continued from above

Mounting it close to the windshield is tricky, but we built a special RAM mount on the FR-S where it can sit "right side up", above left. This is normally where we have Amy's cell phone holder, for street use in that car, and we swap in this vidcam for track events. We just added that type of mount to the Mustang and the video is complete garbage - too far from the glass? Don't know.

I will show some of this video from Optima @ NCM next time taken with this new "right-side up" dash mount, but it was not very good. When using this vidcam with a suction cup mount and running the camera "upside down" means I have to flip the video and re-render before I can bring it into Race Render, to merge it with data. Then it goes back for a 3rd round of edits and another render in my video editing software once the data is overlaid. Real time killer... I usually spend 90 minutes to make a 3-5 minute in-car video. It didn't help that I had a dead CPU fan for almost a year, which crippled rendering times (just fixed that - and my PC is 5x faster rendering)

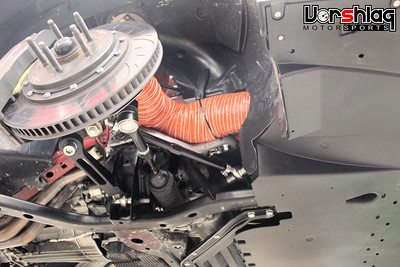

I've also wanted to get back to a "roll bar mount" camera location using a "narrow" Field of View lens. My previous Sony vidcam (2012-2016) worked pretty well, and even had a nice wired remote (with indicators for on/off, recording, etc), with a narrow FOV and a real adjustable lens. The quality from that 7+ year old 1080P vidcam started to look pretty dated, and the lack of a external mic was a real killer. Now that the 2018 Mustang has a roll bar (like we ran in our 2011 GT) it is time to install the I/O Port vidcam mount behind the driver, get a modern vidcam with a narrow FOV lens, and finally be able to see what the idiot driver is doing as well as a good view out the front.

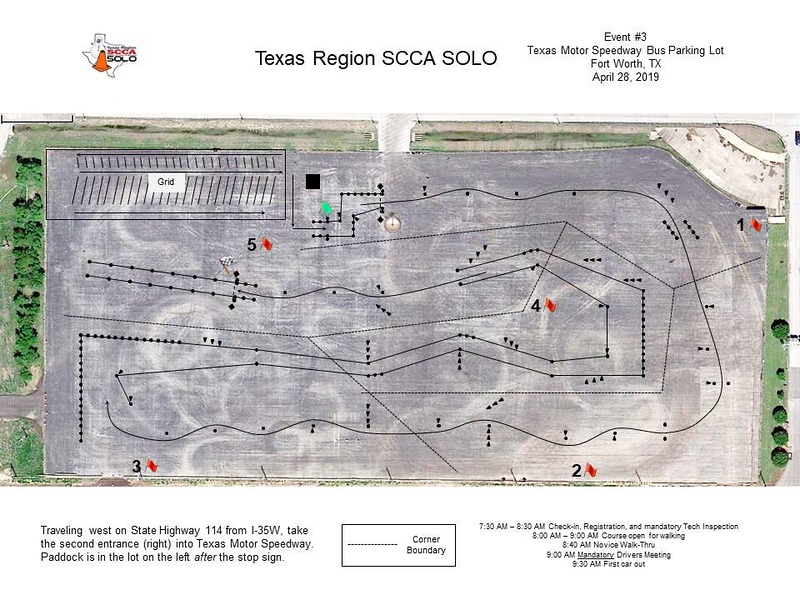

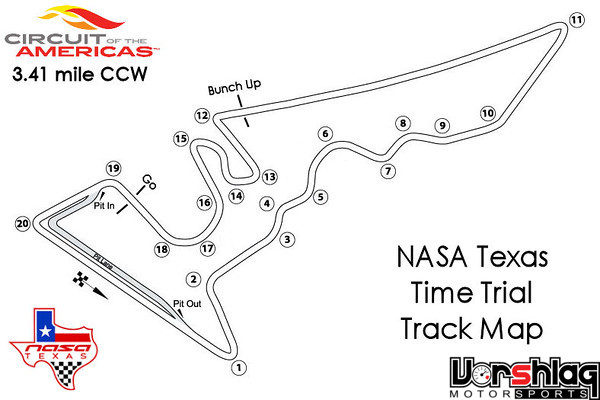

If you have been following my build threads for the past 8+ years you will have seen that I don't drive on track without my AiM Solo. I have two of these units, the $399 SOLO (my loaner/spare) and the $799 SOLO DL (which can read data via OBDII or CAN). There are newer units called the SOLO 2 & SOLO2 DL, but they don't have a lot of new features (and they shipped with a few bugs). Again, merging the captured data to the video is a bit of a pain in the ass, and its something that gobbles up time after every event. I've also never data logged any autocross runs (until recently), but I knew it was possible with the AiM SOLO and a custom course setup for the day (walking the course to "set" the GPS points for a separate start and finish).

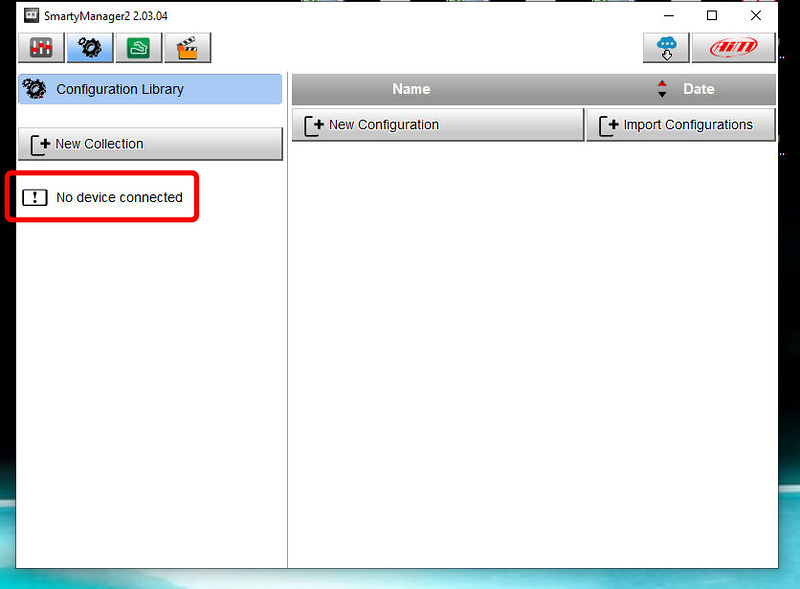

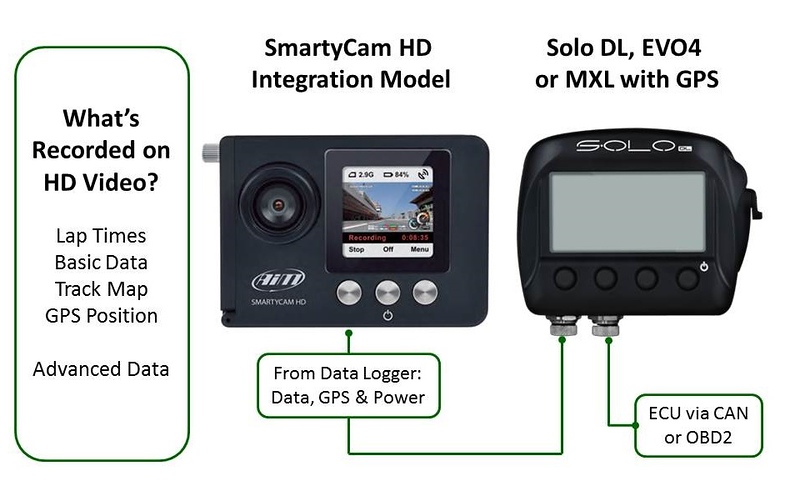

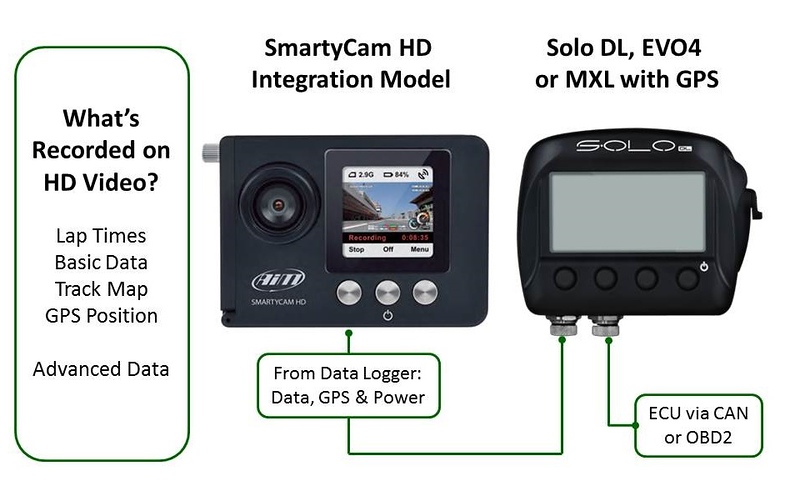

The obvious answer to all of these issues - if you ask anyone online - is the AiM SMartyCam HD. This $1000 camera can "talk" to the AiM SOLO (as well as AiM's other data logging digital dashes) and merges data and video real time. It also auto-starts and auto-stops, well according to the literature. We have sold and installed a number of these for customers, so I figured it was finally time to test this on the Mustang.

Crucially, I have never personally setup/used/tested one of these SmartyCams with an AiM or digital dash. This is how these two devices are supposed to be connected together and to the car. I have the OBDII/CAN wiring cable, and the SmartyCam came with the 5 pin to 7 pin AiM cable needed to connect to the SOLO DL. So now I need to learn to use these two devices for future videos - how hard can it be?

continued below

Mounting it close to the windshield is tricky, but we built a special RAM mount on the FR-S where it can sit "right side up", above left. This is normally where we have Amy's cell phone holder, for street use in that car, and we swap in this vidcam for track events. We just added that type of mount to the Mustang and the video is complete garbage - too far from the glass? Don't know.

I will show some of this video from Optima @ NCM next time taken with this new "right-side up" dash mount, but it was not very good. When using this vidcam with a suction cup mount and running the camera "upside down" means I have to flip the video and re-render before I can bring it into Race Render, to merge it with data. Then it goes back for a 3rd round of edits and another render in my video editing software once the data is overlaid. Real time killer... I usually spend 90 minutes to make a 3-5 minute in-car video. It didn't help that I had a dead CPU fan for almost a year, which crippled rendering times (just fixed that - and my PC is 5x faster rendering)

I've also wanted to get back to a "roll bar mount" camera location using a "narrow" Field of View lens. My previous Sony vidcam (2012-2016) worked pretty well, and even had a nice wired remote (with indicators for on/off, recording, etc), with a narrow FOV and a real adjustable lens. The quality from that 7+ year old 1080P vidcam started to look pretty dated, and the lack of a external mic was a real killer. Now that the 2018 Mustang has a roll bar (like we ran in our 2011 GT) it is time to install the I/O Port vidcam mount behind the driver, get a modern vidcam with a narrow FOV lens, and finally be able to see what the idiot driver is doing as well as a good view out the front.

If you have been following my build threads for the past 8+ years you will have seen that I don't drive on track without my AiM Solo. I have two of these units, the $399 SOLO (my loaner/spare) and the $799 SOLO DL (which can read data via OBDII or CAN). There are newer units called the SOLO 2 & SOLO2 DL, but they don't have a lot of new features (and they shipped with a few bugs). Again, merging the captured data to the video is a bit of a pain in the ass, and its something that gobbles up time after every event. I've also never data logged any autocross runs (until recently), but I knew it was possible with the AiM SOLO and a custom course setup for the day (walking the course to "set" the GPS points for a separate start and finish).

The obvious answer to all of these issues - if you ask anyone online - is the AiM SMartyCam HD. This $1000 camera can "talk" to the AiM SOLO (as well as AiM's other data logging digital dashes) and merges data and video real time. It also auto-starts and auto-stops, well according to the literature. We have sold and installed a number of these for customers, so I figured it was finally time to test this on the Mustang.

Crucially, I have never personally setup/used/tested one of these SmartyCams with an AiM or digital dash. This is how these two devices are supposed to be connected together and to the car. I have the OBDII/CAN wiring cable, and the SmartyCam came with the 5 pin to 7 pin AiM cable needed to connect to the SOLO DL. So now I need to learn to use these two devices for future videos - how hard can it be?

continued below