I have a BMR 2-hole upper mount and bought this Roush/BMR boxed rear upper with spherical bearings (R06030069). While I trust the part was correctly engineered and feels very strong, it does have an issue I feel compromises its integrity for 800hp launches on slicks. What do you think?

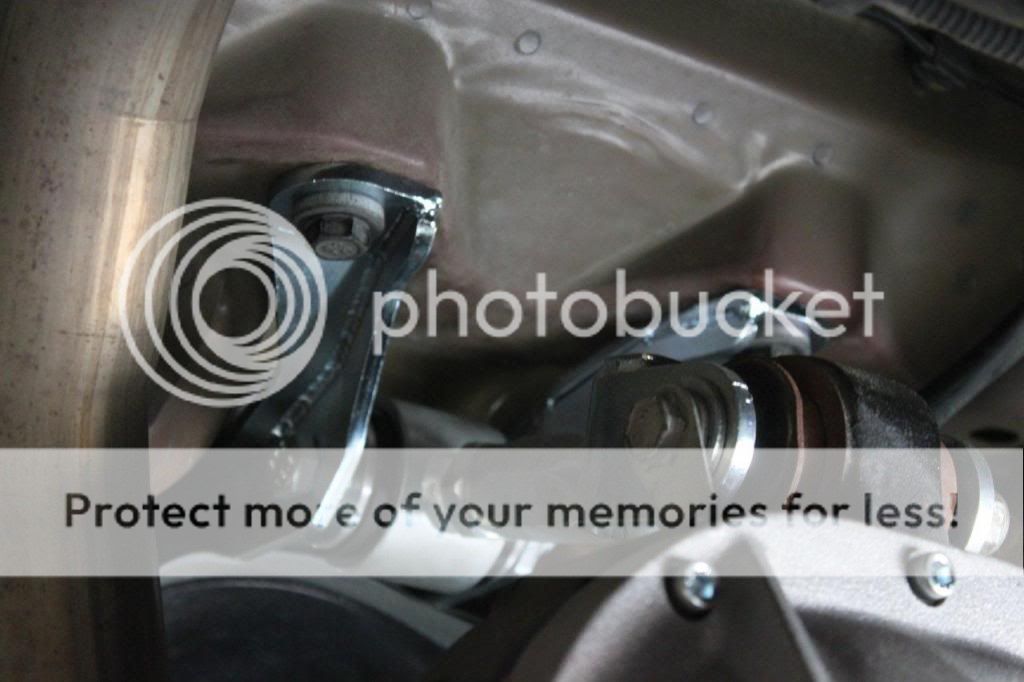

The first pic is to give you an idea of what part I am dealing with. The second pic points to the exact spot in question.

Where the sheet/plate of metal is bent to form each one of the ends on the rear axle bushing side, after the arched cut-out section, the ends are bent at 90 degrees and there appears to be a ground-off weld at the crease that "straightens" the tab that the rear axle upper bolt goes through. One side (in the first pic) seems fine/no slit/ground smooth, but the other has very obvious lack of weld penetration. I can see the slit used to allow the heavy sheet to bend over the side. The weld is ground smooth on the other side, but you can see the slit is at the worst possible location to tear-out.

Am I being too cautious? Is this a failure waiting to happen?