You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Knock sensor question

- Thread starter Laga

- Start date

GlassTop09

Senior Member

Here ya go Laga:Is there a right and left side knock sensor? Would it make a difference if they are switched?

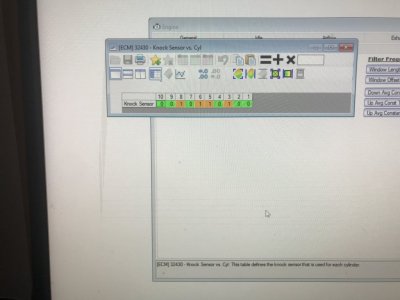

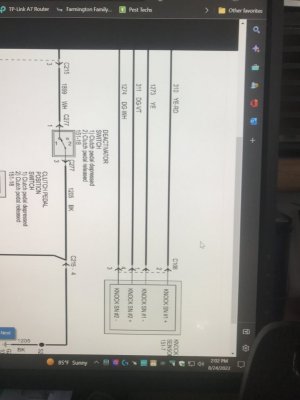

These pictures are 1. from my tune file that shows the knock sensor to cyl assignment. This is the stock OEM mapping & 2. from the FWM wiring schematic showing the wire color designation to designate knock sensor #1 from #2.

I assume that knock sensor #1 correlates to knock sensor #0 in tune & knock sensor #2 matches knock sensor #1 in tune......knock sensor #0 is B1, knock sensor #1 is B2.

The assignment seems to follow the engine firing order in a staggered pattern except for #5 & #6 cyl which are the only 2 adjacent firing cyl's that are using the same knock sensor (#1 for B2).

Hope this helps.

Here is my problem. I recently had the engine rebuilt. I also had someone else pull and reinstall engine because I can no longer do that heavy work anymore. Lito FINALLY got back to me and asked if there were any loose exhaust parts because there is a TON of detonation in the new engine despite running E85 at 80% ethanol. He said this doesn't make sense. He is working on tune now. There are no loose parts. I can see with a borescope that the knock sensors are in place and bolted down. If they were swapped from their original location, would this show up as excessive detonation?

GlassTop09

Senior Member

Yes, if these knock sensors are switched across cyl banks from their original mounting, this can throw off the per cylinder knock threshold sensitivity tuning settings that were set in the tune based on the original cyl-to-sensor assignments as set in the tune (please note that these assignments also follow the cyl pairing to crank journal....ie, cyl #1 & #5 on the 1st pair, cyl #2 & #6 on the 2nd pair, etc in addition to firing order) making some cylinders more sensitive to knock than prior, some less.If they were swapped from their original location, would this show up as excessive detonation?

This is why I provided the tune cyl-to-sensor assignment along w\ the wiring diagram pictures showing the harness side connector wire colors to ID them as there are no other markings on the actual sensors that do......at least I didn't see any on mine when I had my IM off several times.

These knock sensors that fit our MY S197's use a siamese-type connector (both sensors use the same M-F connector housing\socket) thus I can easily see these getting switched across banks unless this is known prior & are labeled to facilitate them getting installed back on original bank mountings to prevent this from happening.

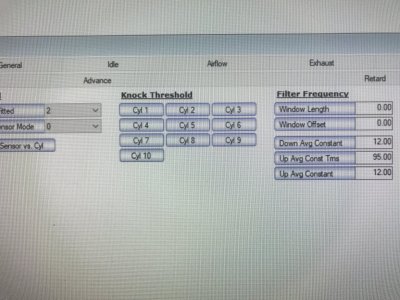

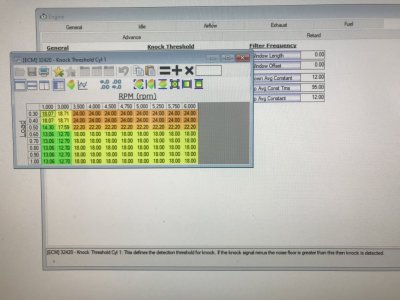

PS--I provided below a picture of the cyl knock threshold sensitivity tuning maps to finish showing this correlation thus give flesh to what I typed above.

Last edited:

Thank you for the information.

May I ask one more question since I haven’t heard from Lito in two days?

Will he be able to adjust for the new sensor location, if this is the cause of the detonation, or will the KS’s need to be put back in their original spots?

May I ask one more question since I haven’t heard from Lito in two days?

Will he be able to adjust for the new sensor location, if this is the cause of the detonation, or will the KS’s need to be put back in their original spots?

GlassTop09

Senior Member

Sorry, just got back from road tripping my car..............Thank you for the information.

May I ask one more question since I haven’t heard from Lito in two days?

Will he be able to adjust for the new sensor location, if this is the cause of the detonation, or will the KS’s need to be put back in their original spots?

Yes, he can readjust all this. I'm sure Lito has some vetted knock sensor data recorded from a similar config to yours using E85 around the 80% content level to use for a baseline to determine where your situation is, then adjust from there......but it would also be helpful if you could actually verify that these KS's actually got swapped then relay this info to him before going any further on your end. It would also be better to put them back to their correct mounting IF they are verified to be cross mounted, but that would require removing the Edelbrock blower\manifold which I know you really don't want to do that if you don't have to. TBH, if you have to remove the blower\manifold I'd suggest to replace them w\ a new set of KS's then make sure they're mounted according to the wiring diagram so this is done 1 time.

Since you have a borescope in hand, I'd suggest to look at the KS connector on harness side to ID the 2 yellow wires (KS #1) then move to KS side of connector to ID the 1 sensor lead that lines up w\ the 2 yellow wires then trace it to see if it's KS head actually is mounted on B2 instead of B1.

You might find that the shop didn't cross mount them after all & they may just be overly sensitive to your new rotating assembly in the block.........

Lito will get it all figured out as I'm very sure he's been here, done that several times in the past, thus this isn't new to him.

Last edited:

I talked to the shop earlier and he did not mark the KSs as he was not aware that it made a difference. I will further investigate with the scope and see what I can find.

Yes, I would prefer not to pull the Edelbrock unit, but it really isn’t that big of a job. I’ll just need help lifting it off.

That’s what son-in-laws are for. Still waiting for a reply from Lito. I emailed him today about the possibility of the switch so at least he knows.

Again, I appreciate your help. I’ll post what happens.

Yes, I would prefer not to pull the Edelbrock unit, but it really isn’t that big of a job. I’ll just need help lifting it off.

That’s what son-in-laws are for. Still waiting for a reply from Lito. I emailed him today about the possibility of the switch so at least he knows.

Again, I appreciate your help. I’ll post what happens.

GlassTop09

Senior Member

From looking at several stock tune's per cyl KS threshold mapping data, if all this was left stock then it looks like the Ford engineers initially tuned all this w\ the advent of these getting swapped across banks in mind thus it wouldn't make much of a difference (most likely why all stock tunes are set to apply per cyl KS spark advance\retard activity globally.....these 05-10 SO PCM's can be set up to apply per cyl KS spark advance\retard activity on a per cyl basis instead of just globally like a 2V, which explains the per cyl KS setups in the tune files & the advent of the 2nd KS to isolate 1 bank from the other 1 as noted). I found my tune file still set up to do this globally.......have changed it to apply this per cyl now......just like a Coyote.I talked to the shop earlier and he did not mark the KSs as he was not aware that it made a difference.

This becomes more of an issue once the KS cyl threshold maps have been "retuned" from the stock settings or have been set to apply KS spark retard\advance activity on a per cyl basis essentially ensuring a "lock" to the cyl-to-sensor assignment being used in the tune, so it is a good practice to always mark their mounting position before removal as well as ID the KS lead to the harness side KS wire colors to ensure that they get mounted back correctly to avoid any interference w\ the in-tune KS settings\setup.

Last edited:

Ok, I waited 3days and this was the response I got,

“It doesn't make much sense because they are pegged, if they've reached an stabilizing value, then yes, but pegged usually means that the noise is unrelated and no matter how it removes timing, is still there.”

I asked if they should be replaced. I hope it does take another 3 days for a reply.

Anybody have any ideas other than replacement?

The car runs great. No symptoms of detonation and no CEL.

“It doesn't make much sense because they are pegged, if they've reached an stabilizing value, then yes, but pegged usually means that the noise is unrelated and no matter how it removes timing, is still there.”

I asked if they should be replaced. I hope it does take another 3 days for a reply.

Anybody have any ideas other than replacement?

The car runs great. No symptoms of detonation and no CEL.

GlassTop09

Senior Member

Now that info helps.Ok, I waited 3days and this was the response I got,

“It doesn't make much sense because they are pegged, if they've reached an stabilizing value, then yes, but pegged usually means that the noise is unrelated and no matter how it removes timing, is still there.”

I asked if they should be replaced. I hope it does take another 3 days for a reply.

Anybody have any ideas other than replacement?

The car runs great. No symptoms of detonation and no CEL.

These KS's create their own 0-1v voltage off any engine acoustics generated (cam followers, injectors, chains, pistons, rod journals, external components that are physically attached to engine heads, ie--exhaust up to engine detonation......the KS threshold tuning is to remove\cancel all the "normal" engine acoustics so the only acoustic to drive full KS voltage is detonation) so no bias voltage is generated from the PCM so 1 or both KS mics is "falsely generating" full voltage. Only 2 items can create this.........a short in the KS wiring harness between the KS's & PCM or they've gone bad. 1 particular issue that can cause a KS mic to fail is it getting overtightened (these have a TQ spec of 20 Nm or 15 ft-lbs), otherwise they've just gone bad so outside of the harness wiring going bad they'll need to be replaced.

If you have Forscan you can actually check this yourself using Forscan's dashboard (graph). In setup just choose the #1 & #2 KS PIDs & Forscan will show the running KS signals generation so you can see this yourself.

Midlife Crises

Senior Member

If you already have an SCT tuner you can datalog the knock sensors. I have charted them with an X4 and the live link software.

I’ve done that. Lito said the KSs are maxed out, which means the noise is not from detonation. He can’t do anything. I’ve checked the exhaust for loose parts. Tomorrow I will check the front of the engine. Then maybe check the KSs themselves, but that means removing the SC.If you already have an SCT tuner you can datalog the knock sensors. I have charted them with an X4 and the live link software.

redfirepearlgt

forum member

- Joined

- Mar 19, 2011

- Posts

- 2,497

- Reaction score

- 263

great thread here. Love knowing more about the in depth Theory of Operation. I was looking at the schematics of the 2005 Ford tech manual I have and on pg 24-5 it shows the wiring of the knock sensors. It looks like you could check these sensors at the PCM connector with power off. I would assume if they are pegged this would indicate a short across the sensors. The PCM apparently applies the voltage source and ground via connector C175e. Pins 30,31 and pins 48,49 go straight to the KS's.

Assuming - and this is a scary word that the wiring color code is the same (the pin out should be) from 05-09 do a resistance check across the pins as follows.

pin 30 - Dark Green /White stripe

pin 31 - Dark Green / Violet stripe

Pin 48 - Yellow (solid)

Pin 49 - Yellow /Red stripe

This check does not isolate the sensors as the sensors as the problem. It would only confirm an issue with the sensors or wiring prior to yanking 100# of supercharger and intercooler off the engine before knowing if you wish to do any diagnostics beforehand.

As with any resistance check you will need a reliable multimeter. Also assure power is removed from the car. I suggest even disconnecting the battery + as well. You will need to disconnect C175e from the PCM to isolate the circuit from PCM internal resistance.

Last: On the 2015-17 Roush and VMP setups it was important to change the wiring on the knocksensors, loosen nad reposition the knock sensors orientation position prior to setting the intercooler intake assembly in place so the wiring and sensor would not come in contact with the bottom of the intercooler/intake assembly. If that is not done things can go weird as well. Been there done that. Don't know if this applies with the 05-09 3V setups but would be a good idea to read the installation process again to make sure this was not overlooked in the event it could apply.

I'll shut up now. Hope to see the outcome of this and that I have not muddled things up.

Glasstop09 - please correct my thinking if I have taken a wrong turn in my thought process. I am assuming the the KS's would be low resistance to short to ground internally if they were pegged due to being over tightened and that the sensor harness between C175e and C108 is not damaged.

Assuming - and this is a scary word that the wiring color code is the same (the pin out should be) from 05-09 do a resistance check across the pins as follows.

pin 30 - Dark Green /White stripe

pin 31 - Dark Green / Violet stripe

Pin 48 - Yellow (solid)

Pin 49 - Yellow /Red stripe

This check does not isolate the sensors as the sensors as the problem. It would only confirm an issue with the sensors or wiring prior to yanking 100# of supercharger and intercooler off the engine before knowing if you wish to do any diagnostics beforehand.

As with any resistance check you will need a reliable multimeter. Also assure power is removed from the car. I suggest even disconnecting the battery + as well. You will need to disconnect C175e from the PCM to isolate the circuit from PCM internal resistance.

Last: On the 2015-17 Roush and VMP setups it was important to change the wiring on the knocksensors, loosen nad reposition the knock sensors orientation position prior to setting the intercooler intake assembly in place so the wiring and sensor would not come in contact with the bottom of the intercooler/intake assembly. If that is not done things can go weird as well. Been there done that. Don't know if this applies with the 05-09 3V setups but would be a good idea to read the installation process again to make sure this was not overlooked in the event it could apply.

I'll shut up now. Hope to see the outcome of this and that I have not muddled things up.

Glasstop09 - please correct my thinking if I have taken a wrong turn in my thought process. I am assuming the the KS's would be low resistance to short to ground internally if they were pegged due to being over tightened and that the sensor harness between C175e and C108 is not damaged.

Redfirepearlgt, thanks as usual. Will check everything ASAP, we have family coming over today.

I’m not familiar with the Roush SC, but with the Edelbrock, there are openings between the runners where a borescope can go in and see the KSs and most of the wiring and they look OK.

I’m not familiar with the Roush SC, but with the Edelbrock, there are openings between the runners where a borescope can go in and see the KSs and most of the wiring and they look OK.

Once it's all fixed...and...'back to normal', can the knock sensor sensitivity / threshold be adjusted in the tune? The story I got was when the PD blower is installed, the knock sensor threshold has to be reduced a bit, so it's not false tripping from the blower assy.

The SC has been on for 5 years. It’s been Lito tuned for 4. E85 for almost 3.

Last fall datalog looked good. Engine was rebuilt with forged internals in June. Since then it’s been a comedy of errors. 2 oil leaks, a loose battery cable ( nut not tightened down) at the alternator that caused the car not to shift 3-4 at WOT. Lito’s email server crashed and my emails were not going through until he got new email address, then he went on vacation and just came back this week. Normally, the problem I’m dealing with now should have been dealt with 8 weeks ago. I just looked at the LiveLink datalog, the KC values do go up and down. So when Lito says they are pegged, I believe it is momentary. There are plateaus, not peaks. That’s why he ask me to check exhaust for rattling. I have a digital ethanol gauge and there is 80% ethanol in the fuel, so there should not be this level of detonation.

So now I have to check ALL mechanical connections, along with KS circuits. Otherwise, the car runs great.

Last fall datalog looked good. Engine was rebuilt with forged internals in June. Since then it’s been a comedy of errors. 2 oil leaks, a loose battery cable ( nut not tightened down) at the alternator that caused the car not to shift 3-4 at WOT. Lito’s email server crashed and my emails were not going through until he got new email address, then he went on vacation and just came back this week. Normally, the problem I’m dealing with now should have been dealt with 8 weeks ago. I just looked at the LiveLink datalog, the KC values do go up and down. So when Lito says they are pegged, I believe it is momentary. There are plateaus, not peaks. That’s why he ask me to check exhaust for rattling. I have a digital ethanol gauge and there is 80% ethanol in the fuel, so there should not be this level of detonation.

So now I have to check ALL mechanical connections, along with KS circuits. Otherwise, the car runs great.

redfirepearlgt

forum member

- Joined

- Mar 19, 2011

- Posts

- 2,497

- Reaction score

- 263

I know from experience on the 17 I had that false knock was an issue when doing mods. We had to "detune" the KS's on that car after verifying the fuel was good and that there were no exhaust issues or noise generated on how the car was loaded (strapped down) on the dyno. It is possible that with the change in the rotating assembly to forged internals and upgraded pistons that there will need to be some retuning of the Ks's performed.

Interesting that the Eblock gives you that ability to get down into the unit. I forget that the intercooler is above and not below like on the VMp and Roush 2300 and early 2650 setups before they went a similar route. That does likely give you more room. We had to pull the whole head unit and intercooler on the 17 setup (man I do not miss that heap) to inspect that as well as split the intercooler assembly and clean the oil build up out of it due to the previous owner running it without catch cans. In spite of that work and verifying the fuel was good we still had to detune the KS's on the car to run without pulling timing falsely.

Thanks for the updates and the information. Would love to hear some vid/clips of it idling and running when you are done.

Interesting that the Eblock gives you that ability to get down into the unit. I forget that the intercooler is above and not below like on the VMp and Roush 2300 and early 2650 setups before they went a similar route. That does likely give you more room. We had to pull the whole head unit and intercooler on the 17 setup (man I do not miss that heap) to inspect that as well as split the intercooler assembly and clean the oil build up out of it due to the previous owner running it without catch cans. In spite of that work and verifying the fuel was good we still had to detune the KS's on the car to run without pulling timing falsely.

Thanks for the updates and the information. Would love to hear some vid/clips of it idling and running when you are done.

GlassTop09

Senior Member

Hi redfirepearlgt,

Your resistance process check is spot on using a multimeter so not muddling up anything. Definately easier to access the pins at the PCM C175E connector than the KS siamese connector at the back of B1 cyl w\ IM or blower still installed........

Why I recommended Forscan to check these is that you wouldn't need a MM & don't have to pull IM as Forscan accesses the actual PCM KS voltage PIDs that reads the voltage generated from KS mics off the PCM #1 & #2 KS +- pins in mV thus you can kinda do the same thing.......it's free software as well. Of course, if 1 already has access to tuning software\hardware then no need to get Forscan.

This is highly suspect of your KS mic(s) being over TQ'd to engine block. I assume that all this was working just fine until the engine rebuild.........the rest of this info suggests no wiring or resistance issues between PCM & KS mics thus only leaves a mechanical issue like overtightening\KS mic failure.

Your resistance process check is spot on using a multimeter so not muddling up anything. Definately easier to access the pins at the PCM C175E connector than the KS siamese connector at the back of B1 cyl w\ IM or blower still installed........

Why I recommended Forscan to check these is that you wouldn't need a MM & don't have to pull IM as Forscan accesses the actual PCM KS voltage PIDs that reads the voltage generated from KS mics off the PCM #1 & #2 KS +- pins in mV thus you can kinda do the same thing.......it's free software as well. Of course, if 1 already has access to tuning software\hardware then no need to get Forscan.

Do the KS signal plateaus show as flat spots in signal graphs? Like they go so high then stop & go flat for a time then drop back down? Is this happening w\ only 1 KS mic or both? Is this happening on only 1 cyl or is across all of them?I just looked at the LiveLink datalog, the KC values do go up and down. So when Lito says they are pegged, I believe it is momentary. There are plateaus, not peaks. That’s why he ask me to check exhaust for rattling.

This is highly suspect of your KS mic(s) being over TQ'd to engine block. I assume that all this was working just fine until the engine rebuild.........the rest of this info suggests no wiring or resistance issues between PCM & KS mics thus only leaves a mechanical issue like overtightening\KS mic failure.

GlassTop09

Senior Member

Yes. That's what the per cyl threshold maps are for.......setting the KS sensitivity thresholds per cyl-to-KS assignment. Anything that attaches to the engine that generates any noise\frequency needs to be accounted for in the KS threshold maps or it'll be picked up as a false knock signal.Once it's all fixed...and...'back to normal', can the knock sensor sensitivity / threshold be adjusted in the tune? The story I got was when the PD blower is installed, the knock sensor threshold has to be reduced a bit, so it's not false tripping from the blower assy.

Here is a picture of 1 of these maps opened so you can see w\ an explanation of how this works in GUI below (HPTuners Editor software):

Similar threads

- Replies

- 9

- Views

- 349

- Replies

- 5

- Views

- 257

- Replies

- 1

- Views

- 547

Support us!

Support Us - Become A Supporting Member Today!

Click Here For Details