2013DIBGT

I Hate Wheelhop

Roush's anti-wheel hop kit is in a unique position. The bushing durometer is inbetween OEM and poly yet has a lower hole on the mount to increase AS. You would have to put a spherical on the diff side to reduce bind as it obviously doesn't articulate, but you would wind up with increase AS and certainly a lot less NVH than a poly. I would be assuming that bind wouldn't be introduced until the spherical at the diff reached max travel and started binding. How far that in travel until that happens, I have no idea.

Yeah, I was eyeballing the Roush UCA kit myself during the initial planning phases of my suspension build and considered using it in combination with the Maximum Motorsports Extreme LCA's which use Sphericals at both ends. I read of a few other folks running that setup with success and had minimal NVH increase.

Ultimately I choose to not go that route because I feel the TA setup appears to be a far more durable option when used with whatever flavor of LCA / Relo bracket that is chosen. I guess I'll know soon enough if my gut feeling was right or wrong.

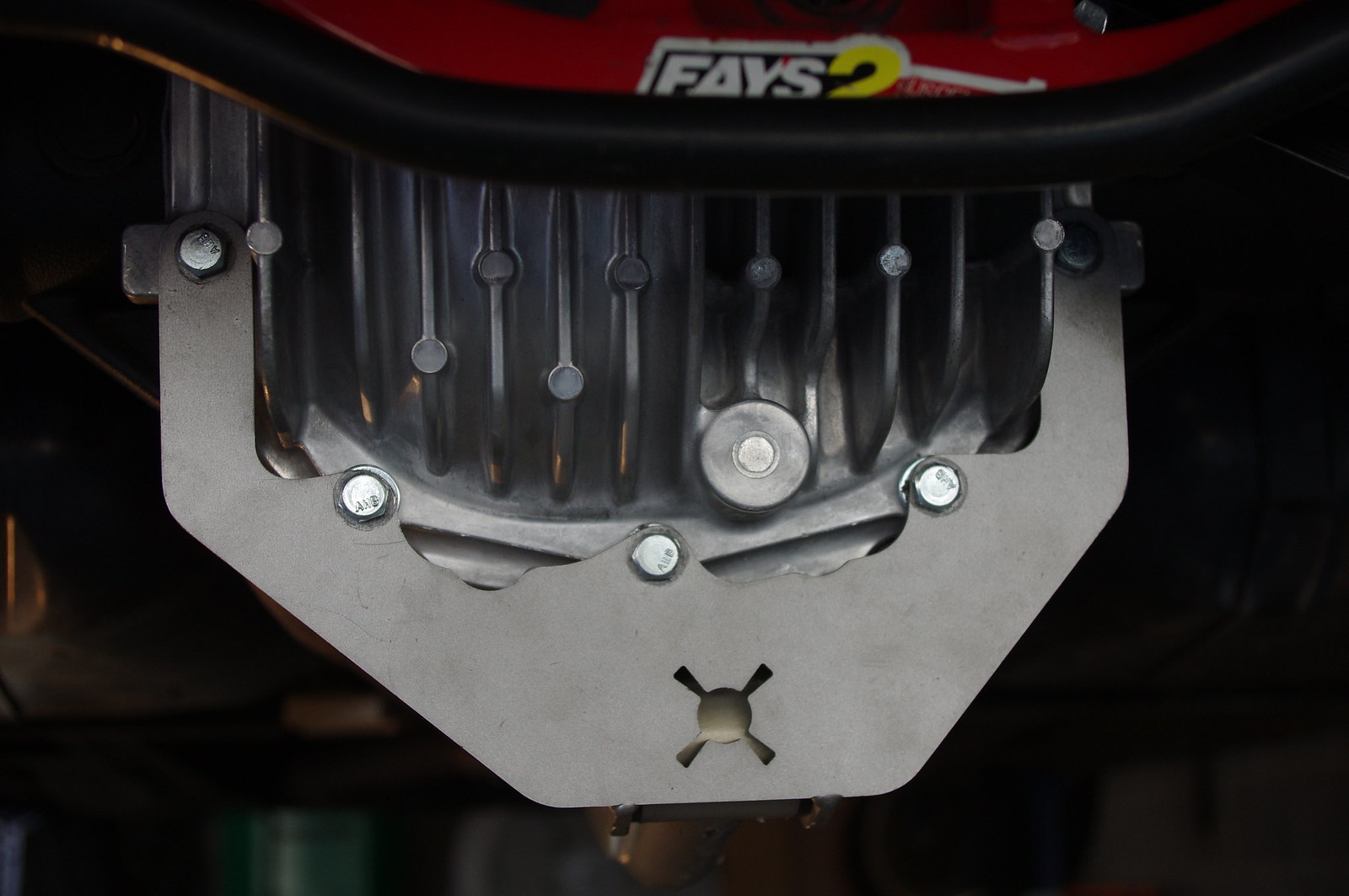

In my case, I'm sold on the whole Cortex rear end package because it is just that, a package designed to work together using components tested with each other to provide a complete solution.

I've done the piece meal setups in the past and while they certainly worked they were almost always more difficult to install due to parts not always lining up just right at which point I would find myself saying "I should have gotten that damn package from brand X instead" while I'm seeing Red

hammering the shit out of a bolt that should just go right in.

hammering the shit out of a bolt that should just go right in.