I'll keep it short. We have not released sway-bars for the 2011+ Mustangs. We decided to hold-off due to our higher volume parts needing attention for the newer 2011+ models.

We are going to be releasing Front and Rear Sway-Bars soon for 2005-Current S197's.

We have designed a few different styles, and considered a few different mounting styles/locations. For the sake of not wanting our ideas to be ripped off, I do not really want to share them all....but they are all innovations, I promise.

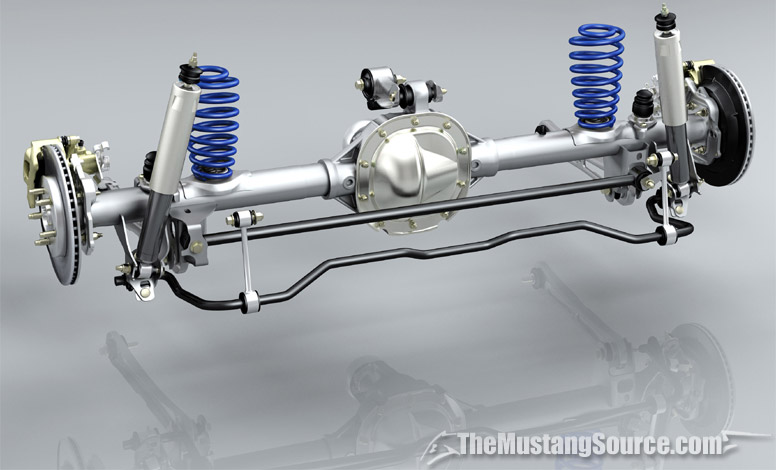

We do not want to produce an axle mounted bar, if all possible. We like axle mounted bars for many applications, and actually built/SOLD them for the S197 back in 2004/2005....but we just think the mounting to the axle is working backwards in technology.

This is the version we ran in 2004.

We are not lacking knowledge here, we are simply wanting to ask you, the customer, what do YOU want for a Sway-Bar set-up?

-Rates? (apparently people are wanting "super-stiff" rear bars?)

-Price Point? (we could make $700+ bars, but, you don't want that, right?)

-Mount Location? (reasons; clearance, ease of install, etc)

-Weight (we will probably do both hollow, F/R)

-Adjustable (how stiff do you want/need?)

-Bushing Mounts (Billet Mounts? Cheaper Steel Mounts?)

-End-Links (Billet Aluminum? Steel?)

Pros/Cons of all the bars available?

The primary reason for this is simple. We definitely realize that we have been slow to market with this portion of the suspension, since the release of the 2011's, and feel it has inconvenienced our customer base drastically, so, tell us what you want. We will compile everything, make a sound decision, and make them available to the market.

Let's talk sway-bars! Heck, bring all the threads about sway-bars over here....compare the current ones, whatever you think or have to say about the bars for 2005-Mustangs, post up.

For those that participate, thank you.

We are going to be releasing Front and Rear Sway-Bars soon for 2005-Current S197's.

We have designed a few different styles, and considered a few different mounting styles/locations. For the sake of not wanting our ideas to be ripped off, I do not really want to share them all....but they are all innovations, I promise.

We do not want to produce an axle mounted bar, if all possible. We like axle mounted bars for many applications, and actually built/SOLD them for the S197 back in 2004/2005....but we just think the mounting to the axle is working backwards in technology.

This is the version we ran in 2004.

We are not lacking knowledge here, we are simply wanting to ask you, the customer, what do YOU want for a Sway-Bar set-up?

-Rates? (apparently people are wanting "super-stiff" rear bars?)

-Price Point? (we could make $700+ bars, but, you don't want that, right?)

-Mount Location? (reasons; clearance, ease of install, etc)

-Weight (we will probably do both hollow, F/R)

-Adjustable (how stiff do you want/need?)

-Bushing Mounts (Billet Mounts? Cheaper Steel Mounts?)

-End-Links (Billet Aluminum? Steel?)

Pros/Cons of all the bars available?

The primary reason for this is simple. We definitely realize that we have been slow to market with this portion of the suspension, since the release of the 2011's, and feel it has inconvenienced our customer base drastically, so, tell us what you want. We will compile everything, make a sound decision, and make them available to the market.

Let's talk sway-bars! Heck, bring all the threads about sway-bars over here....compare the current ones, whatever you think or have to say about the bars for 2005-Mustangs, post up.

For those that participate, thank you.

lol

lol