I think some folks are confusing swaybars with bolt-on chassis braces, subframe connectors, torque arms and other useless doo-dads. You can argue and calculate and quote Carroll Smith and postulate online but that still doesn't change the fact that modern cars function better with swaybars at both ends. Just like they function better with dampers on each corner, tires on each corner, and brakes on each corner. They aren't magic, but they are necessary.

There's always going to be less-than-perfect suspension advice out there, but we have to all be vigilant to keep from falling into the trap of "that sounds so easy and cheap that it must work!". Like disconnecting ABS systems, or thinking that there's a cheap way to make your brakes bulletproof, or that you can get great handling with Chinese coilovers, or that those scrub race tires you got for cheap are as good as new race tires.

NO.

Carroll Smith was a great race car driver, engineer, and author. He died 13 years ago. I've read all of his books cover to cover, and much of it still holds true, but most of his experience and writing had to do with small, lightweight, formula cars. And even those still have swaybars. He was not infallible, and some of his theories have since been replaced with better data. Again, on the whole his writing is excellent and insightful, but it is starting to become a bit dated. 4 of his 6 "...To Win" racing books were written in the 1970s-1980s, and a LOT of automotive technology has changed since then. The advances in tire technology alone since the 1980s is revolutionary, not to mention ABS systems, EFI systems, cylinder head design, damper design, and more.

I'm not trying to disparage folks form NOT reading his 6 books - you should buy them and read them, they are still very helpful - but you have to realize that much of his race car building career was in the 1960s GT40 program and into the 1970s with formula cars. An S197 Mustang has little in common with those when it comes to finite details like "running without a rear swaybar".

Seriously, don't try to remove your swaybar at either end of your S197 Mustang. It will turn your big, heavy, stick axle unibody cars into a big hot mess. You are welcome to test this, but again, most of the "internet testing" I've seen regarding running no swaybars is so poorly done and inaccurate that these outlier data points can be chalked up to internet folklore.

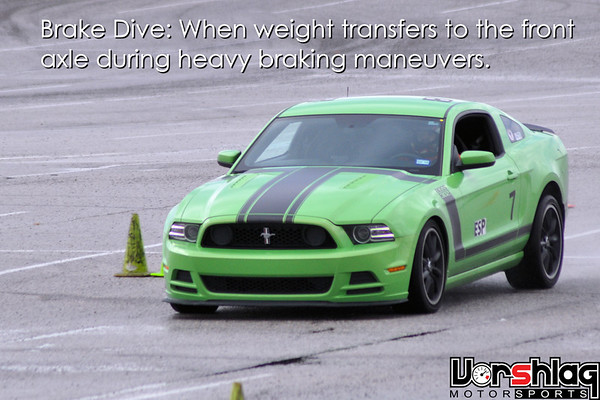

There is some solid conventional wisdom surrounding swaybars - use them as a tuning tool and to help with transitional movement in the car, but not as a crutch for lack of spring rate. I see so many people discussing swaybars that still have OEM lowering springs on their cars. Those are too soft to even test with. Coilover springs are usually 300-500% stiffer than OEM springs, because that is what keeps are car from moving too far in roll, dive, or heave. If you don't even have proper monotube dampers, you aren't even in the ball park of good handling and you should stop trying to "overthink" shortcuts to proper suspension setup like removing swaybars.

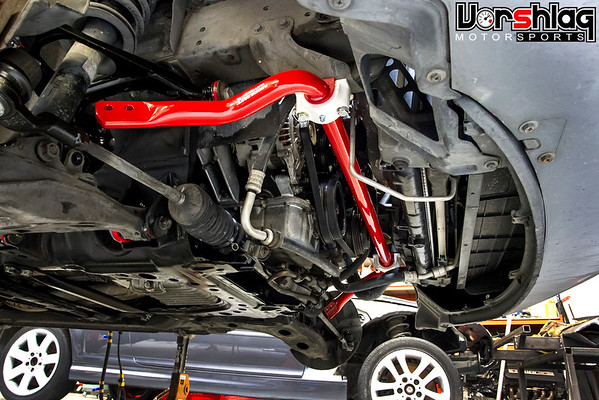

Like the car above - you don't need to think about Watts Links or control arms, you need REAL SPRING RATE increases (and thus real dampers) before you do anything else to the suspension.

After you get quality coilovers on your S197 with proper spring rates (

AT LEAST 4 TIMEs the OEM front rates) then you can experiment with swaybars effectively. Most times we see aftermarket front swaybars that are BOUND UP in the mounts. Out of the box virtually every aftermarket swaybar doesn't fit the chassis mount bushings, and it adds hundreds of pounds of roll resistance.

This is easy to check, and its happened to all of us. Disconnect both end links on a given swaybar and see if it rotates in the bushings with "pinkie finger effort". Most times I've seen an aftermarket bar it's so bound up that we can do pull ups on the swaybar... as in it takes 100-200 pounds of force to even move it. They NEVER fit well out of the box and the bushings and mounts usually need tweaks to get that "pinkie finger" low effort mounting. Not loose in the mounts, but FITTED PROPERLY in the mounts. It takes shimming the brackets, reaming the bushings to fit, or both.

Our first V8 BMW E36 above was a classic case of this. With an H&R front swaybar added, at the next autocross test event (shown above) the car pushed like mad (massive understeer) because it had too much front roll stiffness. It was getting up onto 2 wheels in transitions - too stiff! We took it back to the shop, put it on the lift, unhooked the endlinks, and I could hang my 200 pound body from the end of the swaybar. Wouldn't budge. We spaced the bracket down, ground the bushing a bit, got the bar to pivot freely, and then took it to another event... night and day difference. It was now neutral and the DEATH PUSH went away. No parts changed, not even swaybar settings, just fixed the swaybar pre-load in the mounts.

So look at your swaybars for this "bound up" condition, because it is ALL TOO COMMON. I've probably seen this 50 times in our shop with customer cars. That's something to worry about with swaybars, not their total deletion, good grief. And yes, some of the internet folks that swear their "no swaybar" setups are faster were likely victims of a "stuck" swaybar. Don't let that data confuse you....

/rant