When I went to slow down into 10A after the looooong back straight during an extra long stint - the pedal went to the floor. And didn't come back. While doing about 155 mph.

It was a hard hit, and I think most of my damage (compression fracture to vertebrae T-11 and broken rip at T-12) happened where the picture shows, coming OUT of the gravel trap. It was about a foot high ridge of dirt where they cut into the earth to dig out the hole for the gravel pit.

I didn't black out so I remember most of the hit, but I couldn't breathe for about 90 seconds (knocked the wind out of me) and I knew I had broken something in my back. I managed to avoid the two cars ahead of me, all of the walls and the bridge itself, steered it into Pit In, and coasted right in front of the medical building. I then popped the straps and rolled out of the car, where the medics were on me in seconds.

I stupidly refused a hospital visit at the scene and waited until this past Monday to get X-rays, and saw the broken bones. I just got back from another doc visit (pain meds FTW!) and go in for an MRI next week. Oh well, live and learn.

27 years of doing this stuff, dozens of offs at all sorts of speeds, but this is the first time I got hurt. Car doesn't even look that bad.

---

Yes, we are reevaluating all of my and the car's safety gear, and I will be adding a HANs device before I take another lap in anger. Which would help for a different kind of wreck than this, though.

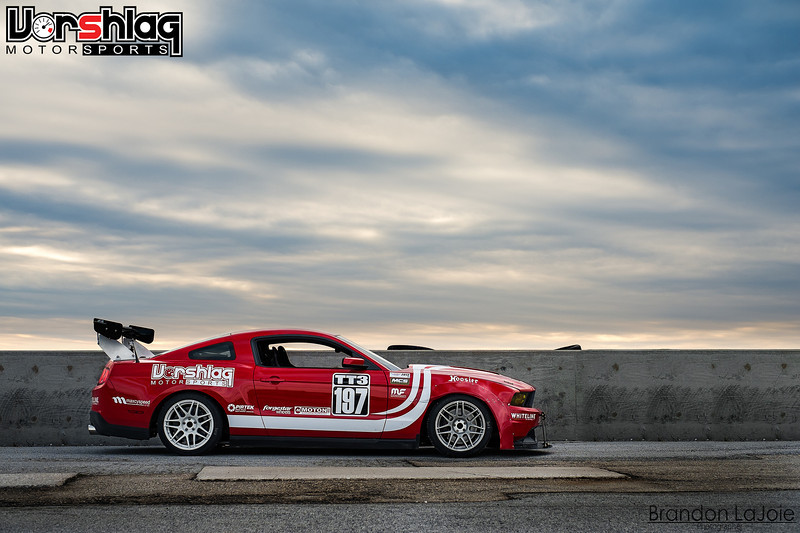

This impact at Road Atlanta was almost entirely VERTICAL in nature. This shunt didn't trigger any of the airbags (which are functional) and would have popped with any forward-type impact, so a HANs device would have had no affect on my outcome. Neither would a full roll cage, in this instance. This car does not race wheel-to-wheel and is still a STREET DRIVEN and STREET LEGAL car, so this one won't ever get a "full cage" while we race it for the rest of 2014. I'm not keen on driving around on the street with steel tubing next to my head, even with SFI padding that is a recipe for disaster. It is a rare car/driver combo that can have a fully functional cage and still be 100% safe for street driving with a non-helmeted driver.

Look guys, I appreciate the advice, and I've heard it all this week from every expert on the internet, via Facebook. Again: a full roll cage and a HANs would have had ZERO effect in this somewhat unusual impact vector (Z-axis) shunt. We have only a handful of events left in this car this year and then it will likely be de-modded back into a 100% street car/daily driver while we prep and develop the 2015 Mustang to race for the 2015 season in TT2 or TT3.

But... yes, we are going kind of fast at some tracks for an un-caged car, I know (although it does have a robust 4-point roll bar with diagnoal, an FIA halo racing seat, Schroth 6-point harnesses, etc). And the 2015 Mustang might be faster than this car (we should know weights and power numbers next week, by 5/20), and if so I've already negotiated with Amy to potentially make the S550 Mustang to have a more gutted/caged/race car type of safety gear prep. But to do that I have to make this red 2011 GT into a real street car again, and revert it back into her "pretty pony" by removing the splitter, wing, super-loud exhaust, RR2 dampers and some of the more racey bits.

Will the 2015 "S550" Mustang GT be significantly more powerful and/or lighter than the S197??

We shall soon see. It all kind of depends on how well Ford designed the 2015 GT, and/or if the "GT350/Voodoo" car comes out in a short time frame. If the 500+ hp Voodoo Mustang engine is real, significantly faster, not boosted, and comes in a car available for under $75K within the calendar year (aka: a Z/28 fighter!)... the 2015 GT we already have on order will be used as a temporary development mule and will get "bolt-on only" mods. Then we will switch to the Voodoo car and go hod wild... caged, flared, carbon ceramic brakes, and faster.

More soon,

It was a hard hit, and I think most of my damage (compression fracture to vertebrae T-11 and broken rip at T-12) happened where the picture shows, coming OUT of the gravel trap. It was about a foot high ridge of dirt where they cut into the earth to dig out the hole for the gravel pit.

I didn't black out so I remember most of the hit, but I couldn't breathe for about 90 seconds (knocked the wind out of me) and I knew I had broken something in my back. I managed to avoid the two cars ahead of me, all of the walls and the bridge itself, steered it into Pit In, and coasted right in front of the medical building. I then popped the straps and rolled out of the car, where the medics were on me in seconds.

I stupidly refused a hospital visit at the scene and waited until this past Monday to get X-rays, and saw the broken bones. I just got back from another doc visit (pain meds FTW!) and go in for an MRI next week. Oh well, live and learn.

27 years of doing this stuff, dozens of offs at all sorts of speeds, but this is the first time I got hurt. Car doesn't even look that bad.

---

Yes, we are reevaluating all of my and the car's safety gear, and I will be adding a HANs device before I take another lap in anger. Which would help for a different kind of wreck than this, though.

This impact at Road Atlanta was almost entirely VERTICAL in nature. This shunt didn't trigger any of the airbags (which are functional) and would have popped with any forward-type impact, so a HANs device would have had no affect on my outcome. Neither would a full roll cage, in this instance. This car does not race wheel-to-wheel and is still a STREET DRIVEN and STREET LEGAL car, so this one won't ever get a "full cage" while we race it for the rest of 2014. I'm not keen on driving around on the street with steel tubing next to my head, even with SFI padding that is a recipe for disaster. It is a rare car/driver combo that can have a fully functional cage and still be 100% safe for street driving with a non-helmeted driver.

Look guys, I appreciate the advice, and I've heard it all this week from every expert on the internet, via Facebook. Again: a full roll cage and a HANs would have had ZERO effect in this somewhat unusual impact vector (Z-axis) shunt. We have only a handful of events left in this car this year and then it will likely be de-modded back into a 100% street car/daily driver while we prep and develop the 2015 Mustang to race for the 2015 season in TT2 or TT3.

But... yes, we are going kind of fast at some tracks for an un-caged car, I know (although it does have a robust 4-point roll bar with diagnoal, an FIA halo racing seat, Schroth 6-point harnesses, etc). And the 2015 Mustang might be faster than this car (we should know weights and power numbers next week, by 5/20), and if so I've already negotiated with Amy to potentially make the S550 Mustang to have a more gutted/caged/race car type of safety gear prep. But to do that I have to make this red 2011 GT into a real street car again, and revert it back into her "pretty pony" by removing the splitter, wing, super-loud exhaust, RR2 dampers and some of the more racey bits.

Will the 2015 "S550" Mustang GT be significantly more powerful and/or lighter than the S197??

We shall soon see. It all kind of depends on how well Ford designed the 2015 GT, and/or if the "GT350/Voodoo" car comes out in a short time frame. If the 500+ hp Voodoo Mustang engine is real, significantly faster, not boosted, and comes in a car available for under $75K within the calendar year (aka: a Z/28 fighter!)... the 2015 GT we already have on order will be used as a temporary development mule and will get "bolt-on only" mods. Then we will switch to the Voodoo car and go hod wild... caged, flared, carbon ceramic brakes, and faster.

More soon,

Last edited:

Wearing a back brace helps a lot, but I still cannot sleep more more than a couple of hours a night. Oh well, it will heal...

Wearing a back brace helps a lot, but I still cannot sleep more more than a couple of hours a night. Oh well, it will heal...