boostedtrauma

Junior Member

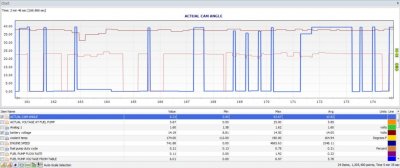

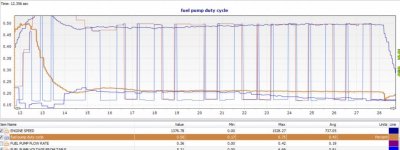

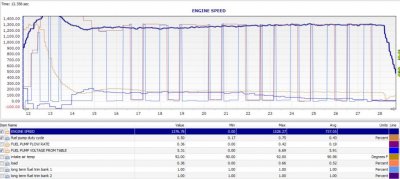

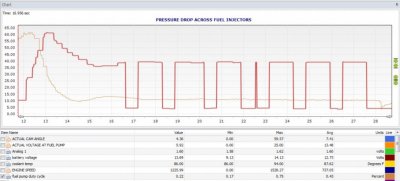

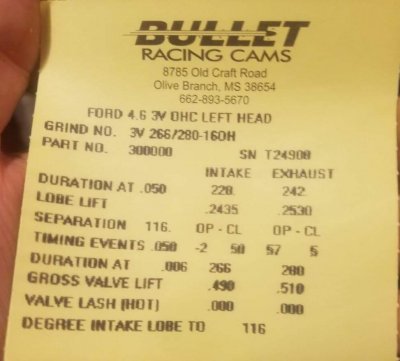

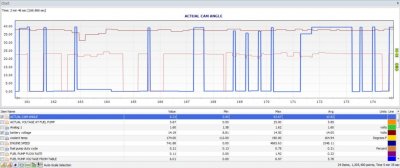

Following the Stroker/6060/TVS swap, I am having an issue with fuel rail pressure pinging between 0 and 39psi and cam position pinging between 0 degrees and 40 degrees.

The wiring harness is unchanged from before the engine swap. Grounds over the passenger side headlight, passenger engine mount bracket, and driver side cylinder head to firewall have been inspected (hooked up, free of corrosion or visual imperfection).

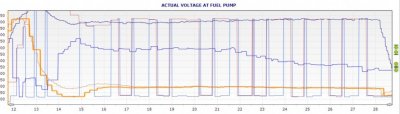

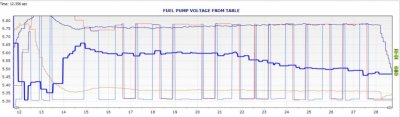

I put two new DW340 pumps in my GT500 dual pump assembly that I have ran since 2017 without issue. I am considering swapping the pumps back out to stock GT500 pumps to rule out a failing pump.

So far, I have replaced the battery, alternator, and FRPS with no changes.

I have probed the cam position sensors on the new engine and known good ones on the engine I pulled out. All read about 355 ohms, so I am assuming the CPS sensors themselves are good.

I probed the GRY/RED signal return wire from each sensor (FRPS, CPS1, CPS2) to Fuse 58 using sewing needles and a multimeter and got 6.70 kohm. This value seems high, but is consistent for each sensor. This leads me to thinking I may have a bad connector/splice point.

Looking into the wiring diagrams, I see reference to a splice point 102 where all of this comes together prior to the connectors. Do any of you know roughly where this point is? I wrapped my wiring harness with ELEVEN rolls of 3M electrical tape while the engine was out, so cutting into can hopefully be kept to a minimum.

If not wiring, could a bad DW340 pump be causing this, as in the fuel pressure pinging is actual and the cams are "coughing" as a result? It doesn't have the diesel clack I've always associated with failing 3v phasers, and no codes, granted it has about 5 minutes of run time and one mile since first start.

The wiring harness is unchanged from before the engine swap. Grounds over the passenger side headlight, passenger engine mount bracket, and driver side cylinder head to firewall have been inspected (hooked up, free of corrosion or visual imperfection).

I put two new DW340 pumps in my GT500 dual pump assembly that I have ran since 2017 without issue. I am considering swapping the pumps back out to stock GT500 pumps to rule out a failing pump.

So far, I have replaced the battery, alternator, and FRPS with no changes.

I have probed the cam position sensors on the new engine and known good ones on the engine I pulled out. All read about 355 ohms, so I am assuming the CPS sensors themselves are good.

I probed the GRY/RED signal return wire from each sensor (FRPS, CPS1, CPS2) to Fuse 58 using sewing needles and a multimeter and got 6.70 kohm. This value seems high, but is consistent for each sensor. This leads me to thinking I may have a bad connector/splice point.

Looking into the wiring diagrams, I see reference to a splice point 102 where all of this comes together prior to the connectors. Do any of you know roughly where this point is? I wrapped my wiring harness with ELEVEN rolls of 3M electrical tape while the engine was out, so cutting into can hopefully be kept to a minimum.

If not wiring, could a bad DW340 pump be causing this, as in the fuel pressure pinging is actual and the cams are "coughing" as a result? It doesn't have the diesel clack I've always associated with failing 3v phasers, and no codes, granted it has about 5 minutes of run time and one mile since first start.