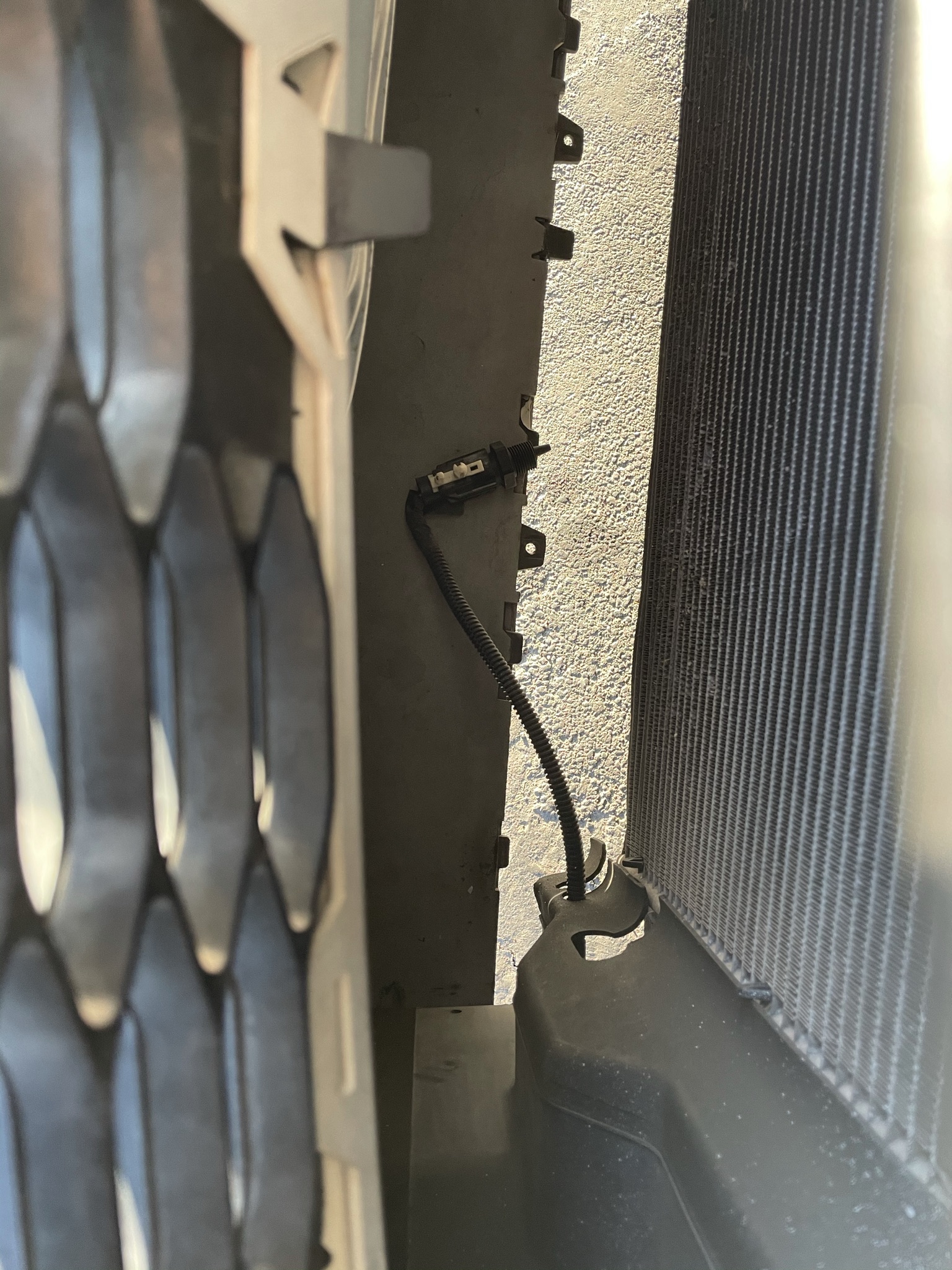

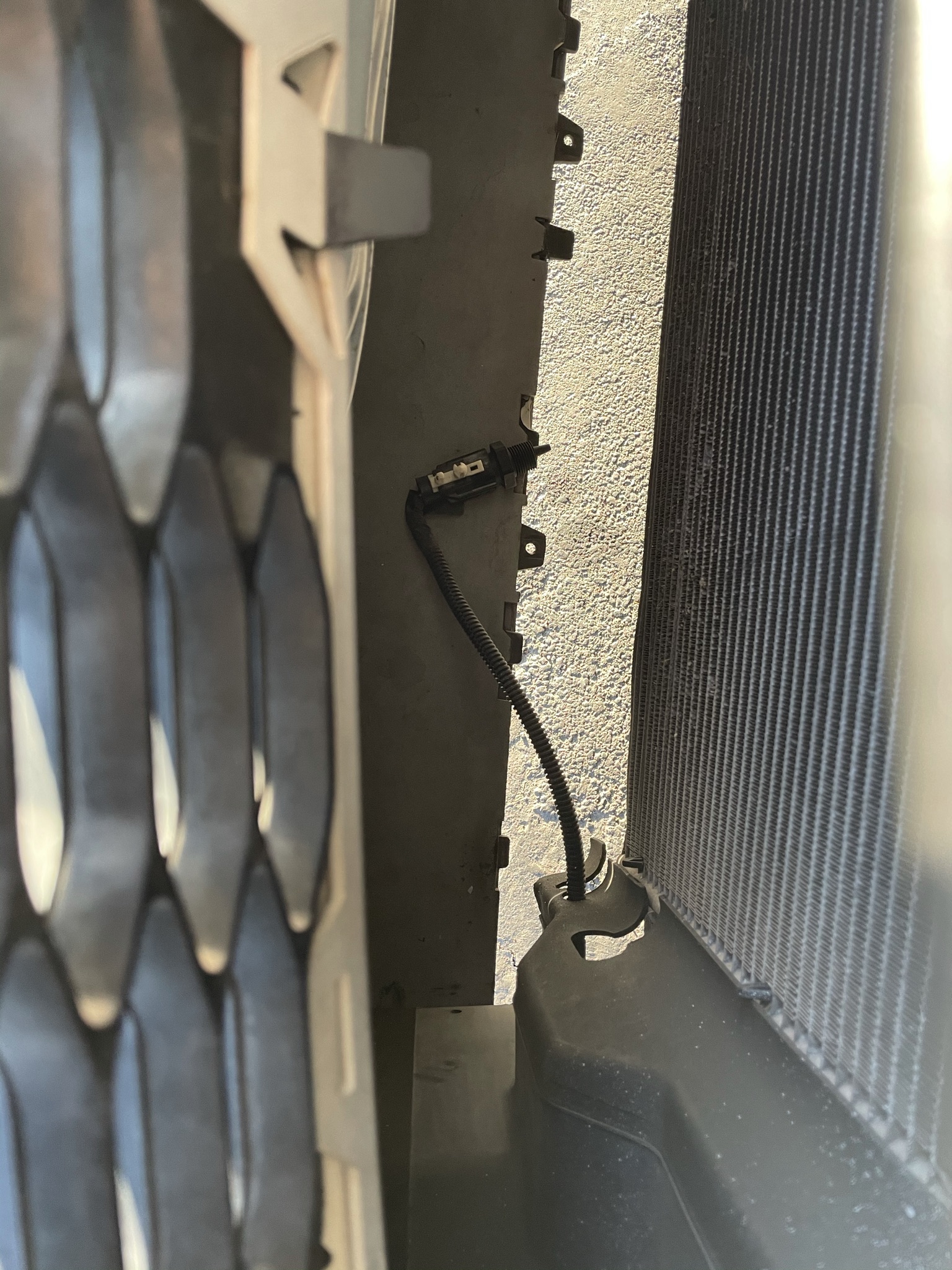

Wile Removing the front bumper to inspect if any other repairs were done, I found this... the crash sensor just laying there with obvious wear, at one point it was dragging, question is where exactly does it go? I looked every where when the bumper was off and I cant seem to find its location..

That wasn't there last time I saw the car.. it doesn't seem like rust, it just seems like its another classic case of the amazing Ford paint quality..

Finally the transmission whine, and yeah that's an 05-09 steering wheel..

At this point I'm not sure what to do, I still love the car, I even purchased a set of BOSS 352 rims(still in box) a wile back for it... aside from the issues, the car itself is in great shape with NO dents anywhere, and the interior is flawless. Ford did offered me a new Mustang, but.... I'm not a fan of the modern S550's... thoughts, opinions?

About the car, I bought the car in late 2011 with 54k miles(YES my dream car) shortly after the car started to develop transmission problems. It started with a faint whine that you could only hear at cold start and would go away after a short drive. At 120K the car developed an intermittent transmission problem, the car wouldn't go in reverse and drive after the car would sit overnight not to mention the whine got louder, so loud that my exhaust was non existent but the whine would go away after a long LONG drive, and lastly both front struts went bad.. I took the car to my local Transmission shop and determined that something "broke" inside and contaminated my whole transmission, they recommended a rebuild for 2.5K, never did it and after that in a way I stopped caring about it, so I started driving the car a bit rough, and never even bothered to address the bad struts, so every bump.... well you guys can imagine..

At 160k(~2015) the whine was so loud that I stopped driving it for a few months and left it at my uncles dairy inside a storage shed, well unfortunately I'm guessing mice got in the engine bay and chewed a few wires since it got the CEL with almost a million codes, even though I was never able to find a nest, so in 2016 the car was finally stored and in non op since I wasn't able to pass my emission test(CA).

Now due to recent events (totaled my main car) I've brought the car back home and started fixing a few issues starting with the bad struts.. Ive replaced the front struts and rear shocks with KONI and installed Eibach Sportline Lowering Springs BUT I'm still don't know what to do, and yeah driving the car for a long time with bad struts damaged something else since it feels like something is loose even with the new struts/springs when you go over bumps or a drive way, and yeah everything is tight... ATM the car has 165K miles, so before I dump more money into it, I have done the following:

*Compression test (COLD)

1-6 Cylinders are EXACTLY at 170PSI (Tested twice)

*Took the car to my local Ford Dealership to diagnose the CEL... came back with mixed answers, from a new wiring harness to a new computer, to a new fuse box.. meaning they AREN'T SURE, although for some reason my wiring harness conduit falls apart extremely easy.. all of it does, its almost gone..

*Lastly Ive inspected the transmission oil and filter, the oil is dark.. looks like used engine oil, pan and filter looked somewhat ok.

Finally a few things I just discovered... ughh..

*Car was in a small wreck.. they did one hell of a job fixing it, it even fooled me back in 2011.

That panel was replaced(online pic) question is WHY? there is no frame damage, and the front end is original with no sings of the radiator support being replaced or fixed, the original weld spots are still visible..

Welding spots, NOT factory. Red arrow not damaged, fender was removed and I didn't find any visible damage or repair attempts.

Primer clearly visible.. ^

Wile Removing the front bumper to inspect if any other repairs were done, I found this... the crash sensor just laying there with obvious wear, at one point it was dragging, question is where exactly does it go? I looked every where when the bumper was off and I cant seem to find its location..

That wasn't there last time I saw the car.. it doesn't seem like rust, it just seems like its another classic case of the amazing Ford paint quality..

At this point I'm not sure what to do, I still love the car, I even purchased a set of BOSS 352 rims(still in box) a wile back for it... aside from the issues, the car itself is in great shape with NO dents anywhere, and the interior is flawless. Ford did offered me a new Mustang, but.... I'm not a fan of the modern S550's... thoughts, opinions?

, the best part is that I haven't lost any gears anymore.. so far I've successfully put over 200 miles and no issues, will repeat the process one last time on the next oil change, but of course this doesn't mean the transmission is 100% healthy..

, the best part is that I haven't lost any gears anymore.. so far I've successfully put over 200 miles and no issues, will repeat the process one last time on the next oil change, but of course this doesn't mean the transmission is 100% healthy.. , I checked the grounds and they were bad, I cleaned them to no avail I still get the CEL. Something else that I've noticed is that my temperature reading on my stereo is ALWAYS stuck at 50 degrees, and sometimes (NOT all the time) when I start my A/C, the clutch "tweaks out" it starts then stops randomly causing the ac to not work properly.. and when that happens I usually get the CEL with all the random codes..

, I checked the grounds and they were bad, I cleaned them to no avail I still get the CEL. Something else that I've noticed is that my temperature reading on my stereo is ALWAYS stuck at 50 degrees, and sometimes (NOT all the time) when I start my A/C, the clutch "tweaks out" it starts then stops randomly causing the ac to not work properly.. and when that happens I usually get the CEL with all the random codes..