You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Any thoughts on this Hotchkis K member brace?

- Thread starter Kobie

- Start date

I like those aluminum plates.

As do I. Nice pieces!

What are you guy's opinions on our version?

http://www.bmrsuspension.com/index....cleid=1&maincatid=22&catid=172&productid=1101

dontlifttoshift

forum member

GMitch,

It looks like those are machined from one chunk. If you used a flat plate and then added the protrusions upward as separate pieces with the hardware holding it all together, certainly cost would go down. Then, in my mind, it could be water jetted from flat stock. Even if you had to add some more nutserts for more clamping force I think it would do the job adequately.

On the flip side, I am not looking at the piece, maybe it is more compicated than that.

It looks like those are machined from one chunk. If you used a flat plate and then added the protrusions upward as separate pieces with the hardware holding it all together, certainly cost would go down. Then, in my mind, it could be water jetted from flat stock. Even if you had to add some more nutserts for more clamping force I think it would do the job adequately.

On the flip side, I am not looking at the piece, maybe it is more compicated than that.

Philostang

Chrome Hater

GMitch, maybe you should start a separate thread to gauge interest in the item. That may give you a sense of how you'd want to go about producing them.

A steel version might be cheaper and the stock wouldn't need to be so thick...maybe also easier to make out of several pieces instead of milled out of one...? For my own part, rivnuts are not a problem.

At any rate, if the cost can come down quite a bit, I might be in. To give a sense of your possible target market, if we're talking about $600 then I'd probably be more inclined to fab up something myself. Mull it over. And thanks again for sharing your findings.

Best,

-j

A steel version might be cheaper and the stock wouldn't need to be so thick...maybe also easier to make out of several pieces instead of milled out of one...? For my own part, rivnuts are not a problem.

At any rate, if the cost can come down quite a bit, I might be in. To give a sense of your possible target market, if we're talking about $600 then I'd probably be more inclined to fab up something myself. Mull it over. And thanks again for sharing your findings.

Best,

-j

Kobie

forum member

- Joined

- Dec 23, 2007

- Posts

- 198

- Reaction score

- 7

Is there any reason these plates can't be "built in" to aftermarket K-members?

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Philostang

Chrome Hater

Is there any reason these plates can't be "built in" to aftermarket K-members?

Sent from my iPhone using Tapatalk

That would be the easiest by far. A K-member manufacturer could easily add the relevant extensions to the ends of their mounts to either weld-in or bolt in w/very little modification to the OEM chassis. You could do the same by welding to the OEM K-member legs, but unless you're taking the K-member completely out of the car, it's all overhead welding, and I just hate that... thus, the RIVNUTS! or any other non-weld option is nice.

A pure bolt-in version is a bit trickier from what I can tell. You could just sandwich in a C-channel tube w/extension plates to the relevant chassis (think something like _[ ]_ with the top bridged so it looks more like a hat in cross-section). However, doing that I worry that in dropping the K-member mount 1/8" (or whatever) you introduce other geometry or fitment changes into a slew of other components. So not sure that would work. You could also do the same thing with a smaller "hat" that slips inside the K-member legs & under the existing bolts - that way the K-member itself hasn't changed position at all. You'd need appropriate gussets for such a design, but it may work well that way. I've briefly considered this route. Then there is gmitch's design, the details of which still escape me a bit. There's a bunch I'm not clear on with it, so I don't know how one would go about mimicking or modifying it.

Best,

-j

Roadracer350

forum member

If someone will get me PRECISE measurments I can make these on the CNC here for 1/3 that quoted price guarenteed!! Get me measurments!!! If you dont have the measurments tell me where you got them and I will try and get some and make them in a kit!

Department Of Boost

Alpha Geek

- Joined

- May 26, 2010

- Posts

- 8,809

- Reaction score

- 28

I don’t have any pictures of the plates not on the car (stupid, stupid, stupid). And you can’t really see what is going on when they are installed.

We may be removing one to CAD it up in the next few weeks, maybe.

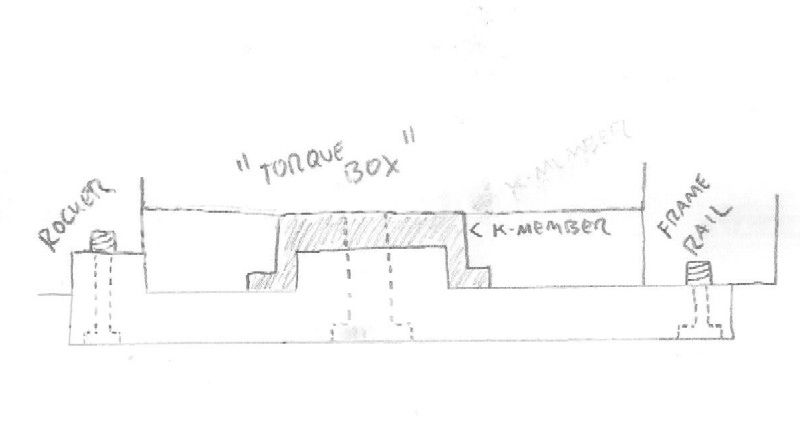

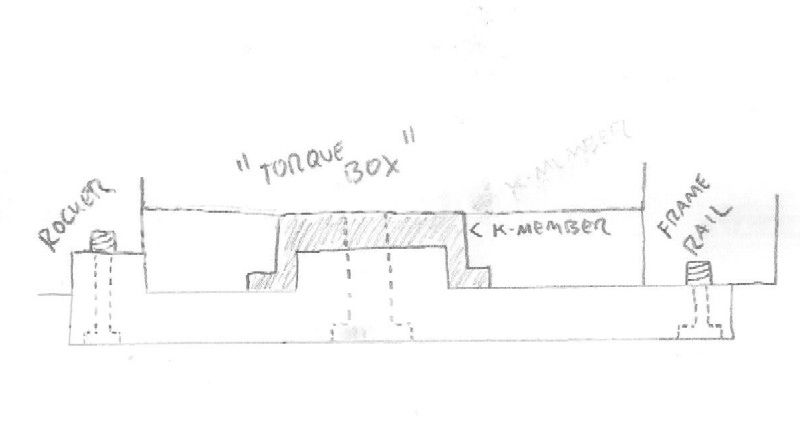

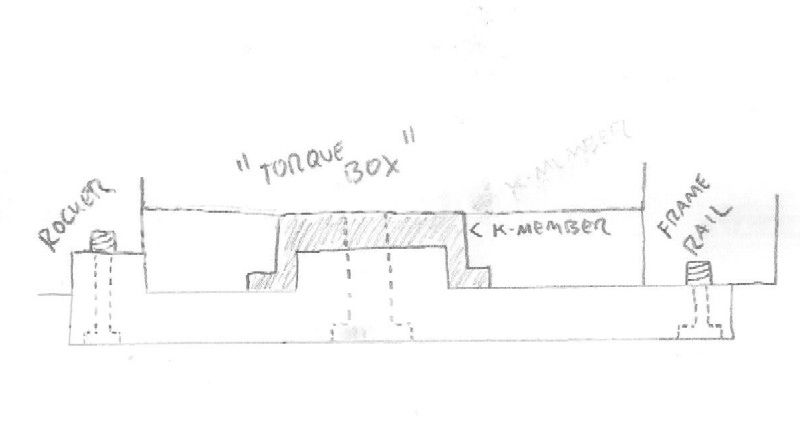

At the end of the day it is pretty easy though. Here is a quick drawing from the “front” of what is tied to what and how. This could be done any number of ways. Billet plate, tubing and brackets, etc. It is impossible to do it as a “bolt on” though, there is nowhere to bolt to. Hence the need for Riv-Nuts. Something could be welded on, but it would need to be at least three pieces though. You would need a bracket welded to the rocker, a bracket welded to the frame and the brace would bolt on. If you welded a one piece brace on you would never be able to get the K-member off again.

We may be removing one to CAD it up in the next few weeks, maybe.

At the end of the day it is pretty easy though. Here is a quick drawing from the “front” of what is tied to what and how. This could be done any number of ways. Billet plate, tubing and brackets, etc. It is impossible to do it as a “bolt on” though, there is nowhere to bolt to. Hence the need for Riv-Nuts. Something could be welded on, but it would need to be at least three pieces though. You would need a bracket welded to the rocker, a bracket welded to the frame and the brace would bolt on. If you welded a one piece brace on you would never be able to get the K-member off again.

Department Of Boost

Alpha Geek

- Joined

- May 26, 2010

- Posts

- 8,809

- Reaction score

- 28

If someone will get me PRECISE measurments I can make these on the CNC here for 1/3 that quoted price guarenteed!! Get me measurments!!! If you dont have the measurments tell me where you got them and I will try and get some and make them in a kit!

You can't buy the materials for that. What you have to start with is a LOT bigger than you can see in the picture.

Last edited:

Roadracer350

forum member

You can't buy the materials for that. What you have to start with is a LOT bigger than you can see in the picture.

I have scrap here bigger than that piece! LOL! We get HUGE discounts because we buy in such volumes.

Roadracer350

forum member

I don’t have any pictures of the plates not on the car (stupid, stupid, stupid). And you can’t really see what is going on when they are installed.

We may be removing one to CAD it up in the next few weeks, maybe.

At the end of the day it is pretty easy though. Here is a quick drawing from the “front” of what is tied to what and how. This could be done any number of ways. Billet plate, tubing and brackets, etc. It is impossible to do it as a “bolt on” though, there is nowhere to bolt to. Hence the need for Riv-Nuts. Something could be welded on, but it would need to be at least three pieces though. You would need a bracket welded to the rocker, a bracket welded to the frame and the brace would bolt on. If you welded a one piece brace on you would never be able to get the K-member off again.

So the center just bolts where the existing K member bolts in correct? The other 2 mounting locations bolt to the outside and the inside frame members.

ocpony

forum member

- Joined

- Feb 3, 2008

- Posts

- 159

- Reaction score

- 0

I had a collapse also of the inner portion of car attachment points after a tire changing company jacked the car under the kmember attachment point on my 2005 mustang. I had BMR kmember on it at the time. After studying how to repair it I determined that the attachment point may be intentionally made weak as a crash or safety feature. I believe it is designed to allow the engine/tranny component to be driven downward as opposed to into the firewall and cabin area in order to help protect the occupants.

I like the plates as an idea to strengthen this area for a race car but you may not want to for a daily driver. Just my .02 cents. The structure that locates the "nuts" that the kmember bolts into is just thin sheet metal in a vertical wrap around the "nuts" and is easily deformed by vertical forces such as jacking.

My repair was to pull the mounting point back down as close to the original point as possible and then I took some 1/16 plate and welded it to the rocker and frame rail. It had to be bent and tweaked to fit right and then drilled for the kmember bolts to pass thru. I was only trying to beef it up a little in case somebody else ever jacked it there again and I didn't want it to collapse again.

I like the plates as an idea to strengthen this area for a race car but you may not want to for a daily driver. Just my .02 cents. The structure that locates the "nuts" that the kmember bolts into is just thin sheet metal in a vertical wrap around the "nuts" and is easily deformed by vertical forces such as jacking.

My repair was to pull the mounting point back down as close to the original point as possible and then I took some 1/16 plate and welded it to the rocker and frame rail. It had to be bent and tweaked to fit right and then drilled for the kmember bolts to pass thru. I was only trying to beef it up a little in case somebody else ever jacked it there again and I didn't want it to collapse again.

If someone will get me PRECISE measurments I can make these on the CNC here for 1/3 that quoted price guarenteed!! Get me measurments!!! If you dont have the measurments tell me where you got them and I will try and get some and make them in a kit!

The last time you made that claim you soon backtracked and never made anything.

You're going to offer to steal the materials and use company machinery without paying for it and offer it for sale? Hope you boss doesn't see your posts you'll be looking for a job.

....After studying how to repair it I determined that the attachment point may be intentionally made weak as a crash or safety feature.......

I agree with you and it would have to be made clear like many aftermarket parts you use it at your own risk and as they say for racing only.

Roadracer350

forum member

The last time you made that claim you soon backtracked and never made anything.

You're going to offer to steal the materials and use company machinery without paying for it and offer it for sale? Hope you boss doesn't see your posts you'll be looking for a job.

No I actually made the splitter. Its just hard to get into the garage when we have only had a couple days that it has not been in the 30s here. No one on here showed much intrest. If you want me to make you one I can. The splitter I make myself at home but parts like this I will run it thru the comp. The more money I make them the more money I make plus I hold stock in the comp.

Department Of Boost

Alpha Geek

- Joined

- May 26, 2010

- Posts

- 8,809

- Reaction score

- 28

I’m thinking he is referring to when you said you were going to make these for cheap, checked on materials cost and then didn’t.No I actually made the splitter. Its just hard to get into the garage when we have only had a couple days that it has not been in the 30s here. No one on here showed much intrest. If you want me to make you one I can. The splitter I make myself at home but parts like this I will run it thru the comp. The more money I make them the more money I make plus I hold stock in the comp.

Roadracer350

forum member

On those yea the material and machining made those more than most would be able to afford. That material you would have to have a 4x8 sheet of alum and would only get 2 units out of it. I can do them but I will have to have a couple orders before I can justify to make them. These plates are pretty easy the hardest part would be the Pem Nuts. The customer would need the install tool. Not sure if Autozone or Pep Boys would have that in the loaner tools.  Im still wanting to make one for mine but I am waiting until we have a big enough piece of scrap that I can get for like 25 bucks!

Im still wanting to make one for mine but I am waiting until we have a big enough piece of scrap that I can get for like 25 bucks!

Im still wanting to make one for mine but I am waiting until we have a big enough piece of scrap that I can get for like 25 bucks!

Im still wanting to make one for mine but I am waiting until we have a big enough piece of scrap that I can get for like 25 bucks!Department Of Boost

Alpha Geek

- Joined

- May 26, 2010

- Posts

- 8,809

- Reaction score

- 28

If someone will get me PRECISE measurments I can make these on the CNC here for 1/3 that quoted price guarenteed!! Get me measurments!!! If you dont have the measurments tell me where you got them and I will try and get some and make them in a kit!

How about this. I will send you prints/3D models and you make me three sets of them for $600 ($200/set) in trade?

Shouldn’t be an issue with free material.

Roadracer350

forum member

The free material is for me!!  If you have some general measurments and hole locations just draw out a sketch and get it to me and I can make the prints and DXF file then from their I can get a general idea on what they will cost. If their is enough intrest I can order a 4x8 sheet of T6 and do the entire sheet and that will cut the cost down. From the rough drawing I have I am thinking .750" Material. We may be able to have the OD laserd out and finish them on the mill. Looks like it would be a single opp on the mill so that will cut the cost down. If not no biggy I will try and take some measurments this weekend it is finally warming up here.

If you have some general measurments and hole locations just draw out a sketch and get it to me and I can make the prints and DXF file then from their I can get a general idea on what they will cost. If their is enough intrest I can order a 4x8 sheet of T6 and do the entire sheet and that will cut the cost down. From the rough drawing I have I am thinking .750" Material. We may be able to have the OD laserd out and finish them on the mill. Looks like it would be a single opp on the mill so that will cut the cost down. If not no biggy I will try and take some measurments this weekend it is finally warming up here.

If you have some general measurments and hole locations just draw out a sketch and get it to me and I can make the prints and DXF file then from their I can get a general idea on what they will cost. If their is enough intrest I can order a 4x8 sheet of T6 and do the entire sheet and that will cut the cost down. From the rough drawing I have I am thinking .750" Material. We may be able to have the OD laserd out and finish them on the mill. Looks like it would be a single opp on the mill so that will cut the cost down. If not no biggy I will try and take some measurments this weekend it is finally warming up here.

If you have some general measurments and hole locations just draw out a sketch and get it to me and I can make the prints and DXF file then from their I can get a general idea on what they will cost. If their is enough intrest I can order a 4x8 sheet of T6 and do the entire sheet and that will cut the cost down. From the rough drawing I have I am thinking .750" Material. We may be able to have the OD laserd out and finish them on the mill. Looks like it would be a single opp on the mill so that will cut the cost down. If not no biggy I will try and take some measurments this weekend it is finally warming up here.

Similar threads

- Replies

- 5

- Views

- 251

- Replies

- 8

- Views

- 798

- Replies

- 32

- Views

- 7K

Support us!

Support Us - Become A Supporting Member Today!

Click Here For Details