Not trying to call you out on this sharad but i dont see how in any kind of way the lca brackets will put more force on the rear. I would say yea if they moved the leverage further out torwards the tire, thus creating the old cheater pipe effect and making axle tubes longer and putting more stress where the tubes are pressed in the center chunk.

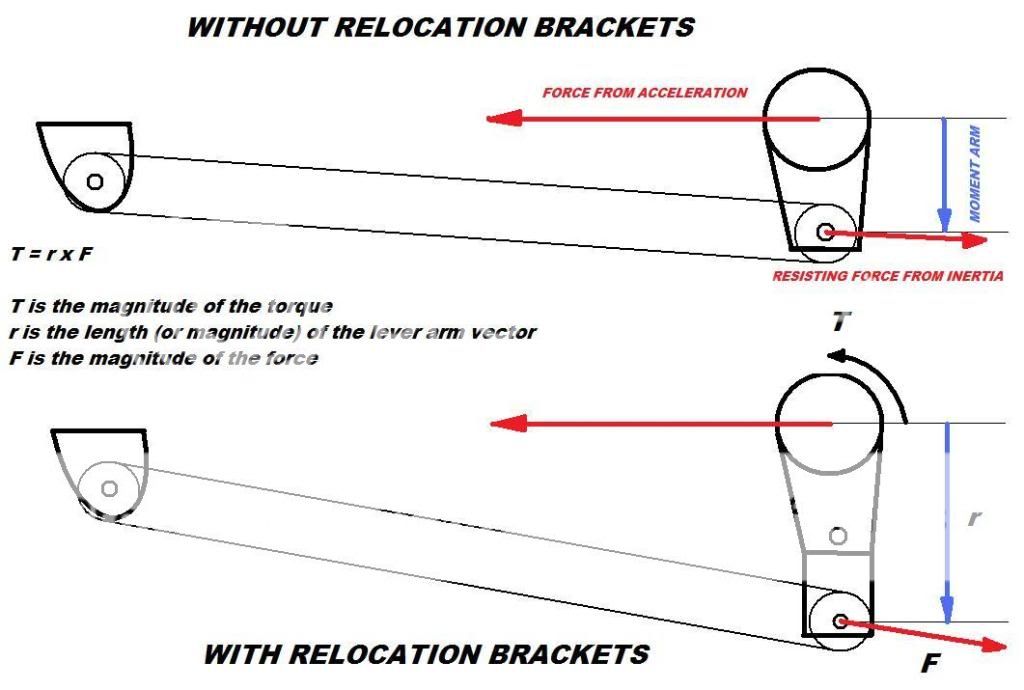

I just spent WAY too much time drawing this diagram... but hopefully it will make sense. When you increase the distance between the control arm bolt and the axle, you increase the leverage that the control arm has on the axle housing.

This diagram is a simplification of what all is going on in there, but it is a crude representation of how the forces act on the axle tube. Basically, the axle tube is trying to move forward, the weight of the body of the car (inertia) is resisting that motion, so it's pushing straight back, through the lower control arm. The force that the LCA puts on the axle housing is the same before and after the relo brackets, but when you increase the distance from the control arm bolt to the axle by adding the relo brackets, you give that force more leverage on the axle, so it makes it easier to twist the axle tube.

If you imagine that your LCA

mount is a ratchet and the LCA is your hand, then you can imagine trying to break a bolt loose that was torqued down to 100 lb-ft. Hold the ratch 6" away from the bolt and you can't turn it. Then hold the ratchet 12" away from the bolt, and you can finally turn it. It's because you have more leverage.

The LCA relo brackets give the LCAs more leverage on the axle tube, so they make it easier to twist the axle tube. Obviously, S197s have an issue with the axle tubes twisting. (although, strangely, our 4000# 2010 has been 9.90 @ 133 with a 1.35 short time on the stock housing with no issues) If you know the cars already have an issue with twisting axle tubes, then you're just asking for trouble when you install the relo brackets. But

Kelly is right, if you weld the axle tubes, you'll decrease the likelihood that your axle tubes will twist out.

If a person is planning on drag racing alot welding the axle tubes and good ford racing diff cover will def stiffen things up and save alot of possible failures.

Agreed, although I'd recommend the UPR diff cover.

Not trying to say one shop is better than the other but instant center brackets of any quality brand is gonna help your 60 ft times. Having more adjustments to the rear suspension helps tremendous and the LCA brackets with multi adjustments can control how hard you hit the tires, everyone knows drag slick and drag radials are two diff beasts at the starting line, just ask all the guys who run x275 stock style suspension cars. Just like a n/a aluminum block 5.0s instant center will be different than an iron block nose heavy gt500. Point blank, more adjustments the better.

Did you see the post I made on UPR's facebook page today? Jake Conant's '03 Cobra was running 60-foot times in the 1.4Xs. He wanted to hook harder, so he bought one of those fruity UCA relocation kits. His best 60-foot time on them slowed to a 1.52. Then he removed the relo junk and installed a straight forward UPR Pro Series setup and the car responded with a 1.30.

Suspension setup is a very complicated thing. More adjustment holes don't always equal quicker ETs.

I've said it before and I'll say it again, I understand the use for relo brackets and their multiple adjustment holes... but if our car goes 1.35 without relo brackets, and on street style suspension and radials, then I don't feel relo brackets are "necessary" to make these cars hook.

It's not about us vs. them. Some people like PD blowers, some like centrifugals. Some people like UPR, some like BMR. That's perfectly fine with me. There's room for all of us in the market.