Knock-back is NOT common, at least on HPDE level S197s. When you get to TT or in the race groups, it becomes more common, but it's still not something that you'll see with any regularity unless your hubs are toast or you're REALLY whacking the berms. Trust me, this is a RARE thing to experience. In my years of TT and racing, so far I've had it happen exactly once, and that was due to failing wheel bearings, NOT berm-hopping (which I do) or high-load cornering (which I also do). It STILL makes sense just to give the brakes a left-foot tap before getting to the big braking zones, though.

Good tips and data from Dave, as usual. I was wondering if this was knock-back that caused the TOTAL loss of pedal, as I had a firm pedal braking into Turn 7 right before the L-O-N-G back straight. Pro racer Jason Saini suggested the same cause (knockback), and the same cure: a little tap of the brake pedal with the left foot on long straights just to re-seat the pads. Its a trick I'm going to employ in the future, for sure.

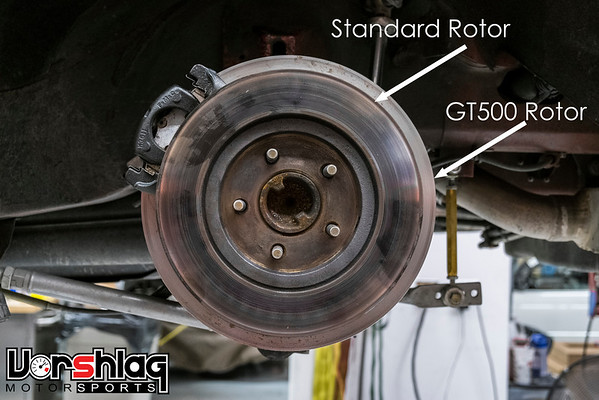

But as Jason mentioned the brake pedal was still MUSHY AS ALL HELL when we drove the car a week after the accident. The guys here flushed out all of the Motul 600 and replaced it with 660, and the pedal is perfect again. And yes, the front pads had less than 1/4 of the material thickness left (see picture below!), and the rears were just as bad.

That didn't help matters, of course. And while I have used SRF on some customers' cars, its not the right fluid for me. I'm a Motul dealer, and I try to race what we sell, and I kind of like a

little hygroscopic aspect to the fluid. The DOT5 silicone stuff has never really been my favorite brake fluid.

The titanium shims between calipers and pads have been suggested by many, and I've seen all sorts of tricks like this over the past 27 years of doing track events... but none of it works all that well, in my opinion. It might barely slow down the heat transfer but once that heat passes into the calipers they'd act like an insulator. Just like the phenolic upper intake manifold spacers people used to use on 2-piece aluminum intake ... it worked great for a very short period (drag racers), but then it became an insulator, trapping heat where you didn't want it. No, I've just got to go out on track at these brake intensive tracks full thickness, and leave those 1/2 and 1/4 thickness pads for "less critical uses" like autocross or whatnot.

And while I did jump up pentalab's ass for his silly observations (he has been doing this all over this forum, and I'm not the only one noticing) I

do appreciate all of the tips, suggestions, tricks and advice from the more experienced folks. And anyone is free to ask questions of us here anytime, in this thread or elsewhere.

That's why we're here. I don't hold anything back, and this accident was

totally avoidable. So please, learn from my mistakes!

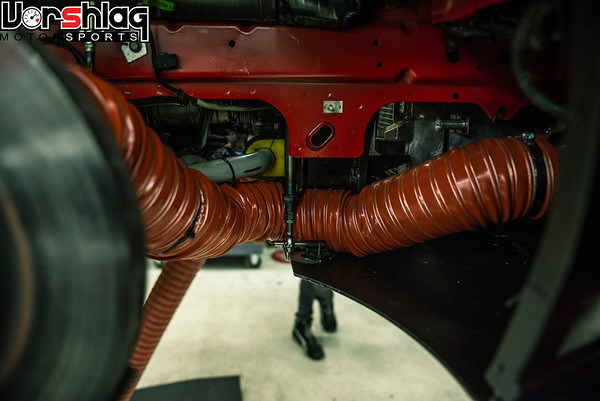

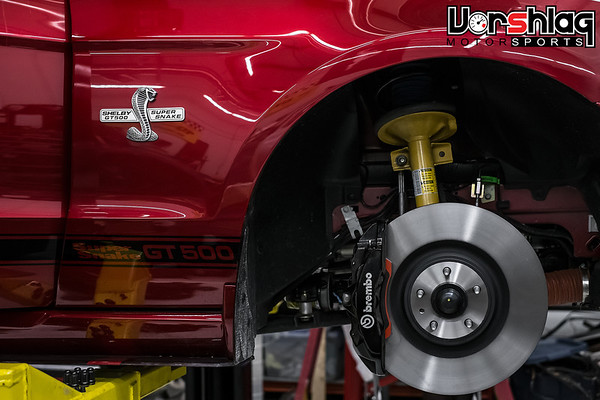

We're testing the 4" brake ducts (fix #1, see below) tomorrow at a brake intensive track - Eagles canyon Raceway. Amy is driving, as my broken bones are still healing for at least 4 more weeks before I can get back in the car. I'm hoping by NASA @ Hallett in late June that I'll be able to drive, to defend both of my track records there (TT3 going CW and CCW)! We'll see. I'm going NUTS not being able to race... or go to the gym, or lift more than about 5 pounds, or lay down flat or bend over without serious pain.

GRR!

I'm also going to be sticking temp strips on a number of other Mustangs' Brembo calipers tomorrow at ECR, to check their temperatures vs their pad material vs their track times. Could be some good data to share!

Mustang is all fixed now: it has a new bumper cover, one new plastic side skirt, brand new XP20 pads and 660 fluid, and the bigger brake ducting. It is all loaded up and ready for track abuse once again (we will be at ECR at 7 am tomorrow). The splitter took almost no damage, and with a new bumper cover and some mounts + some patches to the flares it is all good to go.

Cheers!