Left: Ryan and I washed the Mustang Friday. Right: He also made a swaybar change on Mark's car for Sunday's Mirrorkhana autocross

So Sunday began early once again, but this time at least I wasn't hung over, so that was a huge plus. I was scheduled to go out in the Mustang in the very first TT session then hand over the keys to Amy for the rest of the day. She wanted some track time to make up for the missed Sunday TT session I was taking, so she was going to head out with the TT3/4 folks right after I ran. We added some fuel and I got to grid early, parking next to Mike Weathers' TT1 Corvette once again. Damn that LSx motor sounds GOOD at idle... you can hear that monster idling at the start of my two in-car videos, and it isn't the stock 5.0L V8 in my car, ha! Our A6s were still fresh but wearing quickly, and I wanted to leave plenty of tire left for Amy, so I told her and the guys I would only take ONE LAP. To keep from overheating the tires on the out lap I also did no scrubbing of the tires (rapid slalom motions) on the warm up lap, and just put-putted along, with just some warming of the brakes. I wanted the A6s nice and cool when my hot lap started. We get the green flag at Turn 13 on our warm up lap, and that's when I laid into it and actually nailed the Turn 13-16 complex correctly on the warm up lap. I was catching up to Mike's TT1 car coming onto the front straight so he let me by right as we took the start/finish on hot lap 1, as shown below...

The video above is my one and only TT hot lap on Sunday, and it was another 1/2 second quicker than my best on Saturday. Hot damn, that was rush! All of the stars were aligned and I didn't over-drive T13-T16 on the previous lap or my hot lap. The temperatures were the coolest of the day (59°F) and that always helps performance with the A6. Brandon was able to get the data from the AIM Solo meshed it to the on-board video this time, using the Dashware software we bought a while back (thanks for the tips, KenO!), but it brought the video quality down a tick in the process (we're working on that). Not much to show other than GPS speeds, a running lap timer clock and the track map. We're working on getting the lateral and fore-aft g readings shown on the next round of videos from a future track event.

Sunday TT Results: http://timingscoring.drivenasa.com/N...ay%20Final.pdf

This 1:50.535 reset the TT3 track record for the weekend and would hopefully stand up for the day. Amy finally got a chance to drive the car and kept dropping time all day, as she got more and more laps under her belt. She ran an HPDE3/4 session, TT session 2 and TT session 3. It was getting too warm to drop much more time and she stuck with her best lap of 1:54.1 in TT session 3. She skipped session 4 so we could get on the road sooner, and she, Ryan and Brandon loaded the car while I rode with my HPDE1 student on her 8th and final track session of the weekend, late on Sunday.

While Amy was running the rest of the day in TT, I was watching the Race Monitor app on our tablet for real time lap data during the TT run groups, always with a nervous eye on TT3 times. Eric "Trigger" Trigg (above left) dropped a lot of time on Sunday in his TT3 C5 Z06, which he drives to the track, and managed a 1:52.702 on Sunday - his new personal best at this, his home track, and good enough to take 2nd place in the class on Sunday (plus a free tire from Hoosier!). Dysen Pham got a 1:53.257 in his well prepped S2000 to take 3rd. John Roberts (below left) had a wheel bearing take a dump on Sunday and slowed down to a 1:53.930 to take 4th (he is building an all new LS1 Miata for the next event, so look out!). We had a total of 8 cars in TT3 on Sunday, again the biggest TT class, but Amy isn't shown in the TT results (yet). She would have placed 5th - eventually the T&S folks will get the results sorted out (her laps are shown in MyLaps but not the official results). We switch both the numbers on the car and run 2 different AMB transponders, so the data is there for them once they get a chance to sort it all out, but having 2 drivers driving the same car on the same day is always confusing.

By the end of Sunday my first lap mad dash held up and this was good enough for another win, new track record and 2 more tires from Hoosier. Which is a good thing, because we are eating through A6 tires like mad.

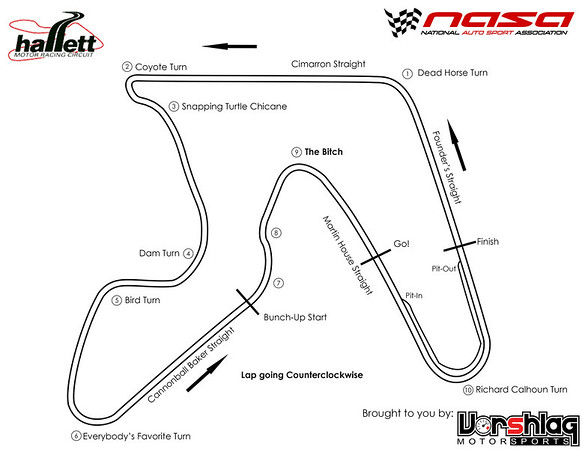

The GT1/Super Unlimited Mustang above is a real monster - 750 whp V8 in a wide bodied S197 with the same 355 Hoosier slicks we have in store for our E46 LS1 car. This Terlingua team always put on a good show and driver Mike Stacy didn't disappoint, with a 1:46.893 in Sunday's race. They are based out of Oklahoma and Hallett is their home track, so I'm sure we will see them again at the NASA @ Hallett event on June 22-23.

Time Trial Tires: Hoosier A6 vs R6 or Kumho V710?

We did a lot of damage to a new "sticker set" of Hoosier A6 tires at this weekend, once again. We also did a lot of damage to new sets at TWS, MSR-H and MSR-C. Sometimes we can stretch a set for 2 weekends, but usually it is more like 1-1/2. We are not alone in our tire wear woes - but ask ANY racer and they will likely complain about tire costs, right? But tracking a Hoosier A6 - a tire designed and built for super short heat-up times, for autocrossing - is kind of an unusual thing, but it has become the norm at the pointy end of the grid in TT. We have dubbed it the "TT Arms Race", which has escalated from running NT-01s to R6s to A6s... if you bring a sticker set of A6s then your competitors will likely do so at the next event, too.

A Hoosier R6 has a much longer lifespan on track, as it was designed to shed heat over may laps, and not just "OMFG heat up right now!" for an autocross run like the A6. Since autocross runs usually only lasts 30-60 seconds a tire made for that needs to heat up VERY quickly. Running an A6 on track can be done but they have severe limitations, and I'm not sure it is worth it if you aren't winning the tires. We are currently testing and "learning new tracks" using A6s, which isn't a smart use of tires. We should be testing and learning the track on a better wearing tire like an R6 or the Kumho V710, so we have another set of wheels on order for that very use (hopefully we will have them by the Hallett event). And another set of wheels for dedicated Hoosier Wets would be nice - so we have some Wets tires coming that we will mount to a set of D-Force 18x10s. John Robert's tire management was much better than ours at the NOLA event and we've got to be more mindful of the limited lifespan of the A6, because we won't win 4 new tires every weekend.

Other Challenges and Development

The Mustang is hardly maxed out for TT3 - far from it. This is still mostly a street car, with many of the parts on it from our ESP autocross set-up, but I am pushing Amy to let us develop it into a bit more of dedicated TT3 build. It still has A/C, touch screen Navigation, is 100% emissions legal, bone stock engine, stock clutch/pp/flywheel, stock driveshaft, stock cooling system and stock brakes (with just pads/fluid/front ducting). There are many MANY aspects we can maximize and improve, and most of those are to deal with existing issues we uncover as the car gets faster.

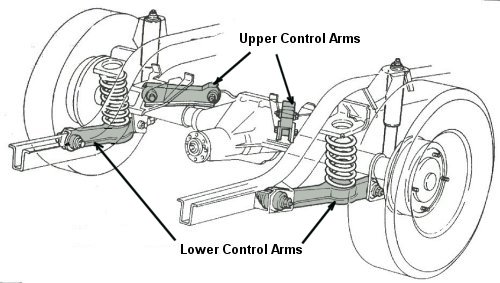

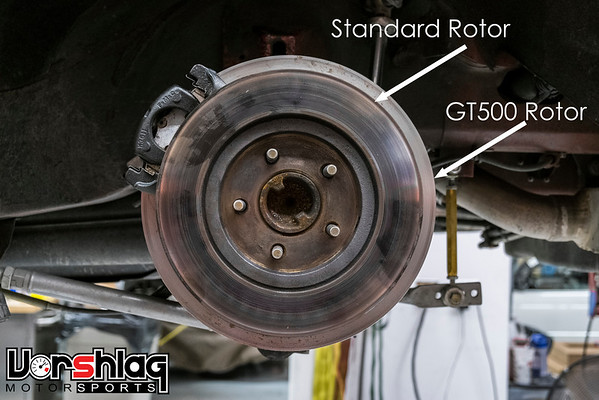

We didn't make substantial parts changes to the car before this event, for once, but that doesn't mean we didn't work on the set-up. As I wrote above, Ryan and Brandon helped take tire pressures and temps all weekend, with changes made to the tire pressures and front camber to get the temps looking better. Brake temperatures were also VERY high in the rear, so we are looking at going with a larger rear brake rotor and adding rear brake cooling. A wider tire would help with mechanical grip, so we're exploring a wider wheel up front (currently 18x11") to possibly match the 18x12" wide rear. And the aero set-up needs a lot of help.

It is apparent when you drive the car that the rear is making more downforce than the front, which turns into a high speed push. Very noticeable at NOLA in turns T2, T8, T9, and T10. To add substantial front downforce will take a lot of work, but we are looking into it. It would be nice to pull some weight off of the front axle as well, but this is also easier said than done.

There are some more things in the works but it is too early to discuss them. Oh, and all of you asking about the Whiteline transmission insert for the Getrag 6-spd on the 2011-2014 GT and Boss302s, we are still waiting on the production order we placed many weeks ago, and I was just told it is about 90 days out - sorry. If you have called or e-mailed us we have you on our waiting list. Thanks for your patience.

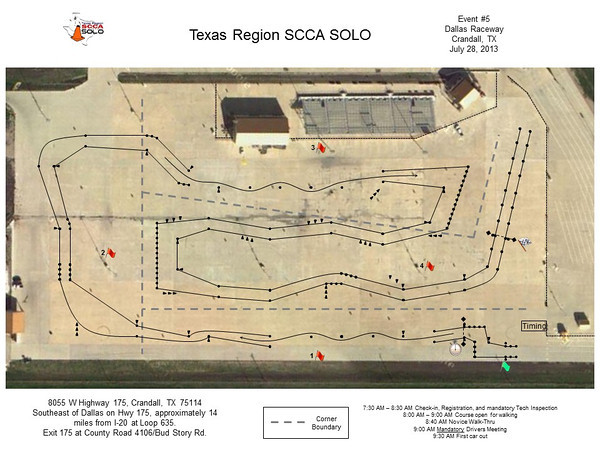

The next NASA event we plan on attending is the June 22-23 at Hallett in Oklahoma, then there is another Five Star Ford sponsored track event at ECR June 29. It is getting HOT in Texas so hopefully that is all we do for that month, but we do get pulled into events at the last minute sometimes. We have actually entered and competed in two more events since NOLA (Five Star Ford car show May 18th and SCCA Autocross May 19th), but I don't have time to do the event write-ups just yet so I will save those until next time. We have been busy working on some Vorshlag shop vehicles (like the BMW 740iL and GMC 1500 Parts Runner, the 2013 BRZ, as well as big leaps forward on a few LS1 BMW swaps and the Miata LS1 prototype. I will also cover more on the 2013 GT in the next update, which has undergone a beauty make-over and I am picking it up tomorrow.

Thanks for reading,

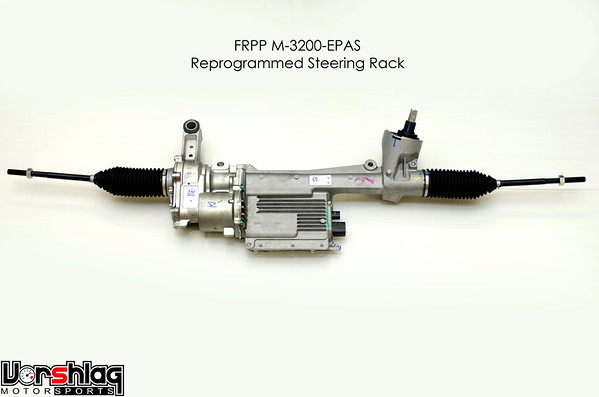

And our kit has OEM quality, reliability, and costs $100 less.

And our kit has OEM quality, reliability, and costs $100 less.