Wes06

forum member

- Joined

- Jan 21, 2012

- Posts

- 5,383

- Reaction score

- 59

the time has come, come to drop the stang as low as possible, and still make speed bumps my bitch

Got started on my air kit, even though I had to start late because of other shit coming up late. then had to finish early due to it getting late

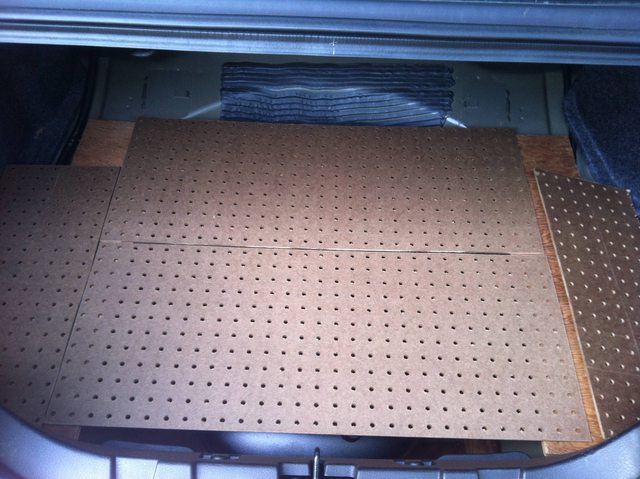

Pics of the stuff

only got to working on the mount for the air tank/compressor/control unit

only thing is the spare tire mount is in the way, im gonna cut open a square in the board and maybe even use it to help anchor everyone down too.

friend is gonna help me polish off the trunk mount tomorrow and work on my false floor, then run lines and air hoses.

Got started on my air kit, even though I had to start late because of other shit coming up late. then had to finish early due to it getting late

Pics of the stuff

only got to working on the mount for the air tank/compressor/control unit

only thing is the spare tire mount is in the way, im gonna cut open a square in the board and maybe even use it to help anchor everyone down too.

friend is gonna help me polish off the trunk mount tomorrow and work on my false floor, then run lines and air hoses.