An aluminium driveshaft will drop those numbers by ~1%

FYI......................all the dyno runs\sheet results of my car were made w\ a Ford Performance Aluminum 1-Piece Driveshaft installed........so going by your given numbers for driveline parasitic loss this really makes a 1-piece aluminum driveshaft usage vs the OEM 2-piece driveshaft design as far as

rotational acceleration parasitic loss goes a statistical wash as the OEM 2-piece's driveline tube dia's are smaller than the Ford 1-piece aluminum driveshaft's tube dia (front section dia is 3" vs 3 1\2", rear section is 2 1/2" vs 3 1\2")......basic physics concerning rotational parasitic loss vs where the mass is located in relation to the C\L of rotation (or distance away from the C\L). The closer the mass is to C\L lowers the rolling moment of the part around its axis........meaning the

smaller dia is generally easier to move initially. Mass has much less of an effect in this instance..........where the mass does have an effect is in inertial momentum......meaning the

deceleration capabilities of the 1-piece aluminum driveshaft vs the OEM 2-piece driveshaft once both are spun up to speed.

This aspect of physics has been proven numerous times.................

I inadvertently tested this out by accident using my car set up\leveled on jackstands w\ rear axle on the jackstands, so the rear suspension was loaded so DL angles were set when I was chasing down the rear gear issues from the 1st initial install of the Richmond EXCEL 3.90 (3.89 actual 9 pinion\35 ring) gears before I swapped them out for the Motive Gear F888390 (3.91 actual 11 pinion\43 ring) gears. I had the Ford Performance 1-piece aluminum driveshaft installed & when I put the trans in 5th gear w\ engine at idle speeds, I noticed that the ECU had some trouble maintaining the engine idle speed steady\smooth after initial clutch engagement occurred......engine idle had a very noticeable up\down cadence in its idle speed control......meaning the engine was reacting to\chasing the aluminum driveshaft's rolling moment\inertial momentum characteristics. When I pulled this driveshaft out afterwards, installed the Ford OEM 2-piece driveshaft & w\ the car set up in the exact same position, ran it in the same 5th gear under same idle, the ECU quickly leveled out the engine after initial clutch engagement occurred & maintained a noticeably smoother\steadier idle speed cadence w\ very, very little change\oscillations.........meaning the engine was reacting to the OEM 2-piece driveshaft's rolling moment\inertial momentum characteristics as both driveshafts had the exact same loads\resistance exerted on both thru the rear axle gearing & suspension components\geometry angles, tire weights & same rolling moment\inertial momentum exerted from the tires\rotors\axles\gearing along w\ any rear brake caliper pad drag.......so the only items that were in actual differing affects to the engine's idle control was the 2 driveshaft's design characteristics..........neither driveshaft caused the engine to bog down noticeably lower than the other in RPMs off initial clutch engagement thus the rolling moments of the 2 driveshafts were essentially the same, but 1 driveshaft's mass had a noticeable effect on inertial momentum once both were spun up to idle RPMs......the OEM 2-piece driveshaft was the clear winner (or loser depending on POV) here & is a major reason why Ford OEM 2-piece driveshafts are much smoother\less prone to driveline vibrations\NVH transfer in operation as long as the other components in the 2-piece driveshaft (CV joints, center carrier bearing\hanger & front U-joint) are in good condition. From real world driving comparison for me afterwards, the difference was very obvious.............is the main reason why the Ford OEM 2-piece driveshaft is still installed under my Stang to this day (cruiser duty is my #1 priority) & the Ford Performance 1-Piece Aluminum Driveshaft is still sitting in my shed to be used as a spare.

Now if I were to get into HPDE circuit track racing seriously........................be a different conversation as in this type of environment,

every advantage has merit, regardless of how large or small.

Where an aluminum drive shaft is also superior is due to the

total measured mass\weight of the part vs the OEM 2-piece driveshaft.......

thus the total overall weight\mass of the vehicle it is installed in vs the same vehicle w\ the OEM 2-piece driveshaft installed.......there is no question of its "superiority" in this instance, regardless of how the car is being used.

Remember, when the OEM 2-piece driveshaft is hung under the car, its

total mass has no bearing on the rotational aspects of this driveshaft as most ALL of its total mass is supported by

the chassis thru the center support bracket\bearing, w\ the rest suspended by the rear axle pinion & trans output shafts on roller bearings..........thus not in play to the engine's rotational TQ output........thus rolling moment.

This aspect\fact is very often left out of the discussion & not touched on\acknowledged.........................

Again, basic Mechanical Engineering 101.............but Marketing Strategies 101 along w\ basic Capital Consumer Economics has sold a bunch of these aluminum driveshafts...........myself included as I own 1................

So as far as driveshafts are concerned IMHO when talking dynos, this isn't a difference maker as dynos don't measure roller deceleration.......only roller acceleration.........so only falls within the margins at best........too many other, more viable variables exist to counter a driveshaft design whether OEM or aluminum.

This is why I put the word superiority in quotation marks............because variables do matter along w\ a person's POV & is the reason why dynos are always a hypothetical conversation\discussion........even in\with the best of intentions.

Of course, YMMV..............depending on your POV........

As far as getting my car dyno'd before the timing refresh\Hot Rod cam swapout, this may not happen as I definitely ain't going back to my local prior tuner & even remotely give him access to my car's OBDII port..........a good way to get my tune access locked out thru potential tuner retaliation using HPTuner's Tuner Lock feature (don't really know if he would do this or not....I can guarantee he can't if I don't go there & give him access) just to find out what she's putting down now peak to peak.............if I go to Albuquerque & get this done on a dyno that was different from the Mustang dyno used here locally, along w\ the elevation difference between the 2 areas (roughly 3,000') alone & the numbers came out higher or lower, I'll say it now that all this will be brought up at some time & point along w\ any other potential variable(s) that would\could make a difference.........during the discussion of the numbers.

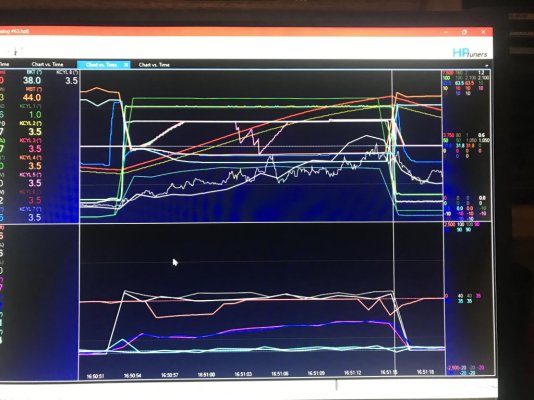

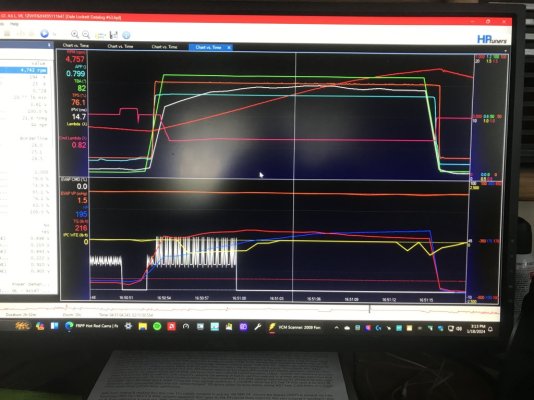

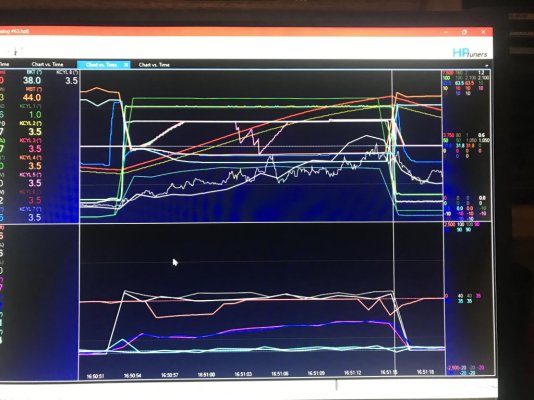

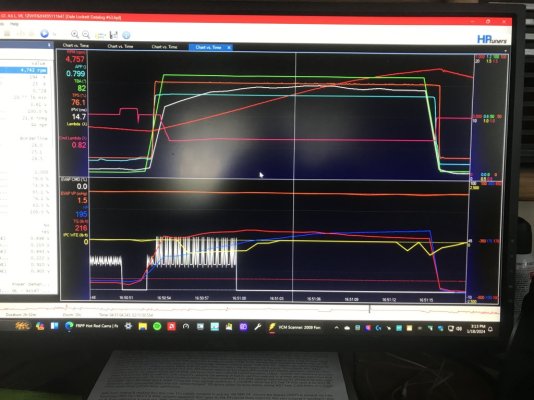

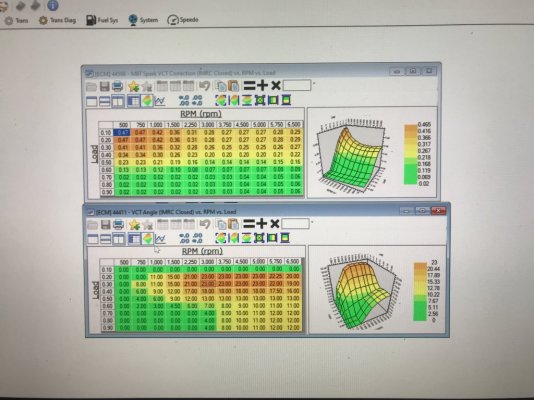

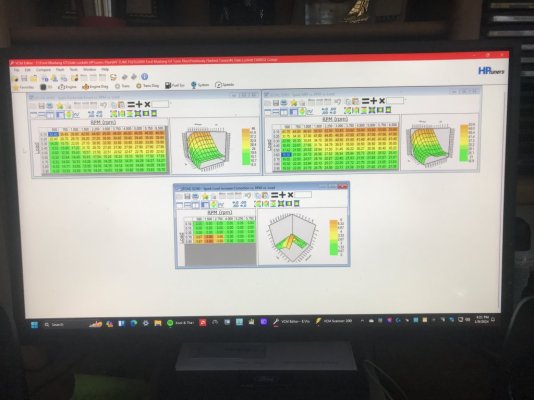

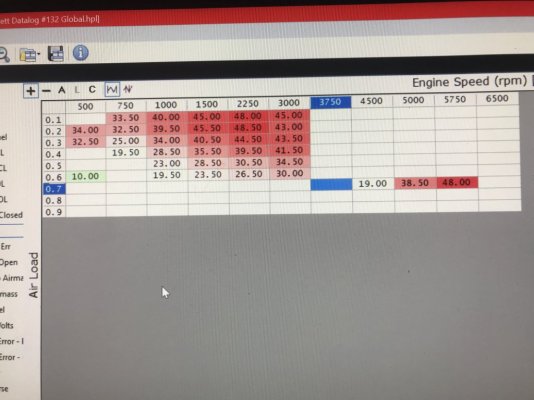

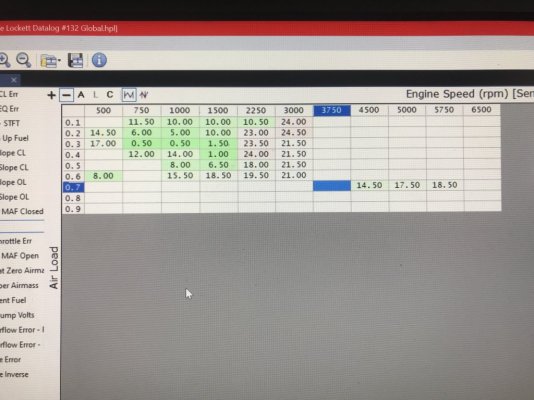

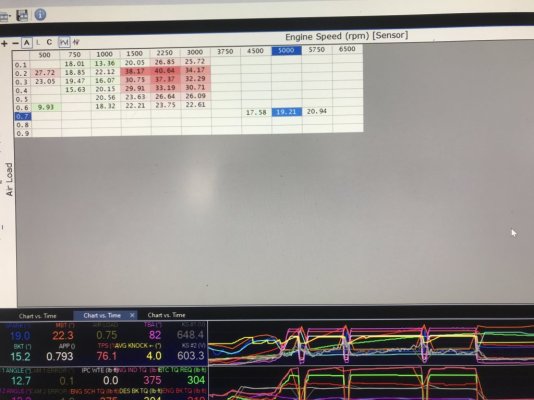

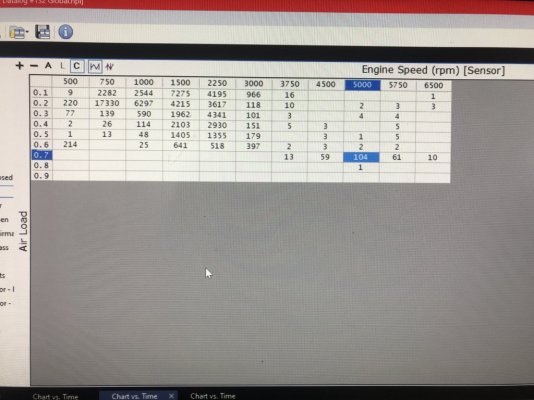

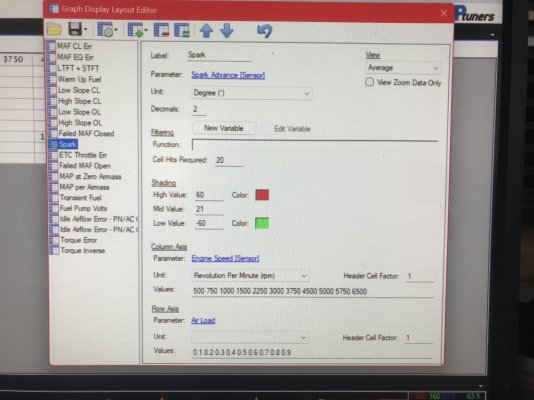

In times past, this would be of more importance to me to get a dyno run done & recorded, but since I now have HPTuners VCM Suite & MPVI2+ interface in hand & can actually see the calculated TQ outputs derived from my front-end tuning results (the EBTQ outputs are primarily calc'd off the accuracy of the upfront SD airmass tuning\calcs & back checked\corrected by MAF airmass tuning\calcs using the same fueling calcs\corrections & spark timing\VCT cam retard timing settings using the same trans gearing, rear gear ratio\tire size dia thus same NV calcs for driveline mechanical TQ (which the car's gross weight & any chassis drag coeff, tire rolling moments will affect) thru using the trans VSS RPMs output compared to the engine's RPMs output........the IPC Wheel TQ Error graphs showing me that the SD calcs are essentially in line w\ the MAF calcs so ALL tuning in my tune calibration is good\accurate enough to take the EBTQ outputs (mostly an engine flywheel centered calc that is based off real rear wheel characteristics......just not included in the EBTQ calcs) as a good indicator of what my car's capabilities are\will now do so I'm not nearly as interested in getting\paying for a dyno run\sheet now.......................only thing I need to do is to go out in Mexico & make a couple of 4th gear 2,500 rpm to limiter WOT hits to record it & finish it all up.........already have a "Dyno" math function set up in HPTuners VCM Scanner datalog charts that will use the ECU's calc'd EBTQ output data & calc the HP derived from it w\ 5,252 RPM cross point according to current engine RPMs so I can get the peak to peak TQ\HP output graph curves from this to serve my general purposes...........w\o paying anyone else.

Example provided below............................the red & blue graph traces in 2nd picture are "HP" & "TQ" from my VCM Scanner's "Dyno" math function. The mouse pointer line will give me the rest.........

I did this once early last year but didn't get to redline (was approx 320 RPM short......redline is set @ 6,500 on ETC as primary limiter w\ spark\fuel cut as secondary limiters to protect my timing chain guides, tensioners, phasers, OPG's & potential piston to valve clearance issues from any overrevs) due to me letting off throttle from my hood deflector shield pulling the plastic rivet clips out of the hood shield's metal mounting brackets & blowing over the car's roof at around 122 MPH at the time (3.91 gears\26.1" dia tires at 6,500 RPM redline 4th gear @ 130 MPH)........on less EBTQ output than now. The replacement hood deflector shield is now bolted to the mounting brackets using M8 x 16mm license plate bolts thru M8 windshield fairing nut clips using blue Loctite on bolt threads so she ain't coming off no more...............

So yes, she should get there a little faster now than it did then............this is where a Dragy would come in handy.........they're cheaper than a dyno session to boot...............modern technology put to good use.

Just being real about it all.