I bought my 07 4.6L already modded. It has header back exhaust, ford racing throttle body, CAI, stiffened chassis. That’s what I have found so far.

At any rate, I know the factory horsepower on these is 300 hp. I found a Dyno test done on my car that showed 282 whp and 296 ft/lb torque. I assumed that was a pre-mod Dyno given the numbers.

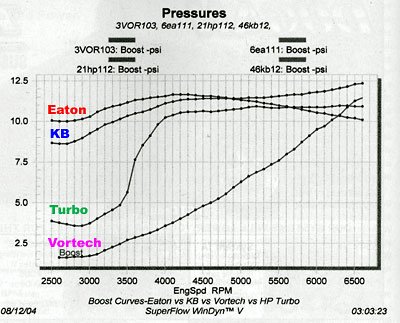

I hear a lot about supercharged 4.6s topping out at around 400 hp but have heard as much as 600. I have not done a Dyno on my car yet. Obviously a Dyno will tell me real numbers in my car which I intend to do.

But, I am wondering if maybe the Dyno that I know was done at 282 whp is actually post mod? But that doesn’t make sense given factory rating. I would expect post mod to be 330ish. For those who have modded, what has been your experience in pre and post mod hp?

Thanks

At any rate, I know the factory horsepower on these is 300 hp. I found a Dyno test done on my car that showed 282 whp and 296 ft/lb torque. I assumed that was a pre-mod Dyno given the numbers.

I hear a lot about supercharged 4.6s topping out at around 400 hp but have heard as much as 600. I have not done a Dyno on my car yet. Obviously a Dyno will tell me real numbers in my car which I intend to do.

But, I am wondering if maybe the Dyno that I know was done at 282 whp is actually post mod? But that doesn’t make sense given factory rating. I would expect post mod to be 330ish. For those who have modded, what has been your experience in pre and post mod hp?

Thanks