GlassTop09

Senior Member

Hi All,

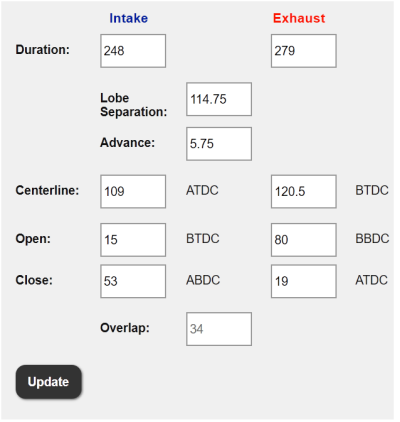

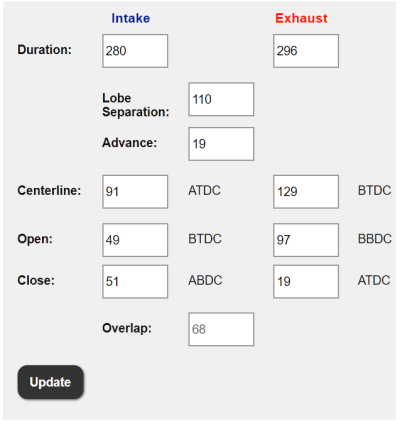

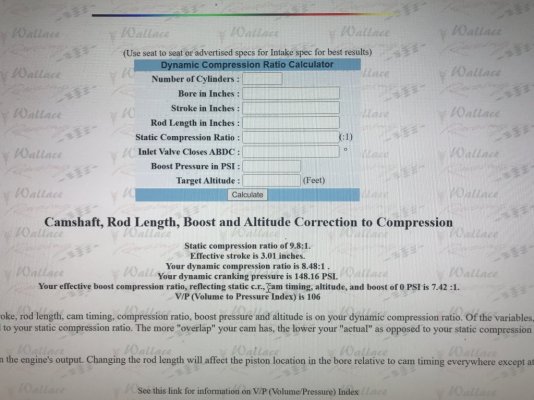

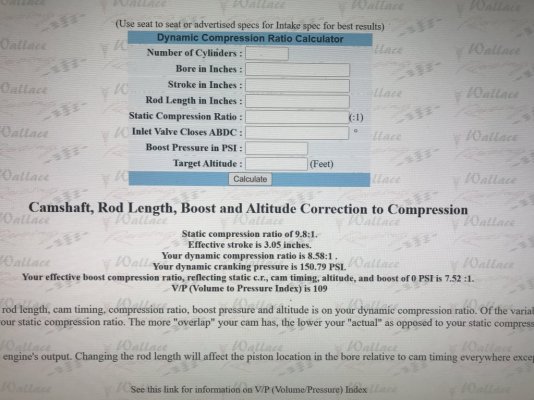

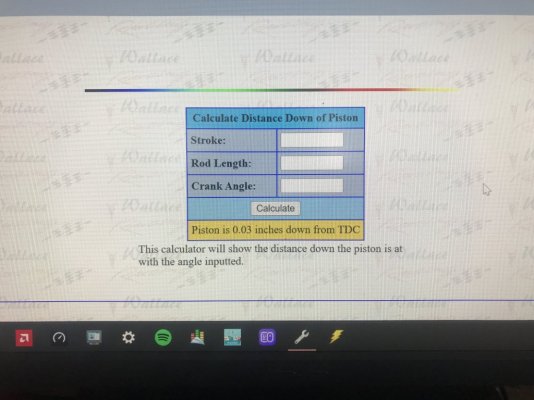

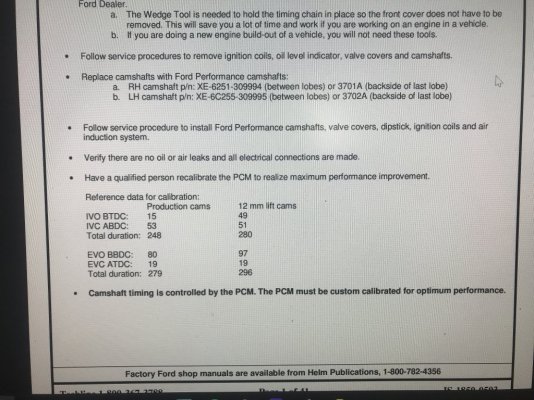

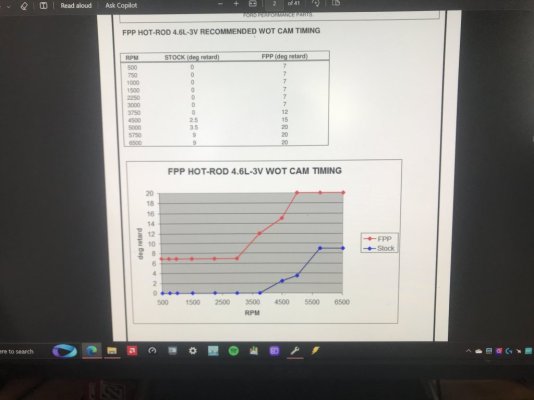

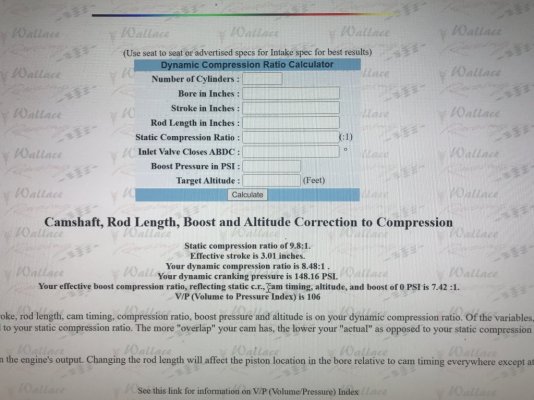

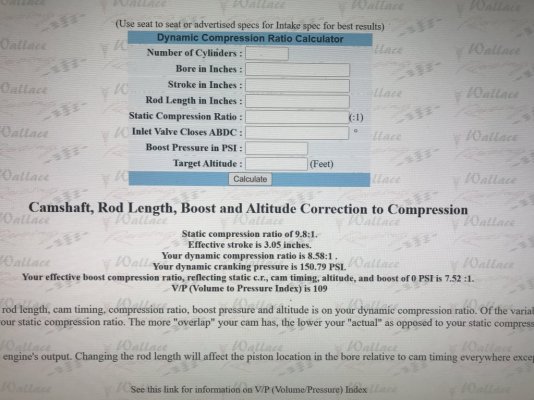

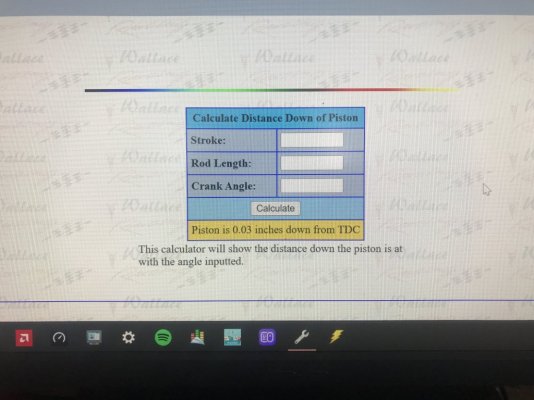

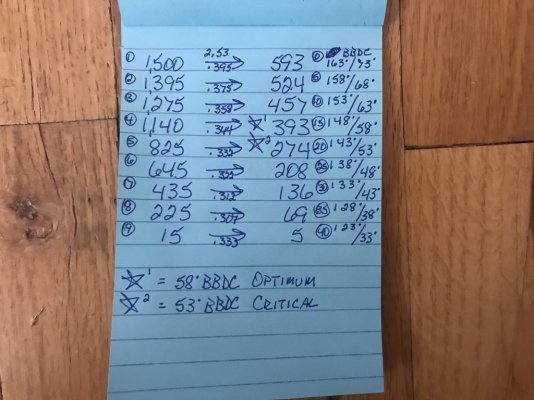

Just recently acquired a set of NIB FRPP Hot Rod cams for a song & have also acquired a set of FRPP Cam Phaser bolts so at some point in the near future I'll be swapping out & installing these cams in my 4.6L 3V V8 to get me some of that idle chop sound action but also to see just how much low end, mid-range & top end WOT HP\TQ--along w\ how much available HP\TQ across the board from off idle to redline--I can squeeze out of them using all the cam-to-crank correlation science I've laid out that I've used to tune my Lunati VooDoo #21270700 cams. Ford SVT engineers have given a lot of info thru the Hot Rod cam installation instructions sheet to use to optimize them using VCT & TM..........most are familiar w\ the recommended WOT VCT cam timing settings Ford provided......but how many also made note of the actual .006" adv dur cam timing point data Ford gave of these cams in comparison to the same .006" adv dur cam timing points data Ford gave of the OEM stock cams along w\ the extra valve lift height data & ran modeling of all this to get an idea of how to set up these Hot Rod cams to get the most available HP\TQ under the curve across the board as well as WOT peak HP\TQ? I can't answer this for others, but I can give some answers for myself as I did all this using Wallace Racing's various engine calculators to get an idea of what I'm looking at to determine the best VCT EVO cam timing mapping to set up to achieve max TQ leveraging application on the engine's cross plane crankshaft along with the optimum cam IVC point\VCT spark multi advance to optimize the dynamic cyl pressure curves to fully optimize this engine's meager displacement for max net TQ output from off idle thru redline.

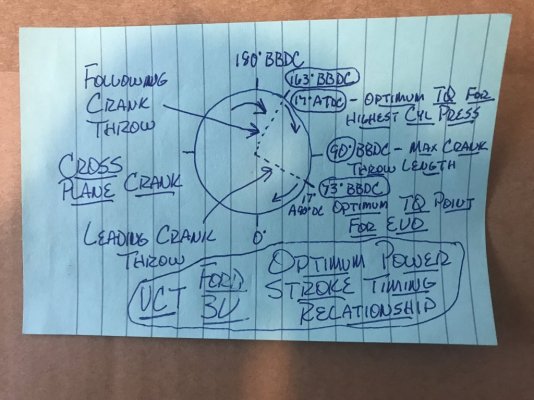

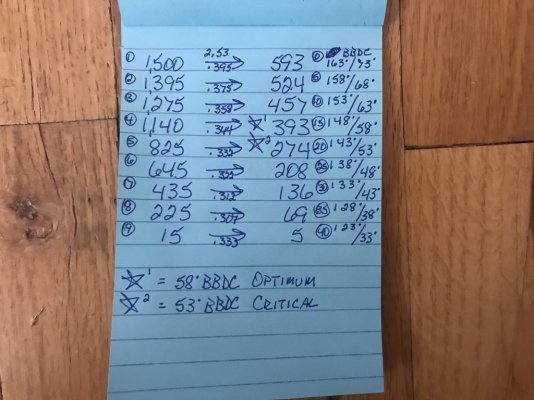

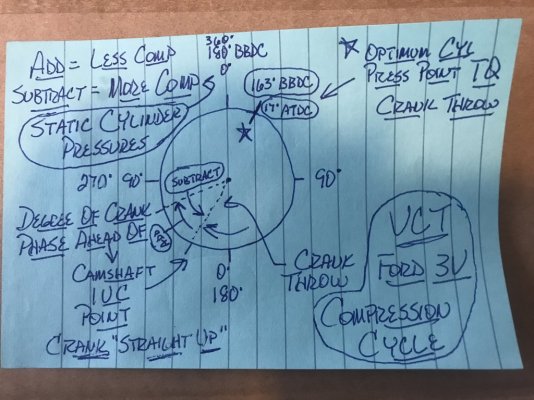

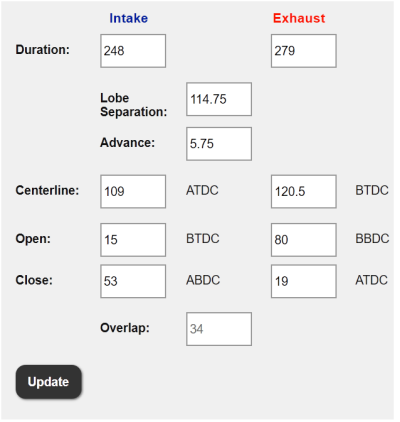

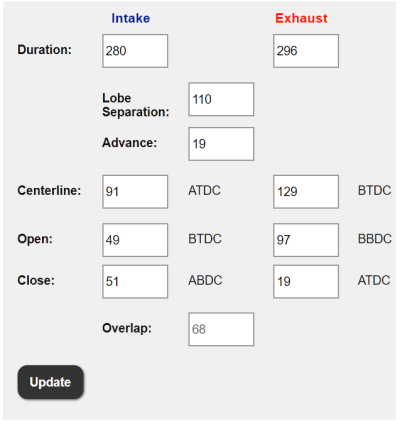

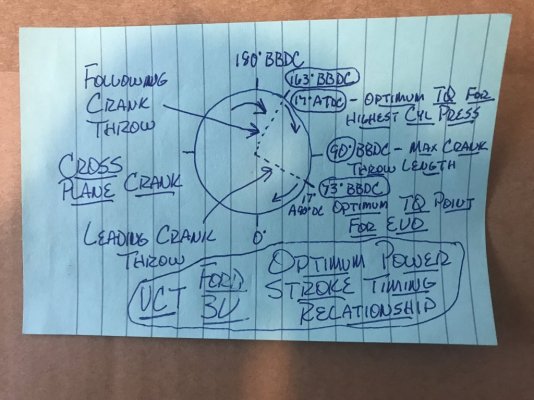

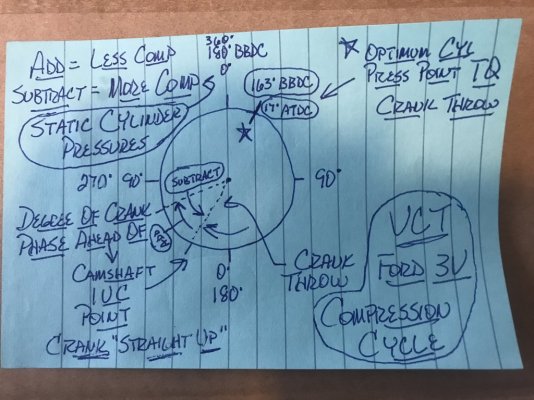

1st off, I found out that Ford used the 10* ATDC crank throw point to determine the TQ leveraging thru the crankshaft during the power stroke.....this matches up exactly w\ the OEM stock cams adv dur EVO timing point (80* BBDC) at VCT 0* cam timing (or "straight up" cam to crank timing) so the leading cyl in late power stroke position smoothly hands off TQ force application to the following cyl coming into early power stroke position--the 10* ATDC position--just as the leading cyl's EVO point is reached to start bleeding off cyl pressure thus entering the exhaust cycle so no spinning flywheel inertial momentum is needed thus all TQ force generated from cyls AND flywheel inertia is sent to drive the rear wheels. This is why the OEM stock cams can put out so much off idle, low RPM TQ output & is why Ford leaves these cams at VCT 0* cam timing until the engine RPM's exceed 1,000 RPMs. The Hot Rod cams same adv dur EVO timing point at VCT 0* cam timing is 97* BBDC or is opening a full 17* early thus the late power stroke leading cyl isn't taking full advantage of its full 90* crank throw length (losing TQ leverage force relative to the OEM stock cams at same VCT 0* timing point) as well as the early power stroke following cyl is still coming up to TDC during its compression stroke\ignition firing point thus also increasing pumping loss (counter force to actual power stroke cyl press pushing piston down thus causes some more net TQ loss) so engine spinning flywheel inertial momentum is needed to continue the crankshaft rotation to get the early power stroke following cyl into the optimum 10* ATDC position w\ max cyl pressure exertion on piston so now the early power stroke following cyl can start to exert its TQ force onto its crank throw to now start regaining twisting force to rear wheels AND to reload the spinning flywheel of its lost inertial momentum to be used on the next cyl exchange (which also will net some more TQ loss)......IF the OEM VCT cam timing mapping used to optimize the OEM stock cams is left intact as Ford initially set this up in tune calibration.

This is a fact that is killing FRPP Hot Rod cams (most other aftermarket cams as well for that matter......tested & found this to be true using my Lunati VooDoo cams) ability to make good low end TQ & so many tuners make the mistake of leaving this in-tune VCT cam timing mapping at stock settings......then wonder why these Hot Rod cams show to lose low end TQ output vs the OEM stock cams......even though at the same VCT 0* cam timing point, the Hot Rod cams actually DO have a dynamic compression advantage (earlier cam IVC timing point.....HR @ 51* ABDC vs OEM @ 53* ABDC) vs the OEM stock cams thus can put out more dynamic cyl pressure during compression stroke\ignition firing but due to this engine's small bore size, this dynamic cyl pressure advantage of the Hot Rod cams isn't near enough to begin to counter the massive TQ leveraging losses during the power stroke when these Hot Rod cams are left at the same VCT 0* cam timing point as the OEM stock cams. Another hard fact that is getting missed.......all this data is right in front of anyone who is looking at the cam timing data that Ford has put on the Hot Rod cam installation sheet......all 1 needs to do is to model it & all this comes out.

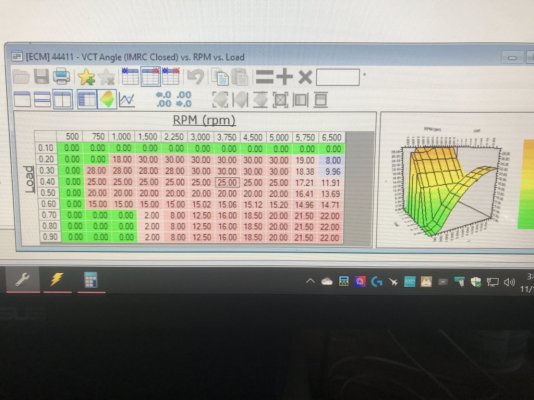

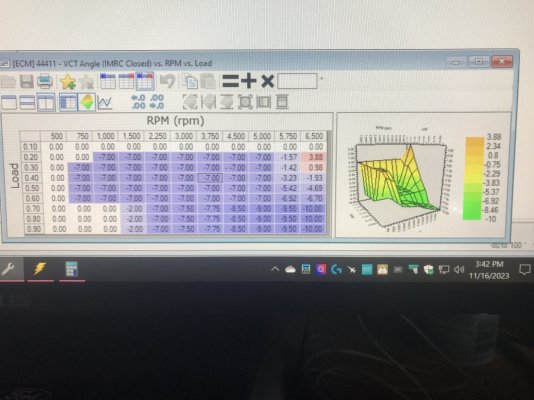

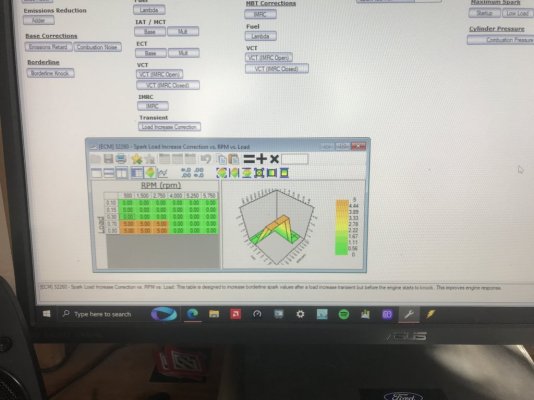

For the Hot Rod cams to have a fair shot at making good low end TQ output, the VCT cam timing needs to start retarding these cams ASAP off idle RPM's to get the cam EVO timing to line up to the crank throw at the 80* BBDC crank throw point......thus they need to be retarded at least 17* to bring the HR cam 97* EVO timing point to match up to the crank power stroke 80* BBDC timing point so the TQ leveraging is fully resolved by the time the engine RPMs leave 750 RPMs (idle) & reach 1,000 RPMs....the same 1,000 RPM point that the OEM cams are starting to be retarded from VCT 0* cam timing point for pumping loss gains\EGR flow for NOx reduction & any perceived MPG gains so now is negating the OEM stock cams TQ leveraging advantage. But now the HR cams have lost the dynamic compression advantage by retarding the cam adv dur IVC timing the same 17* vs the OEM stock cams still at VCT 0* cam timing.......this is why the Ford folks supplied the BKT\MBT Spark Advance VCT Multi Adder timing maps (that most tuners disable unfortunately by zeroing these maps out)......their sole existence is to supply a certain amount of additional spark advance correction timing as a multi to every degree of VCT EVO cam timing retard being used to counter the dynamic compression losses caused by VCT cam IVC retard to bring the dynamic compression back to VCT 0* cam timing scale to then allow the base BKT\base MBT spark advance timing to further apply spark timing to bring the operational cyl pressure back in line thus now the Hot Rod cams will have ALL the advantages swung to their favor as far as TQ output is concerned.....but then the HR cams have another advantage here that the OEM cams just can't compete with.....the induction advantage created by the HR cam's IVO thru EVC timing points....the OL along w\ the slightly higher valve lift creating better low lift head flow during the OL which, along w\ the early cam IVO timing point, will start the induction airmass flow moving much earlier using the better exhaust scavenging flow from the larger, longer OL to create higher induction air velocity entry into cyls which will cause a small "supercharging effect" thus packing more airmass into cyls also being aided by the later retarded cam IVC timing points so cyl have a much denser\cooler & optimally mixed\atomized A\F intake charge, better net dynamic compression gain thus higher cyl pressures at the 10* ATDC power stroke point AND now will get ALL the same TQ leveraging during the power stroke as the OEM stock cams did at VCT 0* cam timing, thus now the HR cams will "out TQ" the OEM cams from this point on out......IF the tuner will not use the stock VCT cam timing mapping as found but rearrange all this to the HR cams advantage (why I mapped the net cyl pressure of 2 cyls exerting their TQ force on crankshaft during same power stroke cycle to allow no more than 15* of crank rotation past the 10* ATDC point before opening the leading cyl cam EVO timing point to make max net TQ force......anything past this point is diminishing returns TQ wise but is losing exhaust gas velocity necessary to create good exhaust scavenging & is only good for reducing pumping losses for MPG purposes & for EGR purposes for NOx reduction.....but from my testing w\ my Lunati VooDoo cams, this extra cam EVO retard for EGR is not needed as there exists enough cam EVC retard at 32* max cam EVO retard (this is at the 15* max crank timing TQ point past the 10* ATDC timing point that uses 2 cyls TQ output during the same power stroke cycle) to sufficiently handle any NOx reduction thru EGR w\o negatively sacrificing net TQ output so there is no need to retard the cams any further than 32* max.

So all I'm doing is remapping the VCT cam retard mapping to correct the HR cams power stroke TQ leveraging to match\exceed the OEM stock cams from off idle low RPM TQ output on, use the BKT\MBT Spark Advance VCT Multi Adder Correction maps to regain the lost dynamic compression from retarded cam IVC timing thus now taking advantage of the HR cams better induction air charge cyl mixing\atomization & loading to then exceed the OEM stock cams TQ output even further & to maintain it from this point all the way to redline.

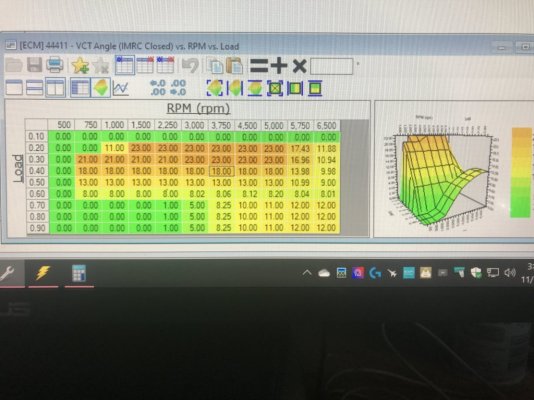

The only way to achieve this is to redo the Airload VCT load% cam retard timing map settings from the OEM stock setup so that all the new VCT cam retard settings favor the HR cams adv dur cam IVO, IVC, EVO, EVC, OL & fuel inj EOIT CA ref timings to make power from off idle to redline then follow up w\ the BKT\MBT Spark Advance VCT Multi Correction map settings to correct the retarded cam IVC timing to correct the dynamic compression back to the HR cams advantage to further make higher cyl pressures........then you should have a winning combination going.......sounds damn good chopping at idle but pulls like a freight train off idle onwards once VCT makes cam timing corrections to properly line up w\ the crankshaft's TQ leveraging capabilities.

If you now have any of the supporting components installed--such as a free-flowing induction charging system, LTH's & a FFE.......which I already have in place--to take further advantage of the induction cam timing by improving on the exhaust scavenging thus air intake charge loading, the FRPP Hot Rod cam HP\TQ output should only get better.

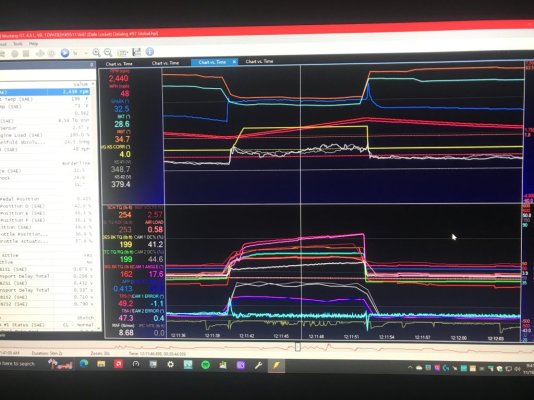

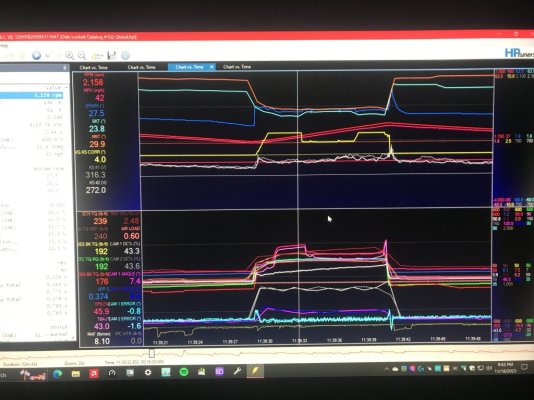

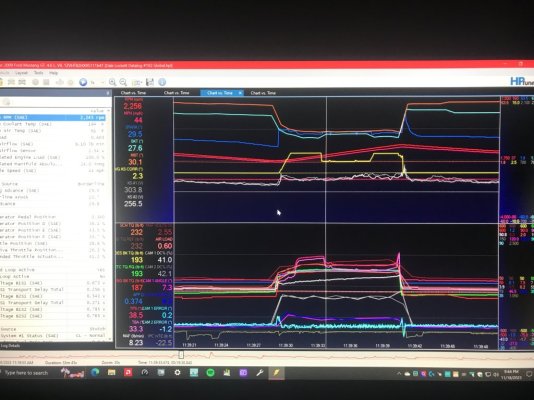

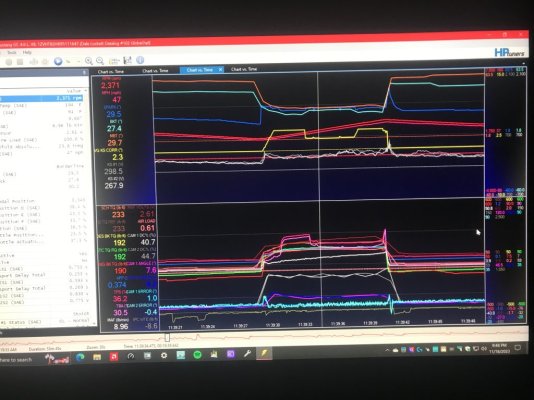

I've already witnessed this happening w\ my Lunati VooDoo cams on subsequent datalogs so only need to record this on a dyno sheet then do the Hot Rod cam swapout, redo the tune calibration to reflect all that I have typed here (BTW, the tune file is already done so waiting on cam swapout), optimize it using TM then record on dyno sheet. I'm figuring that the engine max WOT air load should exceed .80-.85 load (my Lunati's got to .77-.78 load max) from the Hot Rod's cam profile w\ slightly higher valve lift which should break 90% VE capacity @ 6,500 RPM redline by my estimation (my Lunati's got to 84% WOT VE around 6,184 RPMs in 4th gear before the bug shield blew off car hood & I backed out).

So, this should be attainable as currently configured w\o a lot of effort on my end.................

Only thing left to do is to do it & let the data speak for itself.

Posted for those so inclined...............

Just recently acquired a set of NIB FRPP Hot Rod cams for a song & have also acquired a set of FRPP Cam Phaser bolts so at some point in the near future I'll be swapping out & installing these cams in my 4.6L 3V V8 to get me some of that idle chop sound action but also to see just how much low end, mid-range & top end WOT HP\TQ--along w\ how much available HP\TQ across the board from off idle to redline--I can squeeze out of them using all the cam-to-crank correlation science I've laid out that I've used to tune my Lunati VooDoo #21270700 cams. Ford SVT engineers have given a lot of info thru the Hot Rod cam installation instructions sheet to use to optimize them using VCT & TM..........most are familiar w\ the recommended WOT VCT cam timing settings Ford provided......but how many also made note of the actual .006" adv dur cam timing point data Ford gave of these cams in comparison to the same .006" adv dur cam timing points data Ford gave of the OEM stock cams along w\ the extra valve lift height data & ran modeling of all this to get an idea of how to set up these Hot Rod cams to get the most available HP\TQ under the curve across the board as well as WOT peak HP\TQ? I can't answer this for others, but I can give some answers for myself as I did all this using Wallace Racing's various engine calculators to get an idea of what I'm looking at to determine the best VCT EVO cam timing mapping to set up to achieve max TQ leveraging application on the engine's cross plane crankshaft along with the optimum cam IVC point\VCT spark multi advance to optimize the dynamic cyl pressure curves to fully optimize this engine's meager displacement for max net TQ output from off idle thru redline.

1st off, I found out that Ford used the 10* ATDC crank throw point to determine the TQ leveraging thru the crankshaft during the power stroke.....this matches up exactly w\ the OEM stock cams adv dur EVO timing point (80* BBDC) at VCT 0* cam timing (or "straight up" cam to crank timing) so the leading cyl in late power stroke position smoothly hands off TQ force application to the following cyl coming into early power stroke position--the 10* ATDC position--just as the leading cyl's EVO point is reached to start bleeding off cyl pressure thus entering the exhaust cycle so no spinning flywheel inertial momentum is needed thus all TQ force generated from cyls AND flywheel inertia is sent to drive the rear wheels. This is why the OEM stock cams can put out so much off idle, low RPM TQ output & is why Ford leaves these cams at VCT 0* cam timing until the engine RPM's exceed 1,000 RPMs. The Hot Rod cams same adv dur EVO timing point at VCT 0* cam timing is 97* BBDC or is opening a full 17* early thus the late power stroke leading cyl isn't taking full advantage of its full 90* crank throw length (losing TQ leverage force relative to the OEM stock cams at same VCT 0* timing point) as well as the early power stroke following cyl is still coming up to TDC during its compression stroke\ignition firing point thus also increasing pumping loss (counter force to actual power stroke cyl press pushing piston down thus causes some more net TQ loss) so engine spinning flywheel inertial momentum is needed to continue the crankshaft rotation to get the early power stroke following cyl into the optimum 10* ATDC position w\ max cyl pressure exertion on piston so now the early power stroke following cyl can start to exert its TQ force onto its crank throw to now start regaining twisting force to rear wheels AND to reload the spinning flywheel of its lost inertial momentum to be used on the next cyl exchange (which also will net some more TQ loss)......IF the OEM VCT cam timing mapping used to optimize the OEM stock cams is left intact as Ford initially set this up in tune calibration.

This is a fact that is killing FRPP Hot Rod cams (most other aftermarket cams as well for that matter......tested & found this to be true using my Lunati VooDoo cams) ability to make good low end TQ & so many tuners make the mistake of leaving this in-tune VCT cam timing mapping at stock settings......then wonder why these Hot Rod cams show to lose low end TQ output vs the OEM stock cams......even though at the same VCT 0* cam timing point, the Hot Rod cams actually DO have a dynamic compression advantage (earlier cam IVC timing point.....HR @ 51* ABDC vs OEM @ 53* ABDC) vs the OEM stock cams thus can put out more dynamic cyl pressure during compression stroke\ignition firing but due to this engine's small bore size, this dynamic cyl pressure advantage of the Hot Rod cams isn't near enough to begin to counter the massive TQ leveraging losses during the power stroke when these Hot Rod cams are left at the same VCT 0* cam timing point as the OEM stock cams. Another hard fact that is getting missed.......all this data is right in front of anyone who is looking at the cam timing data that Ford has put on the Hot Rod cam installation sheet......all 1 needs to do is to model it & all this comes out.

For the Hot Rod cams to have a fair shot at making good low end TQ output, the VCT cam timing needs to start retarding these cams ASAP off idle RPM's to get the cam EVO timing to line up to the crank throw at the 80* BBDC crank throw point......thus they need to be retarded at least 17* to bring the HR cam 97* EVO timing point to match up to the crank power stroke 80* BBDC timing point so the TQ leveraging is fully resolved by the time the engine RPMs leave 750 RPMs (idle) & reach 1,000 RPMs....the same 1,000 RPM point that the OEM cams are starting to be retarded from VCT 0* cam timing point for pumping loss gains\EGR flow for NOx reduction & any perceived MPG gains so now is negating the OEM stock cams TQ leveraging advantage. But now the HR cams have lost the dynamic compression advantage by retarding the cam adv dur IVC timing the same 17* vs the OEM stock cams still at VCT 0* cam timing.......this is why the Ford folks supplied the BKT\MBT Spark Advance VCT Multi Adder timing maps (that most tuners disable unfortunately by zeroing these maps out)......their sole existence is to supply a certain amount of additional spark advance correction timing as a multi to every degree of VCT EVO cam timing retard being used to counter the dynamic compression losses caused by VCT cam IVC retard to bring the dynamic compression back to VCT 0* cam timing scale to then allow the base BKT\base MBT spark advance timing to further apply spark timing to bring the operational cyl pressure back in line thus now the Hot Rod cams will have ALL the advantages swung to their favor as far as TQ output is concerned.....but then the HR cams have another advantage here that the OEM cams just can't compete with.....the induction advantage created by the HR cam's IVO thru EVC timing points....the OL along w\ the slightly higher valve lift creating better low lift head flow during the OL which, along w\ the early cam IVO timing point, will start the induction airmass flow moving much earlier using the better exhaust scavenging flow from the larger, longer OL to create higher induction air velocity entry into cyls which will cause a small "supercharging effect" thus packing more airmass into cyls also being aided by the later retarded cam IVC timing points so cyl have a much denser\cooler & optimally mixed\atomized A\F intake charge, better net dynamic compression gain thus higher cyl pressures at the 10* ATDC power stroke point AND now will get ALL the same TQ leveraging during the power stroke as the OEM stock cams did at VCT 0* cam timing, thus now the HR cams will "out TQ" the OEM cams from this point on out......IF the tuner will not use the stock VCT cam timing mapping as found but rearrange all this to the HR cams advantage (why I mapped the net cyl pressure of 2 cyls exerting their TQ force on crankshaft during same power stroke cycle to allow no more than 15* of crank rotation past the 10* ATDC point before opening the leading cyl cam EVO timing point to make max net TQ force......anything past this point is diminishing returns TQ wise but is losing exhaust gas velocity necessary to create good exhaust scavenging & is only good for reducing pumping losses for MPG purposes & for EGR purposes for NOx reduction.....but from my testing w\ my Lunati VooDoo cams, this extra cam EVO retard for EGR is not needed as there exists enough cam EVC retard at 32* max cam EVO retard (this is at the 15* max crank timing TQ point past the 10* ATDC timing point that uses 2 cyls TQ output during the same power stroke cycle) to sufficiently handle any NOx reduction thru EGR w\o negatively sacrificing net TQ output so there is no need to retard the cams any further than 32* max.

So all I'm doing is remapping the VCT cam retard mapping to correct the HR cams power stroke TQ leveraging to match\exceed the OEM stock cams from off idle low RPM TQ output on, use the BKT\MBT Spark Advance VCT Multi Adder Correction maps to regain the lost dynamic compression from retarded cam IVC timing thus now taking advantage of the HR cams better induction air charge cyl mixing\atomization & loading to then exceed the OEM stock cams TQ output even further & to maintain it from this point all the way to redline.

The only way to achieve this is to redo the Airload VCT load% cam retard timing map settings from the OEM stock setup so that all the new VCT cam retard settings favor the HR cams adv dur cam IVO, IVC, EVO, EVC, OL & fuel inj EOIT CA ref timings to make power from off idle to redline then follow up w\ the BKT\MBT Spark Advance VCT Multi Correction map settings to correct the retarded cam IVC timing to correct the dynamic compression back to the HR cams advantage to further make higher cyl pressures........then you should have a winning combination going.......sounds damn good chopping at idle but pulls like a freight train off idle onwards once VCT makes cam timing corrections to properly line up w\ the crankshaft's TQ leveraging capabilities.

If you now have any of the supporting components installed--such as a free-flowing induction charging system, LTH's & a FFE.......which I already have in place--to take further advantage of the induction cam timing by improving on the exhaust scavenging thus air intake charge loading, the FRPP Hot Rod cam HP\TQ output should only get better.

I've already witnessed this happening w\ my Lunati VooDoo cams on subsequent datalogs so only need to record this on a dyno sheet then do the Hot Rod cam swapout, redo the tune calibration to reflect all that I have typed here (BTW, the tune file is already done so waiting on cam swapout), optimize it using TM then record on dyno sheet. I'm figuring that the engine max WOT air load should exceed .80-.85 load (my Lunati's got to .77-.78 load max) from the Hot Rod's cam profile w\ slightly higher valve lift which should break 90% VE capacity @ 6,500 RPM redline by my estimation (my Lunati's got to 84% WOT VE around 6,184 RPMs in 4th gear before the bug shield blew off car hood & I backed out).

So, this should be attainable as currently configured w\o a lot of effort on my end.................

Only thing left to do is to do it & let the data speak for itself.

Posted for those so inclined...............