Since I was sick and I had no energy to try and pull out the main caps, the first thing I did was get to work on the oil pump. After removing all the screws for the oil pump I opened her up hoping to find it shattered or cracked but as usual I was let down here. Here is what it looked like when I opened it up.

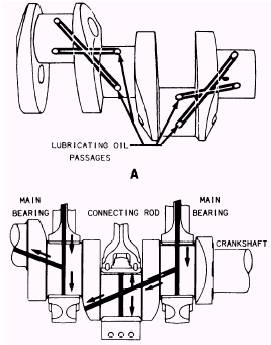

After taking a good look at it I didn’t see any cracks or anything like that but I did notice what we now know is bearing material on the inner and outer gears of the oil pump. I don’t see any scratches, cracks, gouges, brakes etc. in the oil pump gears so they should be good even though they will be being replaced in the build with a set of TSS gears.

Once I gained my strength back I decided to finish off tearing the block down to nothing, so I got to work on pulling the last 2 caps out. #4 came out fairly smooth (about 5 minutes of back and forth while pulling up at the same time) while #5 was decidedly more stubborn. In all honesty I felt like blowing it out with some C4 since it seemed to be coming out 1/16th of an inch every 4 minutes. After quite some time and wrestling, out it came and I was able to take a look at the crank. I didn’t notice any odd or unusual marks outside of what appears to be some marks from when the crankshaft was balanced so I didn’t take any pictures. But if you guys want pictures of my shaft you will have to get in line.

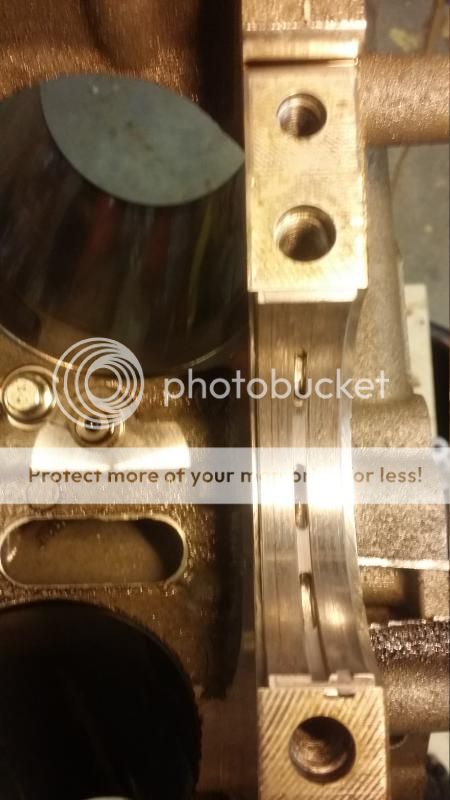

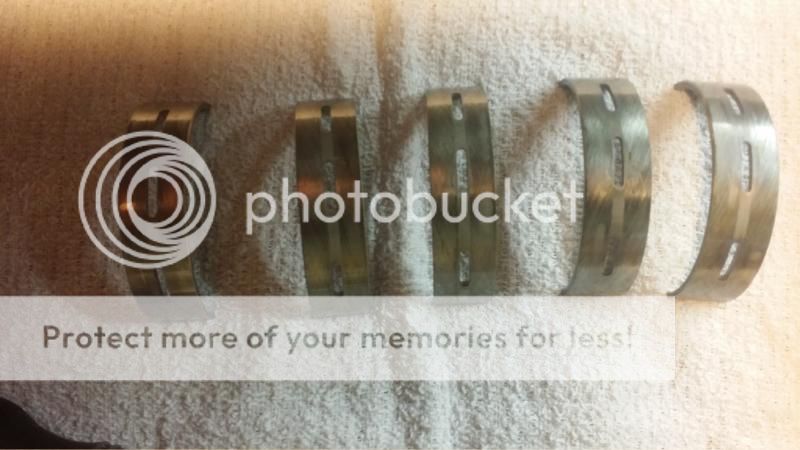

Anyway, I pulled out the bearings and from the top they looked decent, some minor scoring on them but the bottom side looked like there were some wear marks on them.

I tried to get a picture of all of them together to save some space but you can see for yourself. #3 & #4 both had the part numbers wiped out from them and it looks like the little tab was being worn down as well. All of the caps had these weird spots on the bottom that were completely smooth as opposed to this criss-cross pattern that seems to be made that way. If you look at the overhead view you can somewhat make out what I am talking about especially looking at the right hand side of the #3 bearing (order goes left to right so #1 on the far left and #5 on the far right).

Can anyone tell me if this is normal? It looks like there is some sort of scoring on the #5 main (I guess that is what you would call it).

Outside of that the block is completely torn down with nothing left on it. Now we are going onto the cleaning phase. I think that the internal side of cleaning will be taken care of when it comes time to machine the block as well put the liners in it but I will find out for sure when I get the quote from JPC.

- Oil Pump – 8 x T30

- Rear Main Seal Plate 6 x 10mm