GlassTop09

Senior Member

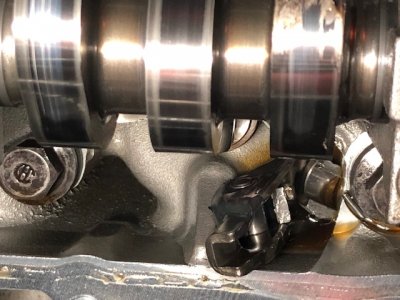

Dino is correct.......those are the cam follower roller bearings from a busted cam follower......more evidence to confirm what your prior pictures show evidence of.Hey Dino, I changed the oil after all this happened. And the old oil did not have any metal debris. Though, I found 2 pin bearings (see image). I also took measurements.View attachment 83295 View attachment 83296

Several conditions can cause this, but not all are due to engine timing being off. With this design, if this was due to physical crank to cam timing being off on a bank & the culprit is intake valves then you should have not 1 but 2 intake valves damaged since both intake valves per cyl are operating on same ICL & you'll also have damage in more than 1 cyl on the same bank as well. From your given analysis & pictures I would surmise that engine to cam timing ain't your cause of a single intake valve strike....failure would be constrained to a single valve scenario (why a visual into the cyl head intake ports for damage will help to confirm as well as visual inspection of upper valve train for damage before pulling off head......you'll have to pull both intake manifold & valve cover off anyway so makes sense to start w\ these 2 areas to get damage assessment as well as root cause analysis).Thanks.

What would cause an intake valve strike on the piston? I am asking this question because ModularHeadShop did all the work on the heads. All I had to do was install them and line up the timing marks on the chain.

So off the top of my head, a valve spring collaspe causing cam follower to come out & get damaged & valve hang open, cam follower failure causing valve retainer keepers to come out & drop valve, cam follower failure causing valve stem bend to hang valve open, intake valve stem structural failure causing valve to drop & cause cam follower to come out & get destroyed, etc.....can all cause what you're seeing so the only way to determine exactly what happened is to remove the intake manifold & valve cover to inspect all parts, not just the damaged ones but all of them for any clues then replace any\all parts that are determined to have played a part in this to help prevent this from happening again.

2 questions from me........when you replaced the heads, did you also replace all the cam followers\lash adjusters w\ new ones or did you reuse the existing ones? Are the cams stock or aftermarket & if aftermarket which ones?

Hope this helps to answer your question somewhat.