Hi there, I know this topic has been discussed previously on some of the various forums but I haven't quite been able to find the exact information I need.

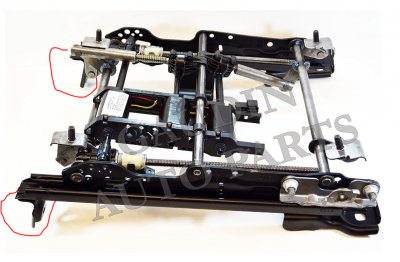

I am 6'11'' and in order to fit in the s197 I need to be able to position the seat as far back and as low down as possible (further than stock). Are any of you aware of any existing brackets that would achieve such a purpose, or do you know of anyone who has made modifications to their seat rails that would result in this extra space?

I called this Mustang shop in the LA area to ask if they could do it, but they said it would involve 'a lot of fabrication and engineering with the airbag sensors etc.' They estimated $1-2k for the job. Needless to say, I am a bit skeptical as to the airbag sensor story and price tag.

I'd really like to get one so any suggestions would be highly appreciated.

Thanks

I am 6'11'' and in order to fit in the s197 I need to be able to position the seat as far back and as low down as possible (further than stock). Are any of you aware of any existing brackets that would achieve such a purpose, or do you know of anyone who has made modifications to their seat rails that would result in this extra space?

I called this Mustang shop in the LA area to ask if they could do it, but they said it would involve 'a lot of fabrication and engineering with the airbag sensors etc.' They estimated $1-2k for the job. Needless to say, I am a bit skeptical as to the airbag sensor story and price tag.

I'd really like to get one so any suggestions would be highly appreciated.

Thanks

. That's a great suggestion regarding the drag racing shops! I'm not too far from Pomona Raceway so there must be a bunch of them around over there. Thanks for the input.

. That's a great suggestion regarding the drag racing shops! I'm not too far from Pomona Raceway so there must be a bunch of them around over there. Thanks for the input.