Project Introduction - March 9th, 2020: Since our black 2015 Mustang GT (the #LS550 swap we call #Trigger) road race build is going so far beyond what we did on our red 2018 Mustang GT, or any other S550 we have worked on in the past 6 years, we figured it was time to move this car to its own build thread.

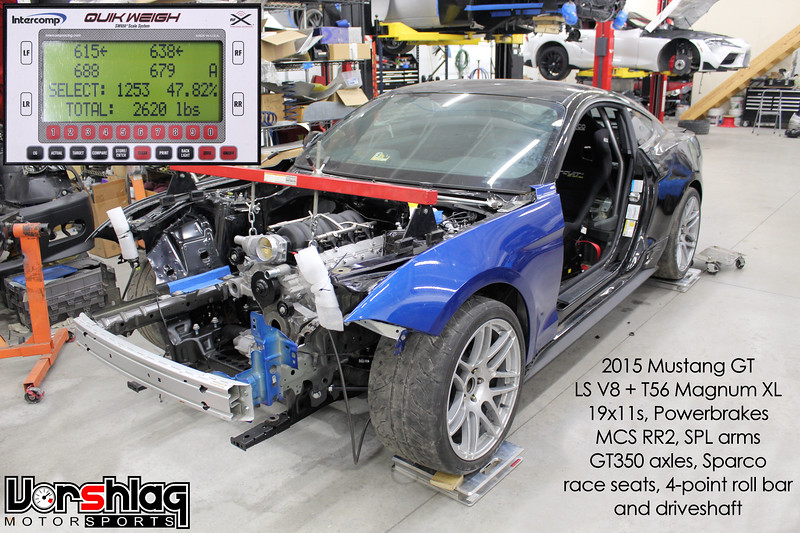

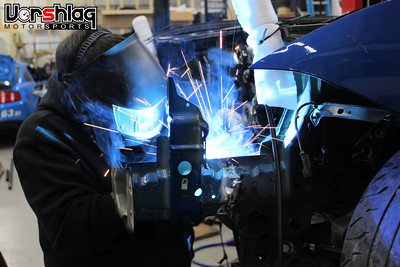

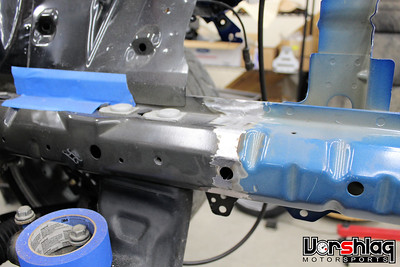

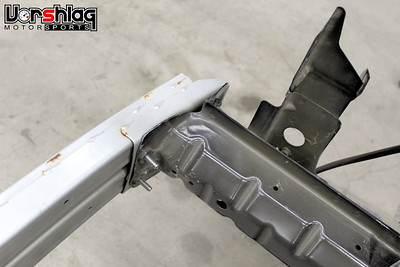

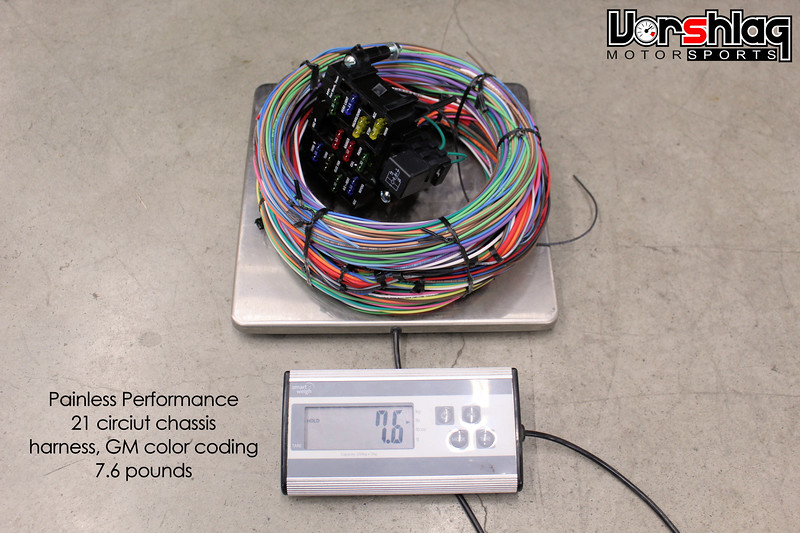

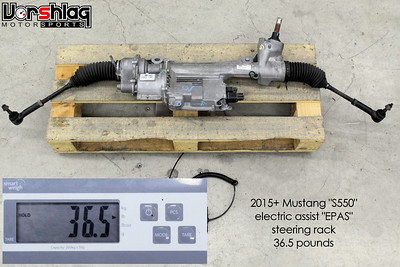

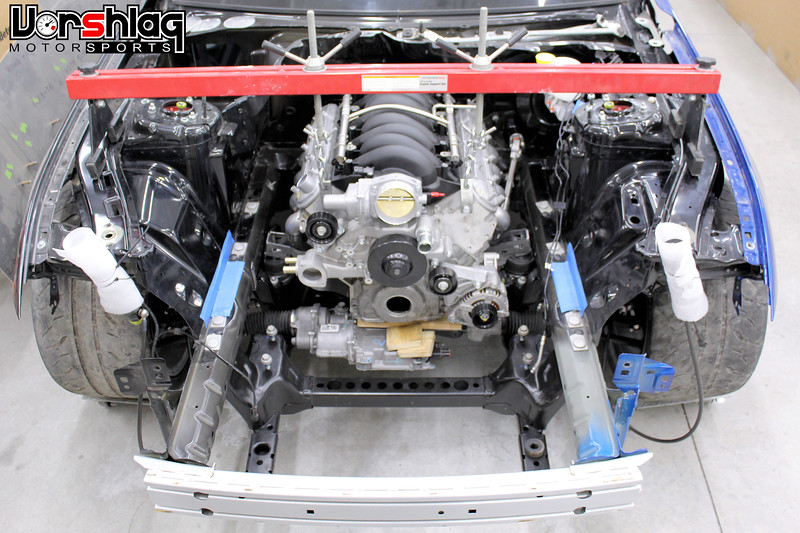

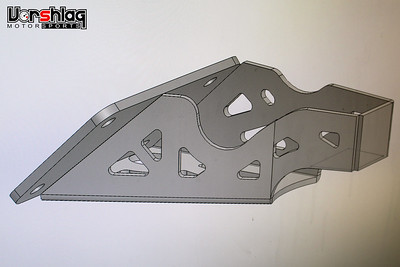

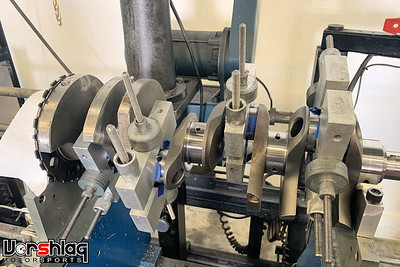

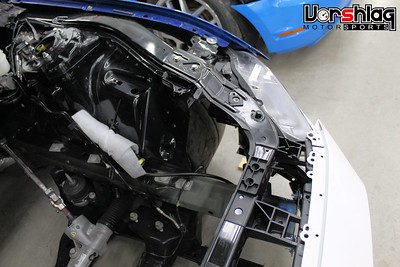

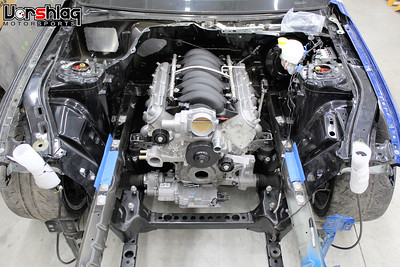

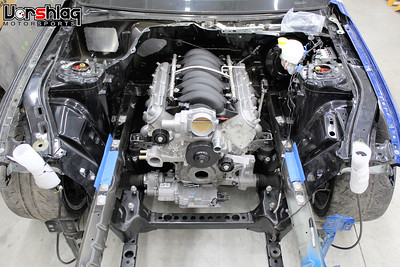

This build started as a salvage titled chassis purchased in August 2019 that was hit in the front and stripped of the drivetrain, wiring, brakes and pretty much anything of value. We bought it cheap and have been working to turn this into a race car to use to test parts and theories. We have already used this car to create our LS V8 swap using a T56 Magnum XL trans, repaired the bent frame rail and replaced the other bent bits, swapped in suspension/brake/wheel/tire/seats, and more. Since we have been working on this car more lately, we wanted to go back and summarize what we started with, show how we got to this point, and then continue the build updates for this car in this thread.

WHY A NEW THREAD + INITIAL S550 DEVELOPMENT

We have had an S550 Development Thread going since October of 2014, and we will keep the generic S550 work, all S550 parts development, and business related content posted there - even these LS550 specific tasks done to this 2015 GT will be cross-posted there. In that thread we have shown our initial S550 development work using tester's 2015 Mustang GT PP1 (camber plates, MCS coilovers, wheels, etc), then work on our red 2018 GT (below) starting in Feb 2018, some customer S550 cars, etc. Anything having to do with our 2015 #LS550 build will go in this new build thread, to keep it more focused.

Our red 2018 GT (above) went through a number of phases, and there was already some confusion between that car and our black 2015 build, as well as some S550 customer work shown in the main "development" thread. This new thread it would keep us from "crossing the streams". Also, in the Mustang specific forums where we are sponsors, we felt that moving the #LS550 thread out of our "vendor specific" sub-forums would make more sense. You don't tend to go diving into Vendor forums unless you are looking for something, and we would rather keep this build in the road racing / corner carver specific sections of those places.

The work we did in 2014-15 with Aaron's 2015 GT (above) and then later on our red 2018 GT would be considered our initial phase of our S550 development. In that time period we tackled a lot of basic issues, came up with a lot of fixes, and tested a lot of vendor's parts. We had 5 different damper sets on our 2018 GT alone, have made two S550 camber plate versions, fitted 18x11 and 19x11 wheels from Forgestar and MOMO. We have tested on track with 200TW and Hoosier tires up to 315mm, power mods that took the Gen III Coyote to 485 whp, base brakes / PP1 brakes/ Powerstop brakes, and brake cooling that ranged from 4" ducted backing plates to our more effective brake cooling deflector designs.

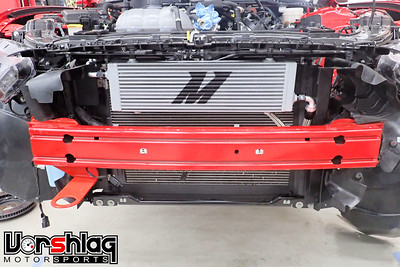

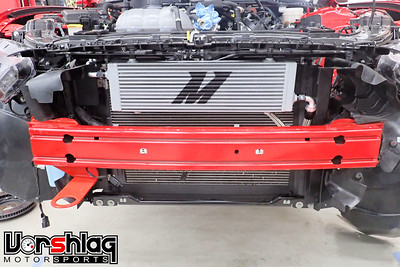

Safety gear upgrades we have developed included 4-point roll bar that we built, our new style of seat mounting brackets, and various racing seats and 6-point harnesses. We have always had a heavy S550 that ranged from 3550-3650 pounds. The high weight complicated the already high differential and engine fluid temps, so we worked with Mishimoto to develop an oil cooler for the 2018+ GT, installed their radiator, a vented carbon hood from Anderson, then started development on our own diff cooler. We also made tow hooks for the 2018+ GTs which proved to be popular.

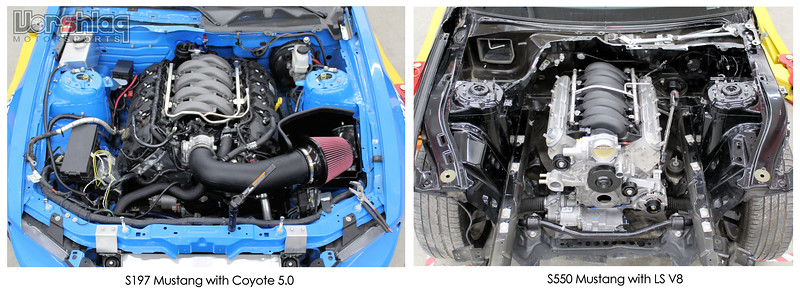

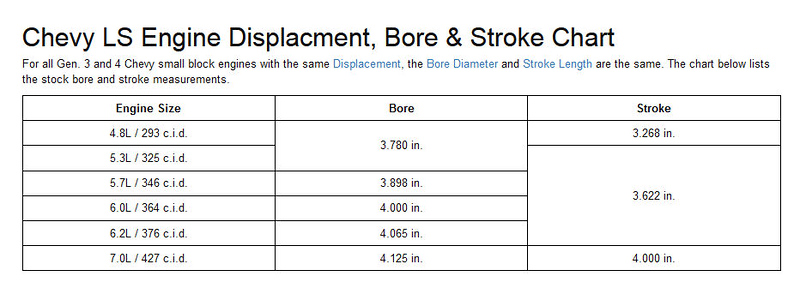

One thing always held us back - the restriction of not cutting the car. Why? To keep resale value at it's highest. This limited our 2018 GT to "little" 305 and 315mm tires and a relatively high total mass. The Coyote V8 is a great engine, but it has pretty hard upper limits for Naturally Aspirated horsepower. 500 whp is pretty much the bleeding edge limit, and resorting to higher revs or boost only leads to rapid engine destruction. That's not opinion - that's physics.

HOW TO GO FASTER IN AN S550?

With this #LS550 project we WILL BE cutting on the car. That allows some "Next Level" of development to happen. The most basic set of solutions to "going faster" in a road course setting with the S550 (or anything, really) includes: more tire, more power, more aero, less weight. It all really boils down to MORE.

To get to that Next Level would have required sacrificing the resale value we had in our low mileage 2018 GT, which we pulled from road course duties at less than 2500 total miles on the odometer. We cut up our "purchased new" 2011 GT (upper left) to add flares, wing, splitter, and ducted hood - which did make it significantly faster, but also made much harder to sell as a "semi-race car". We eventually found the right buyer, and the car brought good money, but it took nearly 18 months to sell that 2011 GT. We sold the 2018 GT for asking price in only 2 months of trying - since it wasn't "cut up" or radically modified.

The "financial lesson" about cutting on a relatively new car, which we learned with the 2011 GT above (and many other street cars we have modded), was what kept us from cutting on our 2018 GT. And also that led us to buy the cheap salvage 2015 Mustang rolling chassis....

FINDING A "CHEAP" S550 MUSTANG "RACE CAR" CHASSIS

After I got tired of making excuses about driving a 3800 pound street car (2018 GT) against "real race cars" in NASA TT and Optima series events, it was time to do something about it. We had considerable "internal debate" here at the shop about our "next big shop build". After looking at global sales numbers for the S550 Mustang relative to a number of other potential chassis. it was decided that a lightweight, caged, aero equipped, flared and ridiculous S550 build made the most sense. I put a call out online for a 2015-up S550 Mustang rolling chassis, but after looking locally and trolling salvage auctions for months it was a bust.

Then Steve Poe of Poe Motorsports put me in touch with The Parts Farm in Lyons, Georgia. This salvage yard buys wrecked V8 pony cars at salvage auctions to then strip and resell the drive trains, body parts, and other valuable bits. It took a bit of leg work, but once we found them, they put together a rolling chassis 2015 GT for us. Then it was just a matter of driving 1000 miles round trip to go get the car. We paid $2500 for this cream puff, which was thousands less than the much more wrecked cars we found on Copart auctions in Texas.

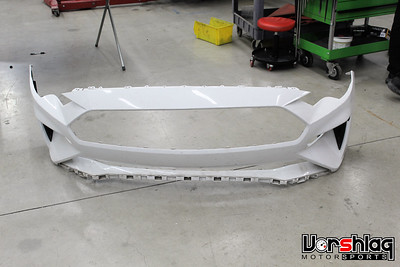

After I told them what I needed, they sent me a dozens of pics of the 2015 Mustang GT above, which they had already stripped of the 5.0L engine/trans/wiring and a number of other parts. This car was otherwise very rebuildable for a race car. The $2500 price was the best deal I had seen in months of looking at even less suitable candidates (some people wanted $10-15K for wrecked V6 Mustangs)

A long time friend of mine, Paul M, volunteered to co-drive with me for the 2000 mile round trip from Dallas to east Georgia and back. We left in the F350 and enclosed trailer at 5:30 am one Friday morning, drove all night and arrived at the farm-turned-salvage yard at 9:45 am Saturday morning. The folks there were helpful and already had the car ready to load. We pushed it near the trailer ramp, winched it inside, paid for the car, and we were back on the road 45 minutes later for the 1000 mile trip back to Dallas. It was a grueling 34 hour round trip, but we got back early enough to have the full day Sunday to catch up before going in to work on Monday.

Starting with this very low cost chassis allows us to cut anything we want - to fit wider tires, lower weight, add radical aero, and swap in a different engine - without ruining the value of a $35-40K+ new vehicle. Yes, this was a "wrecked car," but after selling off some bits we don't need, it's now a $1400 complete chassis that is 100% paid for. The main portions of the chassis, frame rails, and upper horns were straight, the doors close perfectly, and it has zero rust or other issues. We started with an initial weight at 2349 pounds (no engine, trans, or front brakes) and then began removing parts.

We took the weight of our 2018 GT (above left) in its final NASA TT2 trim at 3626 pounds with half a tank of fuel, which was as low of a fuel level we could run on track with the stock saddle tank. Then we got into the 2015 chassis. Removing the OEM front and rear seats, busted hood and bent bumper beam, and a few other items got it down to 2089 lbs. Even at that weight there was still carpet, a full dash, center console and both 84.2 pound doors in place. We speculated at the time that a sub 3000 pound fully caged S550 race car was possible.

At this point it was August 2019 and we had seen some weight drop and made a lot of plans. In September we pulled our 2018 GT from our event schedule and started removing many of the suspension, brakes, wheels, seats, safety gear, and hood from it. Much of this was to be moved over to this #LS550 chassis.

continued below

This build started as a salvage titled chassis purchased in August 2019 that was hit in the front and stripped of the drivetrain, wiring, brakes and pretty much anything of value. We bought it cheap and have been working to turn this into a race car to use to test parts and theories. We have already used this car to create our LS V8 swap using a T56 Magnum XL trans, repaired the bent frame rail and replaced the other bent bits, swapped in suspension/brake/wheel/tire/seats, and more. Since we have been working on this car more lately, we wanted to go back and summarize what we started with, show how we got to this point, and then continue the build updates for this car in this thread.

WHY A NEW THREAD + INITIAL S550 DEVELOPMENT

We have had an S550 Development Thread going since October of 2014, and we will keep the generic S550 work, all S550 parts development, and business related content posted there - even these LS550 specific tasks done to this 2015 GT will be cross-posted there. In that thread we have shown our initial S550 development work using tester's 2015 Mustang GT PP1 (camber plates, MCS coilovers, wheels, etc), then work on our red 2018 GT (below) starting in Feb 2018, some customer S550 cars, etc. Anything having to do with our 2015 #LS550 build will go in this new build thread, to keep it more focused.

Our red 2018 GT (above) went through a number of phases, and there was already some confusion between that car and our black 2015 build, as well as some S550 customer work shown in the main "development" thread. This new thread it would keep us from "crossing the streams". Also, in the Mustang specific forums where we are sponsors, we felt that moving the #LS550 thread out of our "vendor specific" sub-forums would make more sense. You don't tend to go diving into Vendor forums unless you are looking for something, and we would rather keep this build in the road racing / corner carver specific sections of those places.

The work we did in 2014-15 with Aaron's 2015 GT (above) and then later on our red 2018 GT would be considered our initial phase of our S550 development. In that time period we tackled a lot of basic issues, came up with a lot of fixes, and tested a lot of vendor's parts. We had 5 different damper sets on our 2018 GT alone, have made two S550 camber plate versions, fitted 18x11 and 19x11 wheels from Forgestar and MOMO. We have tested on track with 200TW and Hoosier tires up to 315mm, power mods that took the Gen III Coyote to 485 whp, base brakes / PP1 brakes/ Powerstop brakes, and brake cooling that ranged from 4" ducted backing plates to our more effective brake cooling deflector designs.

Safety gear upgrades we have developed included 4-point roll bar that we built, our new style of seat mounting brackets, and various racing seats and 6-point harnesses. We have always had a heavy S550 that ranged from 3550-3650 pounds. The high weight complicated the already high differential and engine fluid temps, so we worked with Mishimoto to develop an oil cooler for the 2018+ GT, installed their radiator, a vented carbon hood from Anderson, then started development on our own diff cooler. We also made tow hooks for the 2018+ GTs which proved to be popular.

One thing always held us back - the restriction of not cutting the car. Why? To keep resale value at it's highest. This limited our 2018 GT to "little" 305 and 315mm tires and a relatively high total mass. The Coyote V8 is a great engine, but it has pretty hard upper limits for Naturally Aspirated horsepower. 500 whp is pretty much the bleeding edge limit, and resorting to higher revs or boost only leads to rapid engine destruction. That's not opinion - that's physics.

HOW TO GO FASTER IN AN S550?

With this #LS550 project we WILL BE cutting on the car. That allows some "Next Level" of development to happen. The most basic set of solutions to "going faster" in a road course setting with the S550 (or anything, really) includes: more tire, more power, more aero, less weight. It all really boils down to MORE.

To get to that Next Level would have required sacrificing the resale value we had in our low mileage 2018 GT, which we pulled from road course duties at less than 2500 total miles on the odometer. We cut up our "purchased new" 2011 GT (upper left) to add flares, wing, splitter, and ducted hood - which did make it significantly faster, but also made much harder to sell as a "semi-race car". We eventually found the right buyer, and the car brought good money, but it took nearly 18 months to sell that 2011 GT. We sold the 2018 GT for asking price in only 2 months of trying - since it wasn't "cut up" or radically modified.

The "financial lesson" about cutting on a relatively new car, which we learned with the 2011 GT above (and many other street cars we have modded), was what kept us from cutting on our 2018 GT. And also that led us to buy the cheap salvage 2015 Mustang rolling chassis....

FINDING A "CHEAP" S550 MUSTANG "RACE CAR" CHASSIS

After I got tired of making excuses about driving a 3800 pound street car (2018 GT) against "real race cars" in NASA TT and Optima series events, it was time to do something about it. We had considerable "internal debate" here at the shop about our "next big shop build". After looking at global sales numbers for the S550 Mustang relative to a number of other potential chassis. it was decided that a lightweight, caged, aero equipped, flared and ridiculous S550 build made the most sense. I put a call out online for a 2015-up S550 Mustang rolling chassis, but after looking locally and trolling salvage auctions for months it was a bust.

Then Steve Poe of Poe Motorsports put me in touch with The Parts Farm in Lyons, Georgia. This salvage yard buys wrecked V8 pony cars at salvage auctions to then strip and resell the drive trains, body parts, and other valuable bits. It took a bit of leg work, but once we found them, they put together a rolling chassis 2015 GT for us. Then it was just a matter of driving 1000 miles round trip to go get the car. We paid $2500 for this cream puff, which was thousands less than the much more wrecked cars we found on Copart auctions in Texas.

After I told them what I needed, they sent me a dozens of pics of the 2015 Mustang GT above, which they had already stripped of the 5.0L engine/trans/wiring and a number of other parts. This car was otherwise very rebuildable for a race car. The $2500 price was the best deal I had seen in months of looking at even less suitable candidates (some people wanted $10-15K for wrecked V6 Mustangs)

A long time friend of mine, Paul M, volunteered to co-drive with me for the 2000 mile round trip from Dallas to east Georgia and back. We left in the F350 and enclosed trailer at 5:30 am one Friday morning, drove all night and arrived at the farm-turned-salvage yard at 9:45 am Saturday morning. The folks there were helpful and already had the car ready to load. We pushed it near the trailer ramp, winched it inside, paid for the car, and we were back on the road 45 minutes later for the 1000 mile trip back to Dallas. It was a grueling 34 hour round trip, but we got back early enough to have the full day Sunday to catch up before going in to work on Monday.

Starting with this very low cost chassis allows us to cut anything we want - to fit wider tires, lower weight, add radical aero, and swap in a different engine - without ruining the value of a $35-40K+ new vehicle. Yes, this was a "wrecked car," but after selling off some bits we don't need, it's now a $1400 complete chassis that is 100% paid for. The main portions of the chassis, frame rails, and upper horns were straight, the doors close perfectly, and it has zero rust or other issues. We started with an initial weight at 2349 pounds (no engine, trans, or front brakes) and then began removing parts.

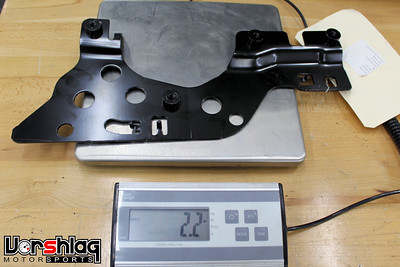

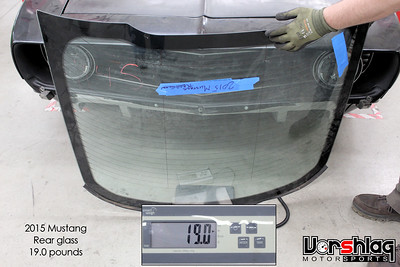

We took the weight of our 2018 GT (above left) in its final NASA TT2 trim at 3626 pounds with half a tank of fuel, which was as low of a fuel level we could run on track with the stock saddle tank. Then we got into the 2015 chassis. Removing the OEM front and rear seats, busted hood and bent bumper beam, and a few other items got it down to 2089 lbs. Even at that weight there was still carpet, a full dash, center console and both 84.2 pound doors in place. We speculated at the time that a sub 3000 pound fully caged S550 race car was possible.

At this point it was August 2019 and we had seen some weight drop and made a lot of plans. In September we pulled our 2018 GT from our event schedule and started removing many of the suspension, brakes, wheels, seats, safety gear, and hood from it. Much of this was to be moved over to this #LS550 chassis.

continued below