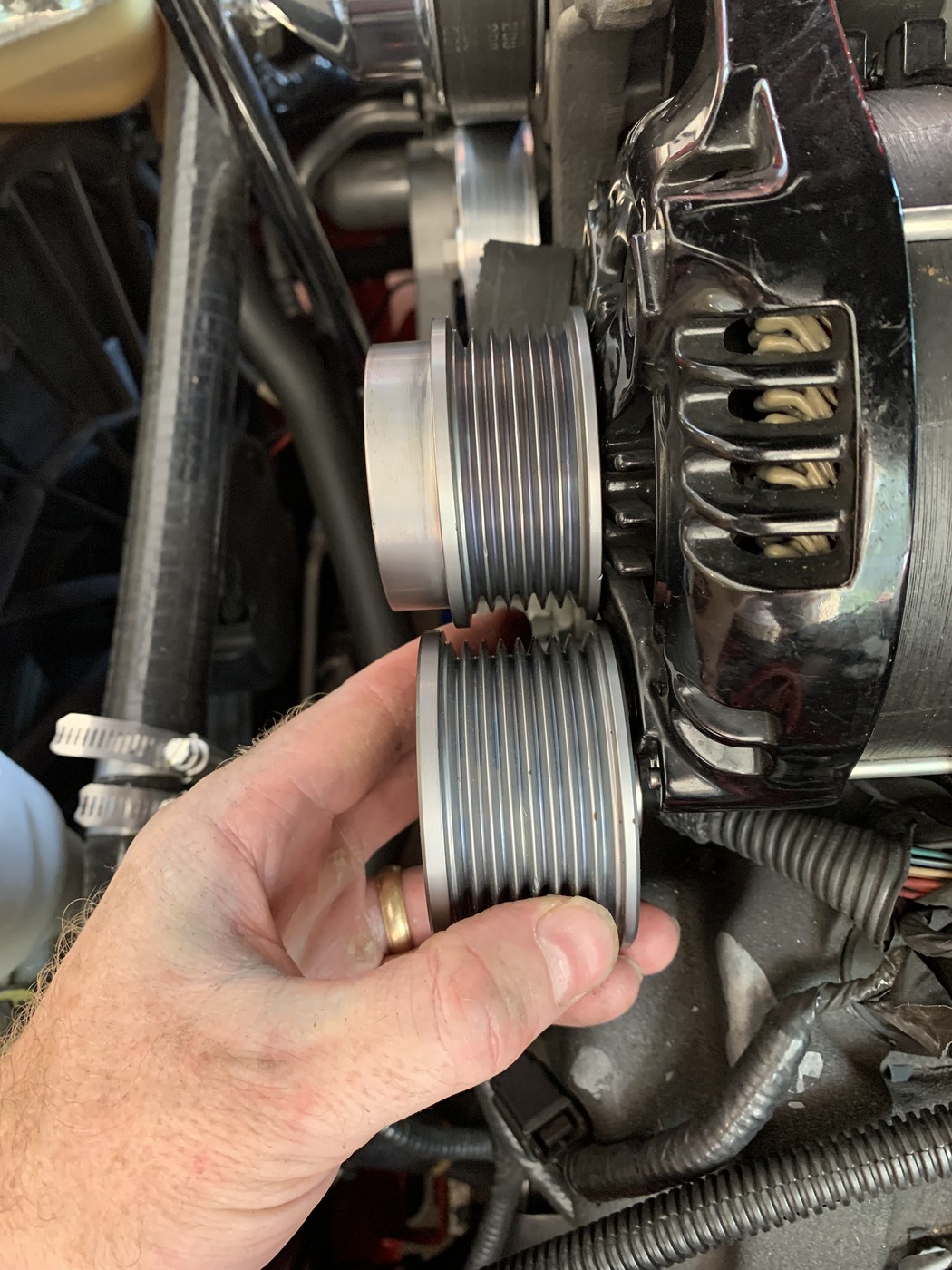

Because the rapid RPM change during gear shifts can cause belt issues. They are called "OAD" pulleys (Overrunning Alternator Decoupling).

I think on an automatic you could run one - or not - but they are mandatory with a manual.

From manufacturer WAI describing this design:

"The Overrunning Alternator Decoupler (OAD) has an internal one-way clutch that incorporates a torsion spring designed to absorb the base engine vibrations before reaching the alternator’s rotor. With the installation of an OAD, you will notice less tensioner motion, reduced NVH (noise, vibration and harshness) plus an all around robust accessory drive. This will allow the use of a narrower belt with lower output tensioner that will result in longer life of the alternator, water pump and other accessories’ bearings.

Other benefits are:

• Belt: Stabilization of belt vibrations, Reduced force level on the belt

•Tensioning system: Reduced tensioning force and travel on tensioner

• Increased service life on belt and tensioner system

• Alternator : Reduced load on alternator bearings • Rotor is uncoupled

• System : Extended system life , Improved noise reduction and vibration dampening, Reduced idle speed to improve fuel economy"