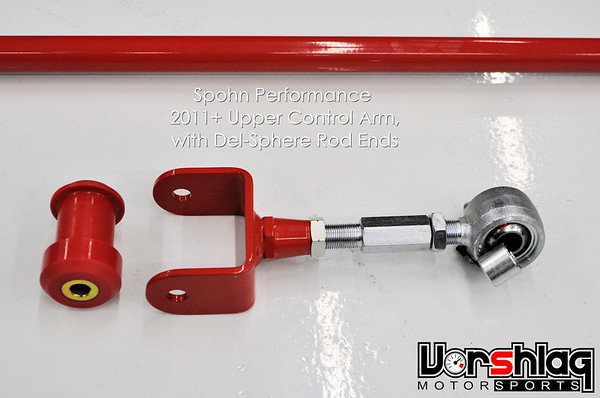

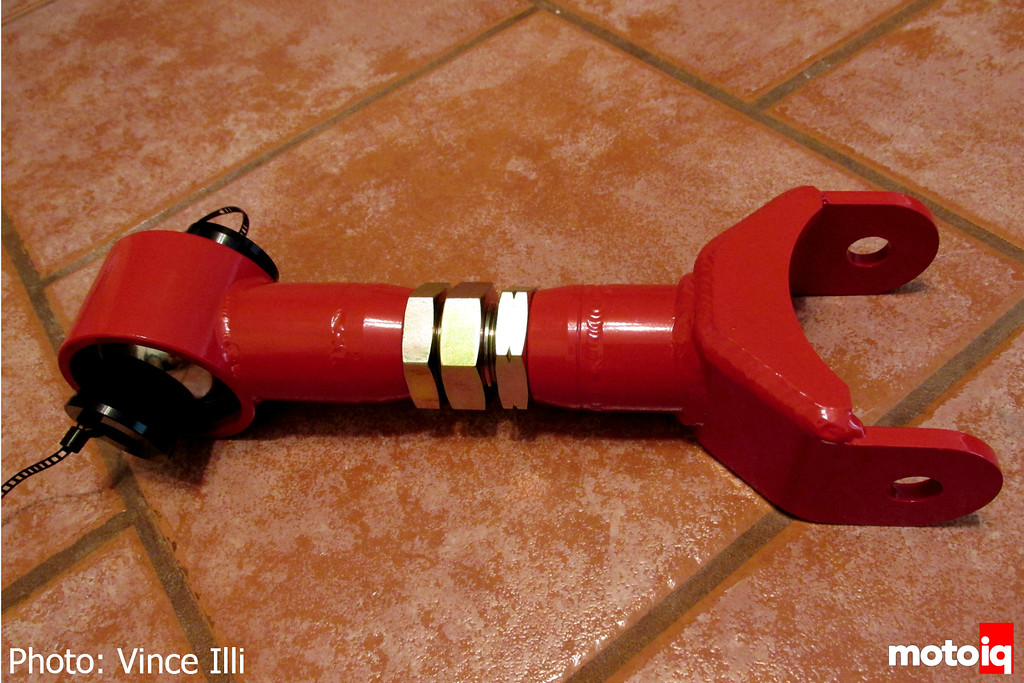

On paper these Delp-Sphere bearings are the ultimate in streetable performance for a multi-axis of rotation bushing. It has the firmness or Delrin, the ease of rotation of a spherical, and the Delrin bushing material is just enough of an NVH soak-up to allow for streetability. They are also adjustable, rebuildable, and greaseable via the included grease zerk - and streetable. Sign me up,

right?

Well... not so much, in practice. We used these Del-Sphere bushing ends in a Spohn Panhard bar and a UCA (also from Sphon) on our S197 and they were all a noisy, clunking mess. We re-adjusted the Del-Sphere ends a few times, greased them, called Spohn for help, tried just the Panhard bar by itself, but the noises never went away. And we're a suspension shop, so its not like we were clueless here. I couldn't wait to get these parts off the Mustang - all of this is still sitting in my shop, nearly new, and for sale on our

Clearance Page at a steep discount. I really

really wanted these bushings to work, and was envisioning all sorts of things we could do with these Del-Sphere joints. So disappointing!

I won't even get into how poorly the UCA bushing fit the upper mount, but long story short - it wasn't even close. We machined our own bushing inserts and it helped a little, but the noises never went away.

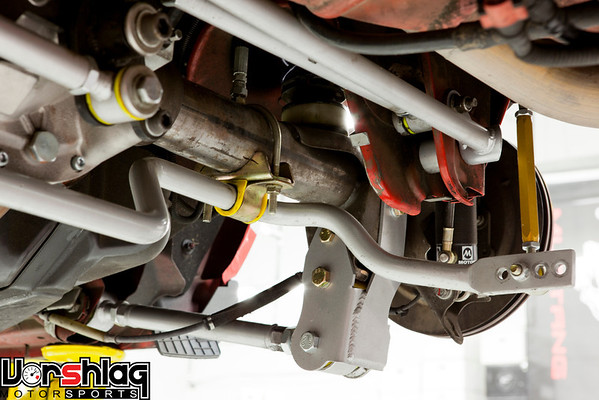

Replacing the Spohn UCA with the Multimatic $700 Boss 302-S/R UCA with a spherical bushing cured all of the noises and removed the slop. An expensive arm, to be sure, but the only one we tried that actually fit the mount properly.

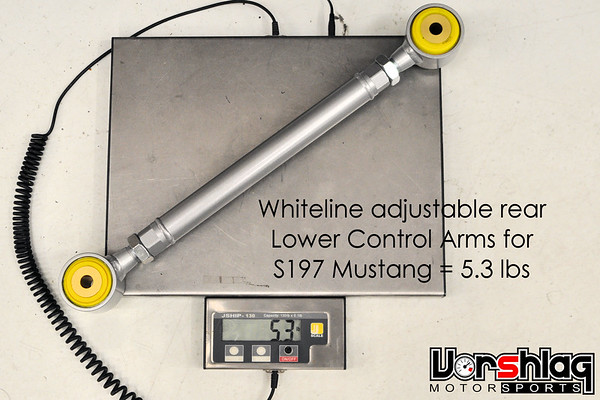

So if you take anything from this it is: avoid the Del-Sphere bushings until they have them sorted out a little better. We had nothing but bad luck with those. The Whiteline LCAs and Panhard, on the other hand, work perfectly. Their "polymer" bushings allow enough rotating but don't have the slop or compliance of the OEM rubber ends to allow a lot of movement. All of these Mustang-specific items are fabricated in Southern California, too.

Even if you don't

buy them from Vorshlag, trust me - these WL LCAs and Panhard bars are legit, and they both work for racing and street use alike (I'm still not a fan of the wL UCA, however - and I might get some grief from this for saying that). We've sold hundreds of these WL LCA and Panhard set-ups and there's not one customer yet that has come back and said "These make noise". Not one. I can't say that about many things, honestly...

Cheers,

It's a corner carver.

It's a corner carver.