I installed BMR rear lower control arm relocation brackets over the holiday break and the install went relatively smooth. I have Steeda Sport springs installed so roughly 1.25" drop in the rear. I placed the lower control arm in the uppermost position in the new brackets and this gives about a 1/2" of drop from the front to the rear or the control arm. My question is around the axle position. The install shifted the axle rearward 1/8". It still looks fine in regards to being centered in the opening. I do have adjustable lower control arms. Should I bring the axle forward the 1/8" or leave it be? Any concerns or things to watch out for?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lower control arm relocation bracket install

- Thread starter fusion66

- Start date

Norm Peterson

corner barstool sitter

Might want to bring it back forward for pinion angle reasons. If so, maybe by a little more than 1/8" if the bushings in your LCAs are poly or anything else that's harder than the OE rubber bushings.

Norm

Norm

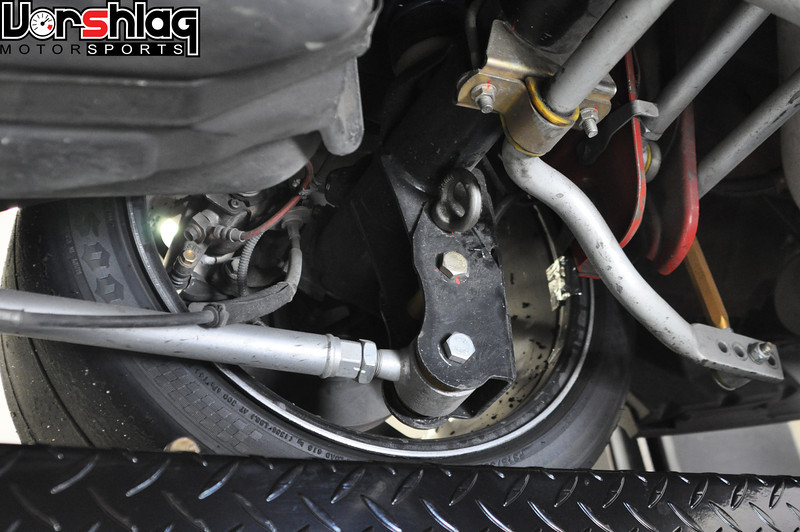

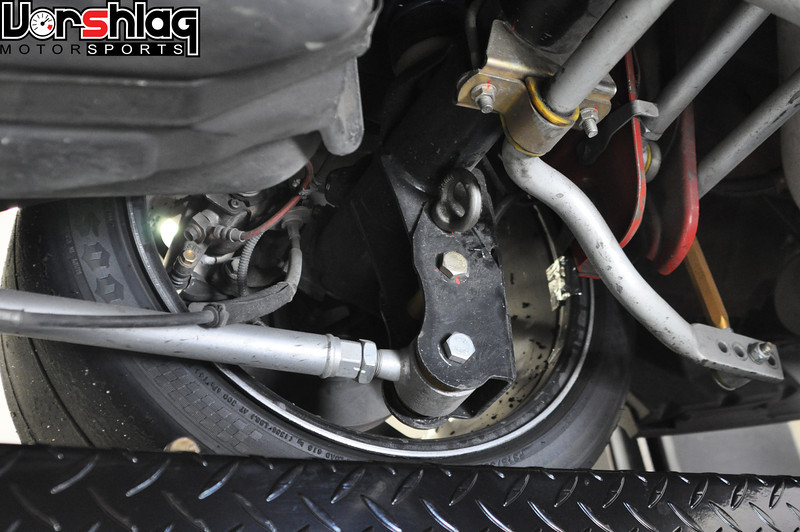

I used the same BMR LCA relocate brackets ( + BMR HD box type fixed LCA's with poly on each end) on my 2010. I didn't measure any shift rearward on the axle. That was with Roush lowering springs on the rear, and also roush monotube rear shocks. Roush claimed 1.25" rear drop. I started off in the uppermost holes.... but after 12 months, shifted to the middle holes..where they still remain. Better traction when the light goes green. Like Norm sez, since you have adjustable length LCA's, shorten them a tiny bit, and put the axle back to original location. Just make sure both lca's are tweaked to aprx equal length, so the axle ends up being perpendicular to the car's center line axis.

After lowering, don't be surprised if the axle sticks out on the driver's side by 3/8". My fix for that was the BMR on car adjustable PHB..and mating BMR PHB brace. Then it's a snap to center the back end of the car over the axle. Just crawl underneath....and tweak..with the help of a 2nd person.

https://www.bmrsuspension.com/?page=products&productid=172&superpro=0

Adjustable portion is made from chromolly steel..and goes on Pass side.

https://www.bmrsuspension.com/?page=products&productid=173&superpro=0

This item makes the oem version look like spaghetti.

I got em both in red.... my method of color coding stuff underneath.

After lowering, don't be surprised if the axle sticks out on the driver's side by 3/8". My fix for that was the BMR on car adjustable PHB..and mating BMR PHB brace. Then it's a snap to center the back end of the car over the axle. Just crawl underneath....and tweak..with the help of a 2nd person.

https://www.bmrsuspension.com/?page=products&productid=172&superpro=0

Adjustable portion is made from chromolly steel..and goes on Pass side.

https://www.bmrsuspension.com/?page=products&productid=173&superpro=0

This item makes the oem version look like spaghetti.

I got em both in red.... my method of color coding stuff underneath.

Last edited:

Norm Peterson

corner barstool sitter

The reason I suggested "just a bit more" than your 1/8" is because firmer LCA bushings don't require quite as much pinion angle as the OE rubber bushings.

Norm

Norm

Don't know how fussy you guys are about alignment, but to me it is very important. A few things you might want to consider if you have adjustable RLCAs and PHBs:

1. In relation to bushing type/material, us a protractor when setting pinion angle.

2. When "centering" the rear axle with an adjustable PHB, is it for looks or alignment. For alignment, measure off the frame rails.

3. Even better yet, "center" the rear axle while the car is on the alignment rack using the data.

4. Additionally, while on the alignment rack, use the data to micro-adjust the RLCA lengths.

5. Using the data, you'll be amazed at how square you can get the car and how close to zero you can get the thrust angle.

1. In relation to bushing type/material, us a protractor when setting pinion angle.

2. When "centering" the rear axle with an adjustable PHB, is it for looks or alignment. For alignment, measure off the frame rails.

3. Even better yet, "center" the rear axle while the car is on the alignment rack using the data.

4. Additionally, while on the alignment rack, use the data to micro-adjust the RLCA lengths.

5. Using the data, you'll be amazed at how square you can get the car and how close to zero you can get the thrust angle.

Couple of pointers based on the good advice from above...

Centering the axle (after lowering this is needed - with an adj panhard or watts link) is a cosmetic thing, to be sure, but an "offset axle" can also lead to tire rub if you have some meaty rear rubber.

1. To center the axle on an S197 the car needs to be at ride height (this can be simulated on a lift with the rear springs removed and the axle compressed to ride height). Tape strings at the center of both real wheel arches, then hang a "plumb bob" from each, to make them drop straight down. That's the fender indicator for both sides. Now measure inboard from the strings to the sidewall or rim face on the rear tires. When these two numbers measure the same (at ride height), the axle is centered.

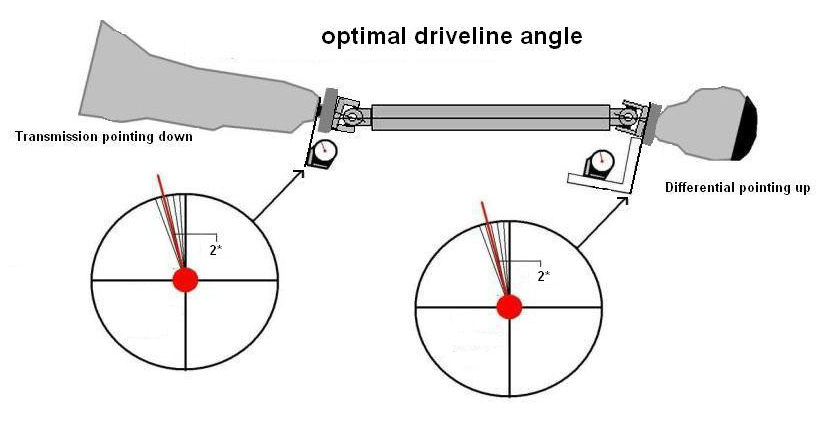

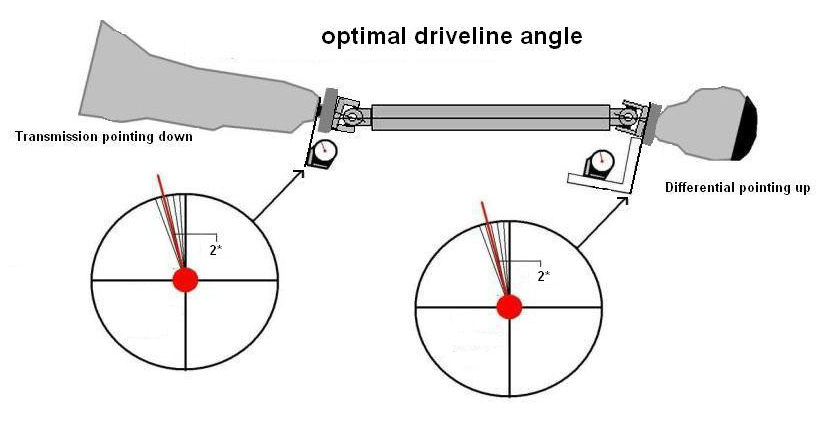

2. I think the previous poster meant to say "use a digital angle finder" (not protractor) when he explained how to measure pinion angle. Adjust your lower control arm lengths (and/or upper arm length, if you have an adjustable upper) to get the pinion angle you want. Ideally the angle of the transmission output flange is the same (but opposite) of the angle at the axle input flange, at ride height. Usually it is about 2 or 3 degrees, from memory.

This "optional driveline angle" theory works for a 1-piece driveshaft, but gets a little muddy for the (OEM) 2-piece driveshafts a lot of modern cars have.

Cheers,

Centering the axle (after lowering this is needed - with an adj panhard or watts link) is a cosmetic thing, to be sure, but an "offset axle" can also lead to tire rub if you have some meaty rear rubber.

1. To center the axle on an S197 the car needs to be at ride height (this can be simulated on a lift with the rear springs removed and the axle compressed to ride height). Tape strings at the center of both real wheel arches, then hang a "plumb bob" from each, to make them drop straight down. That's the fender indicator for both sides. Now measure inboard from the strings to the sidewall or rim face on the rear tires. When these two numbers measure the same (at ride height), the axle is centered.

2. I think the previous poster meant to say "use a digital angle finder" (not protractor) when he explained how to measure pinion angle. Adjust your lower control arm lengths (and/or upper arm length, if you have an adjustable upper) to get the pinion angle you want. Ideally the angle of the transmission output flange is the same (but opposite) of the angle at the axle input flange, at ride height. Usually it is about 2 or 3 degrees, from memory.

This "optional driveline angle" theory works for a 1-piece driveshaft, but gets a little muddy for the (OEM) 2-piece driveshafts a lot of modern cars have.

Cheers,

Similar threads

- Replies

- 1

- Views

- 639

- Replies

- 5

- Views

- 198

- Replies

- 5

- Views

- 1K

Support us!

Support Us - Become A Supporting Member Today!

Click Here For Details