I get many questions about our current A-Arm offering for the S197 Mustang.

Earlier today, I decided to grab a single unit straight off the jig, and compare it to a piece that we built about 2-years ago. Of course, the Red one pictured from two years ago, does have newer revisions....was the only "built" piece here that I had to compare. I was able to grab the old style (thickness) gussets, to throw in with the pics.

We have had a few failures along the way with these pieces, and we have spent countless time, money, and effort to ensure they will provide the user with the best performing, and reliable welded tubular A-Arm on the market. Many have tried, and failed. We have continued to make improvements as needed, and are extremely proud and confident with our current design. For those reading, we ship over 300 sets of S197 each and every year, since 2006 - just to give you a rough idea of how many our out on the road, and tracks as I make this post.

To the pictures:

Uncoated Current Version on top, older style, Red, on bottom:

Old Style Gusset, note the drastic "sharp" change in direction/transition...as well as the hole on the right. (We no longer have any holes in our gussets, btw)

The current style....note the smooth transition, and no holes of course. (More on the "transition" later)

Current Gusset Thickness

Previous Gusset Thickness

Current "Center" Gusset Thickness

Previous "Center" Gusset Thickness

Another look at the outer gussets, comparing the transition differences

These are not "new" changes that we just now implemented. They are changes that occurred quite some time ago.

A few things that caused us issues with our gussets were having the "BMR" Logo cut out of the center gusset, as well as having that sharp transition on the outer gusset, as pictured above. We changed those gusset characteristics, as well as increased the thickness - just to be safe. As you upgrade one area, the weakest are fails next - it's a chain reaction, and we can tell you first hand all about it!

Since these were our problematic areas, I do not mind showing some pictures that I have, to inform you - and help understand the reason for the changes.

Here is a VERY old set. We only offered the Red Poly (instead of the Delrin) on the rear, for several months after offering these. These had, as you can see from the pictures, some serious use and weather applied to them. That is not an excuse, but they held up surprisingly well for 6 years.

This photo shows a crack started form the BMR Logo...weakened the center gusset, then causing unplanned force to the "transition" area I spoke about above. This is a perfect one shot says all, in terms of a chain reaction/domino effect.

Another shot, showing the start of the crack at the BMR...then the opposite side gusset cracking afterwards, at the "transition". This car proceeded to road course on these, for a few more races before receiving a newer version from us

This picture shows why we removed the holes/revised the outer gussets. This as an extreme-duty course car, used for R&D - and much testing.

So there you have it.

The majority of issues with BMR A-Arms have been due to improperly designed gussets, of which we changed/addressed years ago. Once a gusset is compromised...well, you can only imagine that the rest of the entire Arm is at great risk of encountering forces it was never intended to experience and withstand.

That said, we STILL run the older, really old version of our A-Arms on our personal/shop owned S197. We race it on the strip, and daily drive it....and drive it across the country. We do not believe they are "bad" - if so, we wouldnt be running them!

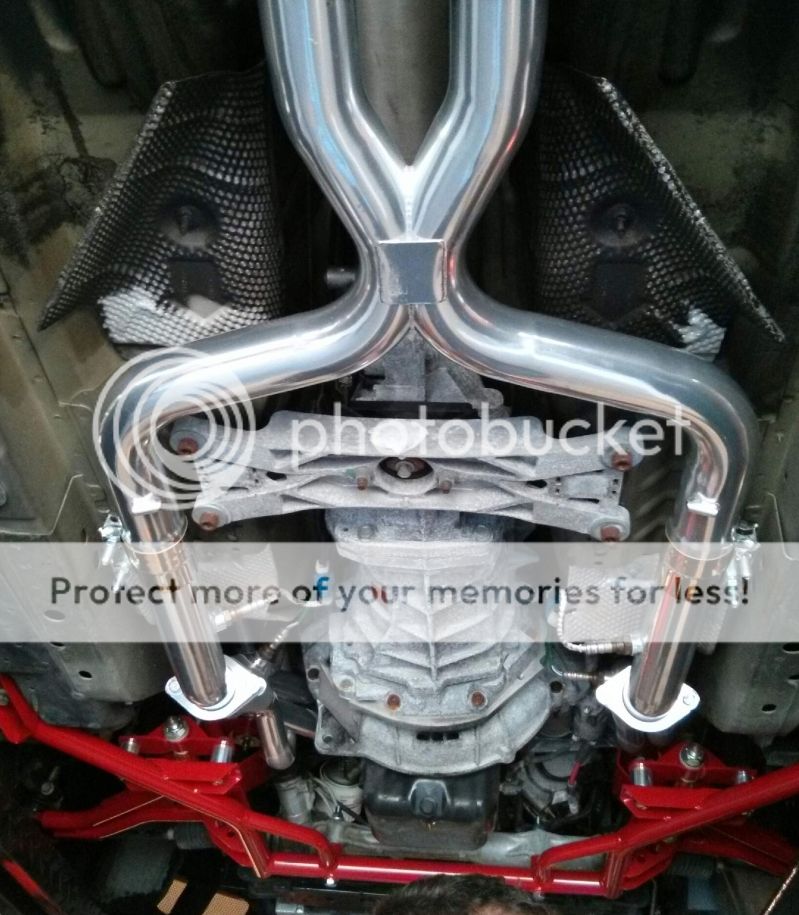

Here is proof, as our car was just on the lift. These are prototypes that we developed in mid 2010, to test fitment on the newer 2011+ cars. We modified a 2005-2009 Spec Arm, that we had laying around from about 2008/2009 ERA......and we are still rocking them, with confidence

*The majority of the small amount of failures that we have seen, were on road-course cars. We wanted to improve these items as time goes, in order to ensure that the road-course racers can have more confidence in our product. I've got some fairly serious course cars running these arms this year, and I await their feedback as time goes.

For customers looking to road-course on our arms, I highly suggest that they call me to discuss. There are several extremely important points that I like to make, as well as recommendations to prevent unwanted/planned damage or failure to the vehicle.

To end, here are photos of a customer who stopped his 3800lb GT500 with his passenger side tire/wheel, that was connected directly to our A-Arm....from over 80MPH. (Totaled the car after it flipped)

I'd say these BMR Pieces handled this impact better than a factory arm. Check out the BMR designed/specific Ball Joints too! People snap OEM Ball Joints in corners...I cannot imagine what would have happened to one in this scenario. Lastly, check out that bend on that Ball Joint cup! To bend that specific size steel in that fashion, is insane, to say the least.

The internet, unfortunately, shows the negative occurrences.

What it doesn't show you, is the many people who call me personally to thank me for making such a strong part. The Terry Nelsens, Miki Cohens who hit the wall at about 100MPH on the course, totaling everything except the BMR Components....the guy in the 3800lb Shelby that has our A-Arm prevent the car from smashing into a power pole at 80MPH, by having our A-Arm stop the car and flip it.....the Cobra Jet that does a 6ft wheelie, and proceeds to destroy the steering rack, struts, strut towers, spindles, but not the BMR K/Arms. The owners of body shops across the world, also don't post about the cars they repair that feature the BMR Front components when impact occurs. I will say, we have a lot of accounts now with body-shops...simply because they enjoy installing our parts, and believe they are better than OEM. (I wouldnt go that far - honestly...lol) It also won't show you, how serious we take the negatives....and do our best to ensure they do not occur again.

If you have any questions about our components, I am a phone call away.

Thanks for looking.

Earlier today, I decided to grab a single unit straight off the jig, and compare it to a piece that we built about 2-years ago. Of course, the Red one pictured from two years ago, does have newer revisions....was the only "built" piece here that I had to compare. I was able to grab the old style (thickness) gussets, to throw in with the pics.

We have had a few failures along the way with these pieces, and we have spent countless time, money, and effort to ensure they will provide the user with the best performing, and reliable welded tubular A-Arm on the market. Many have tried, and failed. We have continued to make improvements as needed, and are extremely proud and confident with our current design. For those reading, we ship over 300 sets of S197 each and every year, since 2006 - just to give you a rough idea of how many our out on the road, and tracks as I make this post.

To the pictures:

Uncoated Current Version on top, older style, Red, on bottom:

Old Style Gusset, note the drastic "sharp" change in direction/transition...as well as the hole on the right. (We no longer have any holes in our gussets, btw)

The current style....note the smooth transition, and no holes of course. (More on the "transition" later)

Current Gusset Thickness

Previous Gusset Thickness

Current "Center" Gusset Thickness

Previous "Center" Gusset Thickness

Another look at the outer gussets, comparing the transition differences

These are not "new" changes that we just now implemented. They are changes that occurred quite some time ago.

A few things that caused us issues with our gussets were having the "BMR" Logo cut out of the center gusset, as well as having that sharp transition on the outer gusset, as pictured above. We changed those gusset characteristics, as well as increased the thickness - just to be safe. As you upgrade one area, the weakest are fails next - it's a chain reaction, and we can tell you first hand all about it!

Since these were our problematic areas, I do not mind showing some pictures that I have, to inform you - and help understand the reason for the changes.

Here is a VERY old set. We only offered the Red Poly (instead of the Delrin) on the rear, for several months after offering these. These had, as you can see from the pictures, some serious use and weather applied to them. That is not an excuse, but they held up surprisingly well for 6 years.

This photo shows a crack started form the BMR Logo...weakened the center gusset, then causing unplanned force to the "transition" area I spoke about above. This is a perfect one shot says all, in terms of a chain reaction/domino effect.

Another shot, showing the start of the crack at the BMR...then the opposite side gusset cracking afterwards, at the "transition". This car proceeded to road course on these, for a few more races before receiving a newer version from us

This picture shows why we removed the holes/revised the outer gussets. This as an extreme-duty course car, used for R&D - and much testing.

So there you have it.

The majority of issues with BMR A-Arms have been due to improperly designed gussets, of which we changed/addressed years ago. Once a gusset is compromised...well, you can only imagine that the rest of the entire Arm is at great risk of encountering forces it was never intended to experience and withstand.

That said, we STILL run the older, really old version of our A-Arms on our personal/shop owned S197. We race it on the strip, and daily drive it....and drive it across the country. We do not believe they are "bad" - if so, we wouldnt be running them!

Here is proof, as our car was just on the lift. These are prototypes that we developed in mid 2010, to test fitment on the newer 2011+ cars. We modified a 2005-2009 Spec Arm, that we had laying around from about 2008/2009 ERA......and we are still rocking them, with confidence

*The majority of the small amount of failures that we have seen, were on road-course cars. We wanted to improve these items as time goes, in order to ensure that the road-course racers can have more confidence in our product. I've got some fairly serious course cars running these arms this year, and I await their feedback as time goes.

For customers looking to road-course on our arms, I highly suggest that they call me to discuss. There are several extremely important points that I like to make, as well as recommendations to prevent unwanted/planned damage or failure to the vehicle.

To end, here are photos of a customer who stopped his 3800lb GT500 with his passenger side tire/wheel, that was connected directly to our A-Arm....from over 80MPH. (Totaled the car after it flipped)

I'd say these BMR Pieces handled this impact better than a factory arm. Check out the BMR designed/specific Ball Joints too! People snap OEM Ball Joints in corners...I cannot imagine what would have happened to one in this scenario. Lastly, check out that bend on that Ball Joint cup! To bend that specific size steel in that fashion, is insane, to say the least.

The internet, unfortunately, shows the negative occurrences.

What it doesn't show you, is the many people who call me personally to thank me for making such a strong part. The Terry Nelsens, Miki Cohens who hit the wall at about 100MPH on the course, totaling everything except the BMR Components....the guy in the 3800lb Shelby that has our A-Arm prevent the car from smashing into a power pole at 80MPH, by having our A-Arm stop the car and flip it.....the Cobra Jet that does a 6ft wheelie, and proceeds to destroy the steering rack, struts, strut towers, spindles, but not the BMR K/Arms. The owners of body shops across the world, also don't post about the cars they repair that feature the BMR Front components when impact occurs. I will say, we have a lot of accounts now with body-shops...simply because they enjoy installing our parts, and believe they are better than OEM. (I wouldnt go that far - honestly...lol) It also won't show you, how serious we take the negatives....and do our best to ensure they do not occur again.

If you have any questions about our components, I am a phone call away.

Thanks for looking.