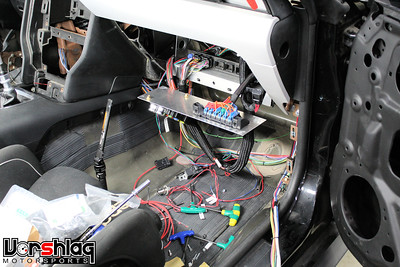

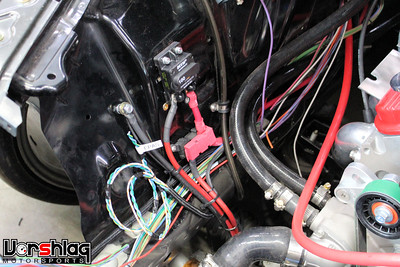

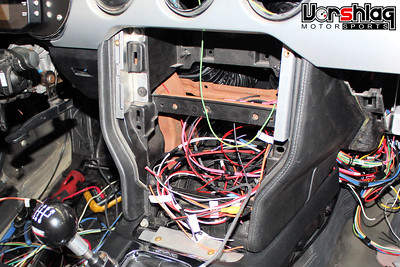

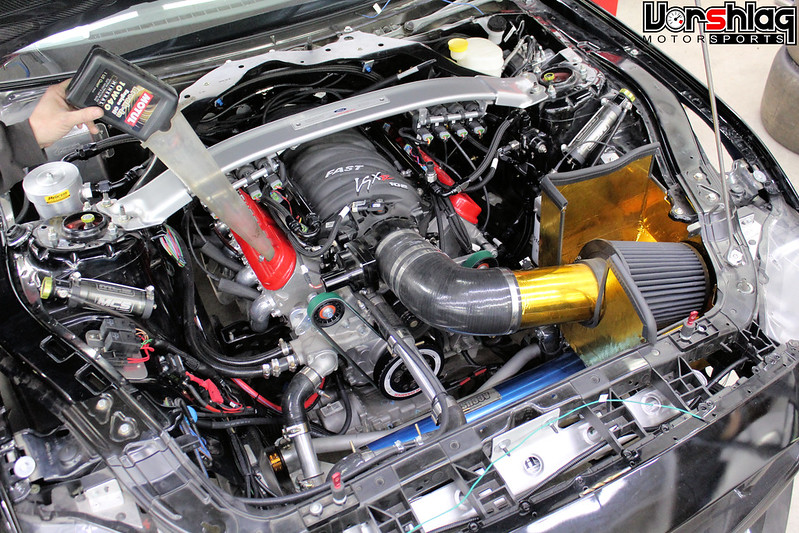

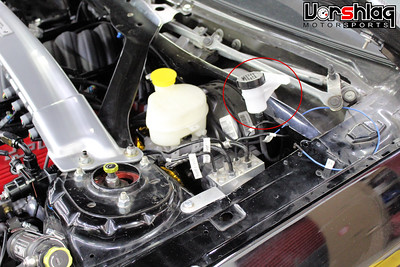

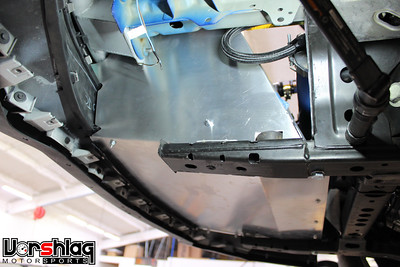

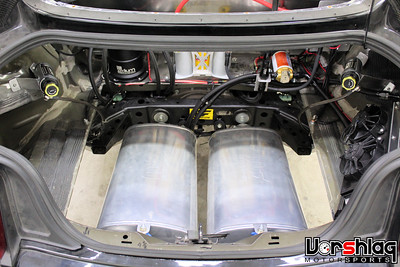

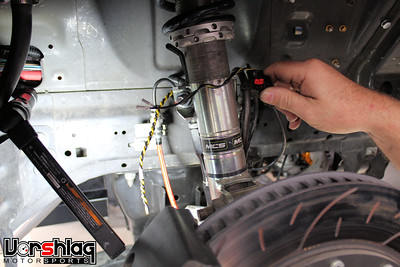

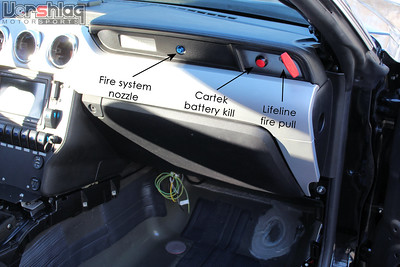

Adding this rear seat to trunk firewall was a good idea as we had the Radium surge tank with two fuel pumps, differential cooler pump and other flammable fluids and electrical bits going on back there. This is the trunk wiring almost finished, above. The negative cable goes from the Optima battery to the Cartek kill and then to a big lug on the chassis. If you trigger the Cartek it kills the ground to the battery and shuts down everything.

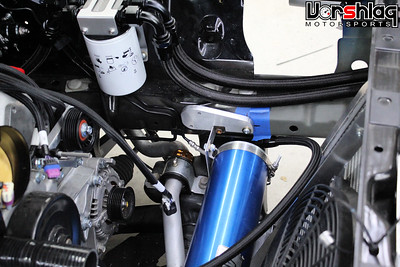

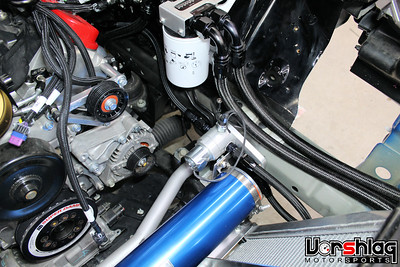

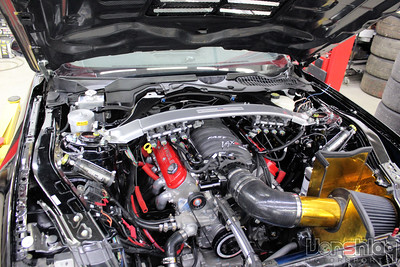

Once the battery / Cartek / 200 amp breaker were wired in, the main battery cable was run forward through the cabin to another bulkhead pass-thru at the engine bay firewall (can't find the pic), then routed down to the starter. The starter solenoid wires were run from the Painless Harness and to our push button starter.

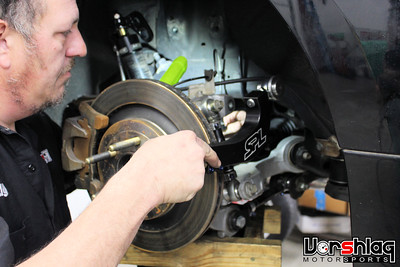

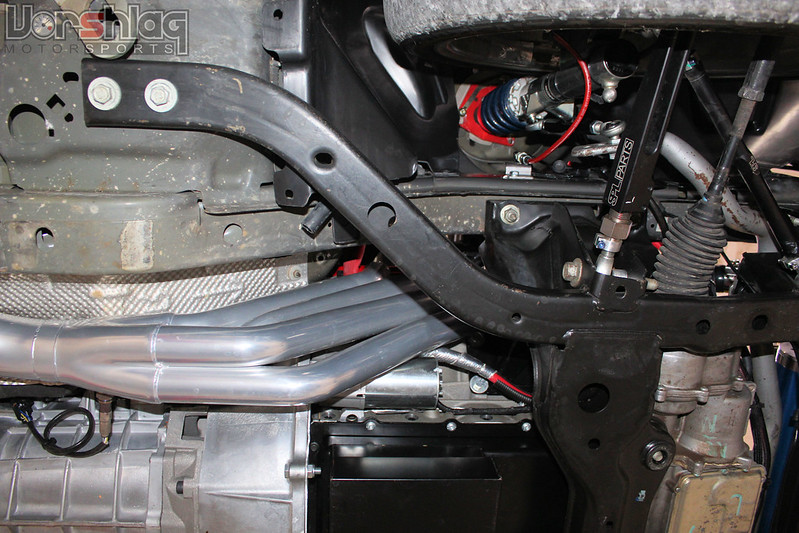

This is just the same LS1 starter we sell for all of our LS swaps, and it works great. Brad wrapped the areas of the cable and solenoid trigger with some heat wrap, as they are close to the header. If we notice it getting heat soaked by the proximity to the ceramic coated stainless header we will add a heat shield around the starter - but so far, so good.

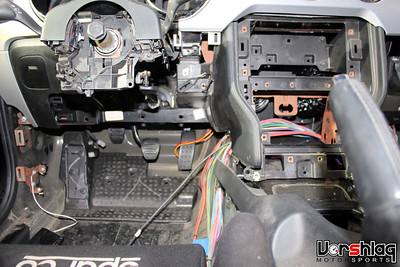

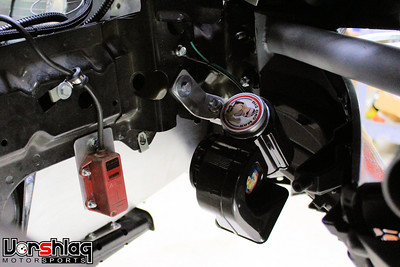

There are lots of little systems that we have wired in - the AMB transponder, a big loud horn, the brake pedal switch. I will cover the important systems in their own sections.

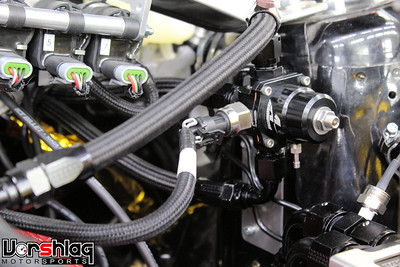

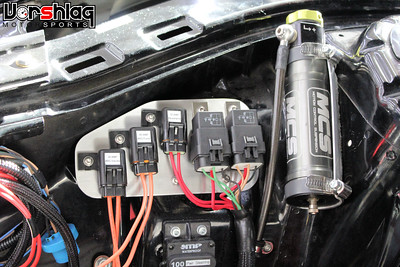

FUEL PUMP PDM CONTROLLER

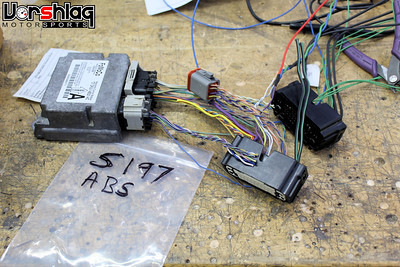

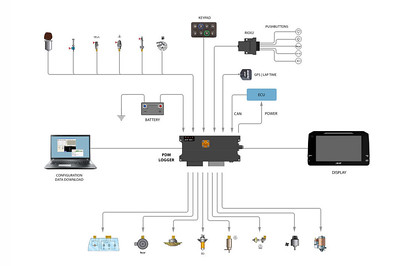

Programmable Power Distribution Management or "PDM" systems are all the rage the last 3-5 years in Motorsports. These are used widely in industry (my John Deere tractor has a PDM, and OEM car makers use them also) to minimize discrete wiring runs from every switch to each powered motor. This bundle of wires is replaced with a CAN network that sends commands to the devices, removing a lot of wiring and relays from a vehicle, and allowing some basic ladder logic to control multiple systems - based on alarm conditions or "if/then" logic.

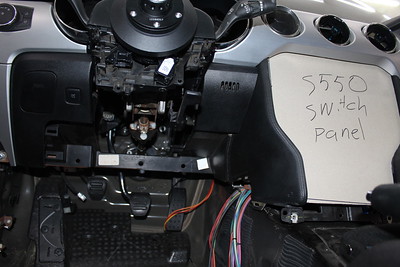

Sounds great, right? Well - it is! Right up until the point when your PDM takes a dump. I've heard from more than a few racers that they always keep a 100% backup PDM on hand for critical race weekends. Instead of a spare relay or switch, you need a spare PDM! Still, the desire to have this build on "the cutting edge" of PDM hotness inspired me to order the AiM PDM32 system. Twice.

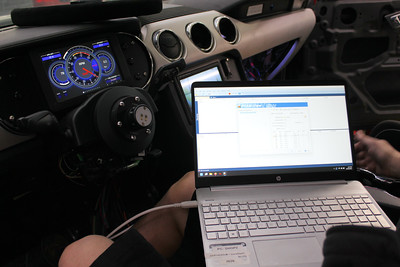

After TWO YEARS of waiting for two orders from AiM Sports for PDM systems, starting back in early 2020, we threw in the towel. Each order we sent them was ignored for 6+ months and every time we asked for an update it was "8-12 weeks" out. We cancelled both orders and went another route. AiM Sports, being based out of Italy, had MAJOR supply chain and remote employee work issues getting these new PDM systems launched during the Global Pandemic. Even now in 2023, fully THREE YEARS after this new system was announced and released, they still have very real problems. I do not recommend going this route, for now, until more racers / guinea pigs have helped AiM work out the bugs in their PDM. And with a Holley, well... none of the display would have worked anyway.

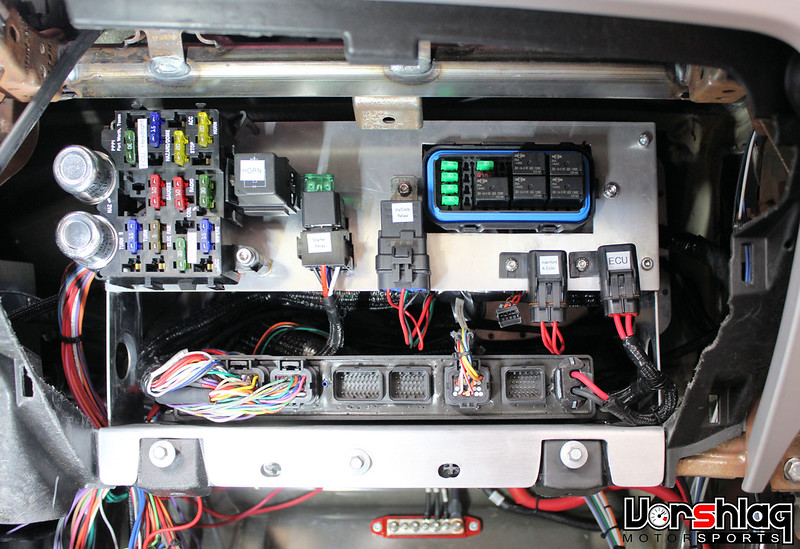

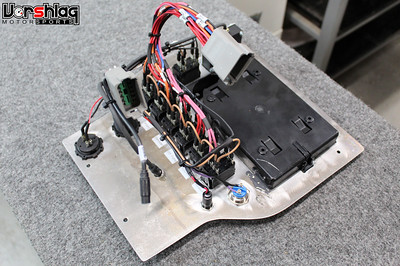

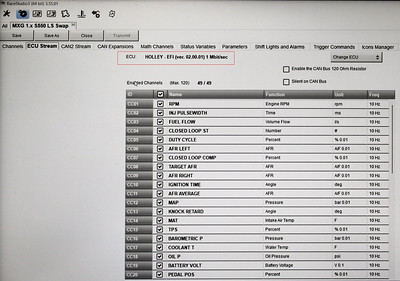

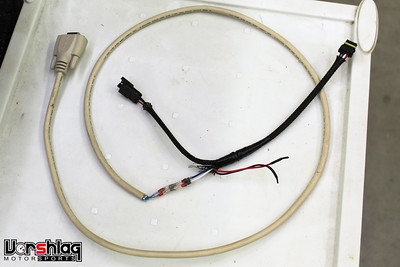

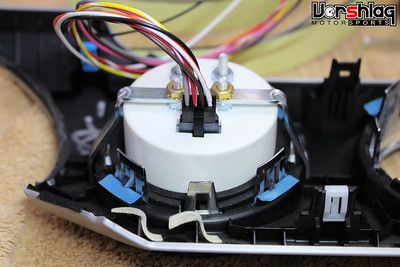

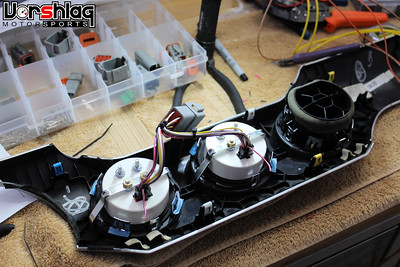

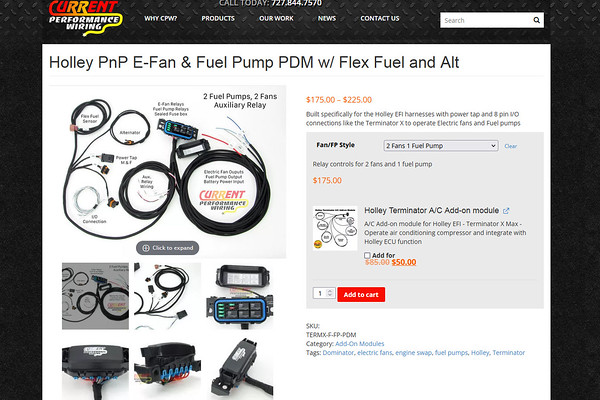

Instead of waiting years longer, we ordered this harness from Current Performance. This "mini PDM" was a $225 unit made specifically for the Holley EFI system we are using. This can control 2 Fans 2 Pumps plus an auxiliary system. Pretty basic but it is a programmable "PDM" in the strictest sense of the definition.