Whiskey11

SCCA Autoscrosser #23 STU

- Joined

- Feb 24, 2012

- Posts

- 1,644

- Reaction score

- 2

I wanted to have a discussion on Poly bushings in control arms for SCCA autocross in ESP and STX/STU (Eventually). For those outside the SCCA, the problem is that the SCCA does not allow the lower control arms to be replaced with anything. The bushing rules for ST are:

A few problems to consider there:

First: We can't run anything resembling a Delrin spherical bearing since we have to still accommodate articulation via compliance of the bushing.

Second: We can't increase the metal to non-metal ratio.

I think the second is going to be hard to protest, and a wheenie protest at that but I suppose it is protestable. As it stands right now, I can only find one company that produces a poly bushing for the stock lower control arms and that is Prothane. The kit # is 6-313. From the design of the kit it would appear to be a mistake to run it in unmodified form for autocross duty so I have two ideas for how to "fix" that problem but I'd like some input from people here with more specific knowledge on suspension bushing design.

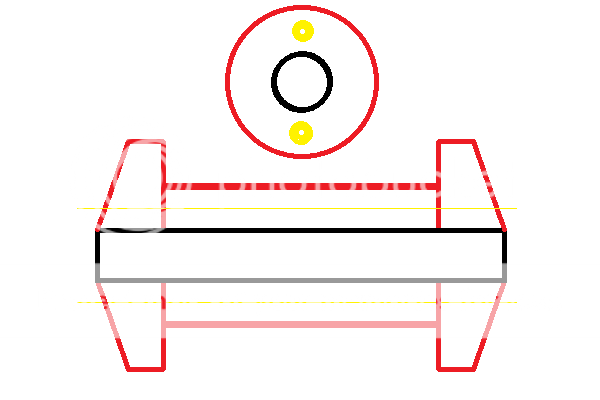

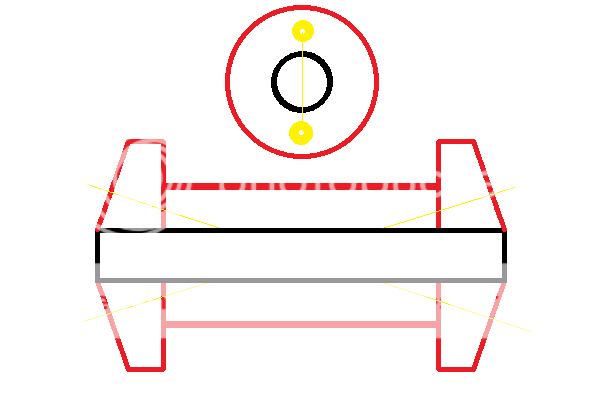

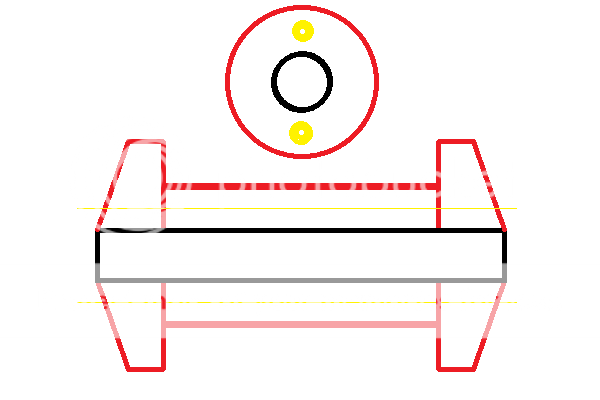

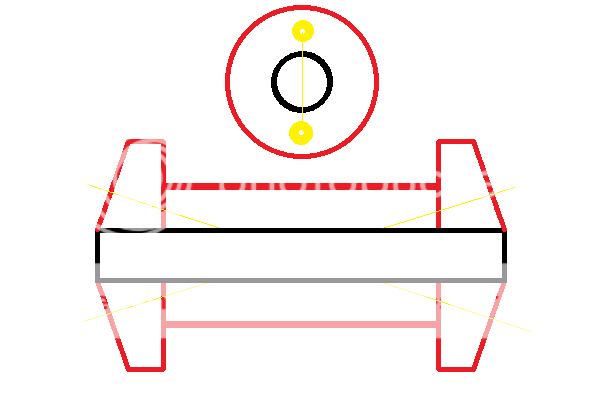

Here are my thoughts on the modified bushing (yellow lines indicate holes drilled in the bushing):

Idea 1 is the easiest to implement and should allow for some articulation in the vertical plane (axle articulation) but there will be some bind associated with it. Idea 2 would have a different effect on bushing bind, and I think it might reduce it over the first design.

The only other thought I had would be to make a 3 piece bushing, the center being the highest durometer, the outers being a lower durometer with cutouts similar to the factory bushings meaning holes through the outer two parts of the bushing in the upper and lower portions (where they are on the ideas above) to allow it to articulate more free while retaining the fore/aft stiffness necessary to combat bushing wheel hop and longitudinal location of the axle.

The reason I ask is because the Torque Arm I plan on purchasing (well any torque arm) is going to be removing a longitudinal locating part of the suspension (the UCA) and that presents itself with the added problem of keeping the axle centered in the fender wells with the stock control arms.

Anyone have any better thoughts that are SCCA legal?

B. Suspension bushings may be replaced with bushings of any materials (except metal) as long as they fit in the original location. Offset bushings may be used. In a replacement bushing, the amount of metal relative to the amount of non-metallic material may not be increased. This does not authorize a change in type of bushing (e.g., ball and socket replacing a cylindrical bushing) or use of a bushing with an angled hole whose direction differs from that of the original bushing. If the Stock bushing accommodated multi-axis motion via compliance of the component material(s), the replacement bushing may not be changed to accommodate such motion via a change in bushing type, for example to a spherical bearing or similar component involving internal moving parts. Pins or keys may be used to prevent the rotation of alternate bushings but may serve no other purpose than that of retaining the bushing in the desired position.

A few problems to consider there:

First: We can't run anything resembling a Delrin spherical bearing since we have to still accommodate articulation via compliance of the bushing.

Second: We can't increase the metal to non-metal ratio.

I think the second is going to be hard to protest, and a wheenie protest at that but I suppose it is protestable. As it stands right now, I can only find one company that produces a poly bushing for the stock lower control arms and that is Prothane. The kit # is 6-313. From the design of the kit it would appear to be a mistake to run it in unmodified form for autocross duty so I have two ideas for how to "fix" that problem but I'd like some input from people here with more specific knowledge on suspension bushing design.

Here are my thoughts on the modified bushing (yellow lines indicate holes drilled in the bushing):

Idea 1 is the easiest to implement and should allow for some articulation in the vertical plane (axle articulation) but there will be some bind associated with it. Idea 2 would have a different effect on bushing bind, and I think it might reduce it over the first design.

The only other thought I had would be to make a 3 piece bushing, the center being the highest durometer, the outers being a lower durometer with cutouts similar to the factory bushings meaning holes through the outer two parts of the bushing in the upper and lower portions (where they are on the ideas above) to allow it to articulate more free while retaining the fore/aft stiffness necessary to combat bushing wheel hop and longitudinal location of the axle.

The reason I ask is because the Torque Arm I plan on purchasing (well any torque arm) is going to be removing a longitudinal locating part of the suspension (the UCA) and that presents itself with the added problem of keeping the axle centered in the fender wells with the stock control arms.

Anyone have any better thoughts that are SCCA legal?