Back@itagain

forum member

There are to many casting changes in the intakes. Kenne Bell can cast 100 of them and there could be differences between all of them. There are to many variables between all the manufactures and that is the reason they made their port program around the stock intake.

Exactly...and the exact reason they should not have cut the ports so large not to mention the inner diameter of the gasket is what it is and is manufactured by the OEMs. As a manufacturer Livernois should know to leave some wiggle room just like Mike Schroop stated in his previous post.

Since Im here I figure I may as well expound upon my last post. In summary, on January 31, 2012, Dan Millen and Rick LeBlanc called me to discuss this issue. Right off the bat Dan indicated, in not so many words, he thought mine and "that girl's" (regarding stang06girl), posts and pictures were ridiculous. As the conversation continued, Dan indicated the port design was made using the stock manifold. He inidcated they were able to see the gaskets seated right up against the edge of the cut port.

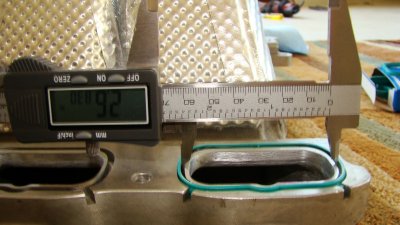

On February 15, 2012, I had scheduled a meeting with Mike Schroop and Dan Millen to discuss possible solutions to the predicament Livernois has put me in. I arrived and Mike was the only one available. In my opinion, Mike has done a great job communicating with me to try and resolve the sealing issue and he continued to do so on this date. Mike said he was unable to find measurements similar to what I had stated. Then he went back into the programming in the CNC machine which, according to Mike, was previously used to produce the stage 3 cylinder heads but is no longer. This is where Mike found some useful information.

Mike filled me in on some additional background which brought everything full circle. Livernois was previously developing a stage 3R cylinder head. Sort of a "max effort" with very large intake ports, different valve seats and the sort. This effort was terminated due to the sheer economics. Too much money to develop not enough in return type thing; however, the CNC program remained and was in the machine cutting heads for a period of time. According to Mike, Livernois has since changed to one of their other CNC machines to produce their stage 3 heads which is cutting a port of 2.57".

Jumping back to the January conversation. Dan suggested using Devcon to fill in the machined gasket grooves and then re-CNC them. For the reasons I previsouly posted (pretty sure I did. I've exchanged so may emails now with Mike that I forget where I posted it), I found this to be unacceptable. Not wanting to waste another season with build problems and seeing an agreable solution was not forth coming, I found an acceptable potential resolution on my own prior to meeting with Mike and after the January conversation.

While at Livernois talking with Mike (back to February) we also discussed options. 1) Livernois replaces these cylinder heads for several reasons. First, is the obvious. They dont properly seal to the manifold which they also sold me. Second, when I built the car I waited for the new castings at Dan's suggestion. Dan and I discussed the new castings and CNC program at length since it was creating an extremely long delay on my build. After the first set had problems, these were swapped with out my knowledge for the old style casting when they swapped out the cylinder heads with valve guide/seal issues. I didn't find this out until the car was returned to me and I tried to pull the plugs to read them. Surprise, surprise...out came the 2 piece barrel style spark plug. I called Dan immeditately and he told me he didn't realize I had originally specified the new style cylinder head castings and gave me a laundry list as to why the did it...convenient memory loss! Third, I still have a suspect valve guide seal which should be addressed.

2) They think up a figure, I think up a figure and I would take a "buy out" and be done.

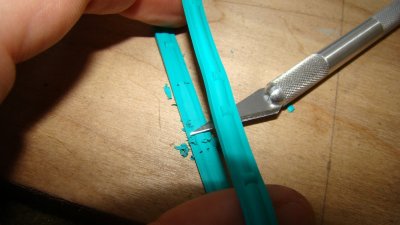

3) Mike further discussed ideas to modify the manifold. He suggested possibly welding the grooves, razoring the surface and cutting new grooves. I will admit this is an interesting suggestion since it would allow me to further port the manifold but it still leaves a lot of room for things to go wrong...and then who is left footing the bill for the new manifold and all the work I have put into it? Not worth the risk IMO.

So now that I have mentioned a cash option and no sooner than I left the Livernois shop and merged onto the highyway I got an email from Mike. Now let me predicate this by stating I am not one to post the contents of a PM but this goes to the credibility of Dan Millen. In summation, Mike said he had spoke too soon and that after relaying our conversation to Dan, Dan told Mike that the ports on my cylinder heads and a few other select customers were created especially by Dan for us customers.

This obviously raise several concerns and additional questions. If this was in fact created for my application, then why was my manifold not used to check alignment and sealing? Livernois certainly had possession of my car long enough. Why was this information not presented during the January 31, 2012 phone call? Timing of this new information is certainly suspect to say the least. If this oversized port was used intentionally and it has now been showed to be problematic then why isnt Livernois replacing them instead of looking to blame the manifold?

Sorry for the long post...