Good question by the OP. The best way to see what the "right" settings are for the two adjustable swaybars is to do an autocross or track test. I assume you are using an S197, as you mention GT500 brakes. Here is how we did autocross testing on our S197 Mustang after adding the adjustable Whiteline swaybars. This is copied from my

August 31, 2012 post in our S197 project build thread.

========

August 30, 2012 - Private Autocross Testing

We had not autocrossed the Mustang since the late May "Spring Nationals" at Lincoln, so yesterday we did twelve autocrosses worth of runs at a private test event. With the 315/35/18 Kumho V710s still mounted on the Forgestar 18x11/12 wheels from the late June track day event, and located farther inboard by 1/2" from before, we loaded the Mustang onto the trailer and crammed in all of our gear. We brought more tools and equipment than we ever have, with a generator and air compressor, air tools, multiple floor jacks, extra springs, and all of our normal gear + our Farmtech timing system. We were loaded for war!

Like on our

August 2nd Test in Brianne's Pikes Peak Subaru where I got to drive that beast around an improvised road course at 130+ mph, we rented the "Mineral Ring" once again. Getting this 62 acre paved site on a week day is a breeze if you know the right person to call, so we headed out yesterday with the Mustang and our gear. Its 2+ hours each way from our shop to this facility in Mineral Wells, TX, and it always ends up being a battle to miss traffic across Dallas and Ft. Worth along the route. We hit 8 am traffic leaving and 5 pm traffic coming back, but we got a lot accomplished in about 10 hours.

Once we arrived we set up the old "Hollis Test Course" that was painted on the site for the past 6 years or so. Laid out about 50 cones, set-up the timers, and unloaded the Mustang. Conditions for August in Texas were as perfect as they get: sunny and clear with 88°F tempts and a nice 10-15 mph breeze all day. It crept up to 98°F by 2 pm but it was still pretty comfortable, considering it wasn't 110°F with a dead calm.

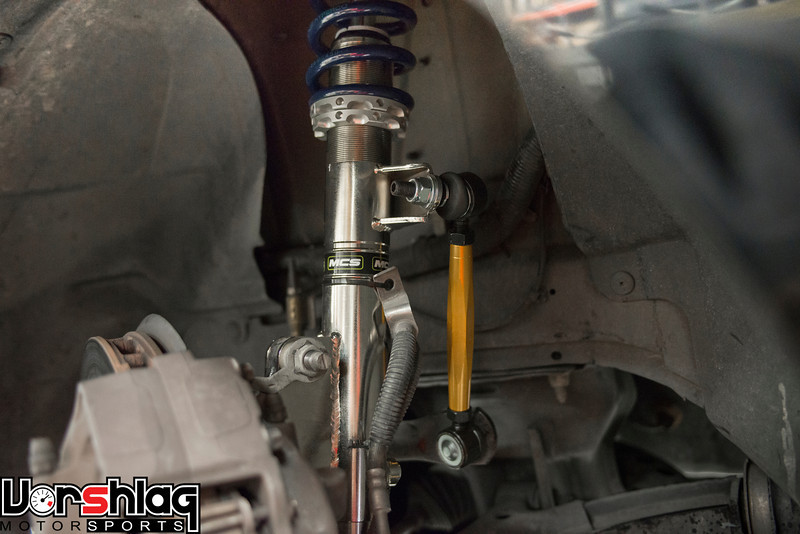

We started with a quick alignment check, setting front camber to -3.6° and toe to +1/8" out. Ride heights were already set fairly high, as we cannot lower the car as much as we like without knocking the rear geometry all to crap (those $100 relocation brackets work wonders, if only Street Prepared would allow them). Tire pressures were set at 35 psi front, 32 psi rear and the Moton ClubSport 2-way shocks were set at the middle rebound and compression settings front and rear. The Whiteline swaybars were set in their middle settings front and rear as well. Blue tape was placed on sections where we thought the tires could rub, the video camera was installed, and the new AIM Solo timing display was set-up for this course. Then I started taking laps....

Some early and some late test laps in the Mustang - click for video

This is a course I have driven hundreds of times so it usually doesn't take long before I am familiar with the course layout and my times stabilize within a tenth. Then we can make adjustments and check times - I let the clocks by the guide and not my "impressions". The AIM Solo was within hundredths of the Farmtek timers so I could see my laps real time. I took 2 hot laps at a time going clockwise on a course with a single start-stop line. In the video above you can hear me keeping notes, but Jason kept a full log of adjustments and lap times throughout the 3 hours of test driving I did. Ryan was busy all day making set-up changes to the bars, shocks, alignment and tire pressures. Plus we had one unexpected delay - a flat tire.

A flat out at the Mineral Ring it shouldn't be much of a surprise, as we got a flat in Brianne's Subaru at the same site a month ago (which shut down our testing early that day), but this time

we were prepared. Theoretically we are always learning from our past mistakes, right? So I had just gone out for a two lap blast but after the 2nd slalom cone I new something was "off". The car wouldn't turn right the the left front tire was howling under load - I waived off the lap quickly and got back to the trailer for a look. Yep, there was a pin hole in the left front and it was deflating fast. With a plug in the tire, the generator fired up and the compressor buzzing along, the tire was fixed, aired up, and I was back on course in about 3 minutes.

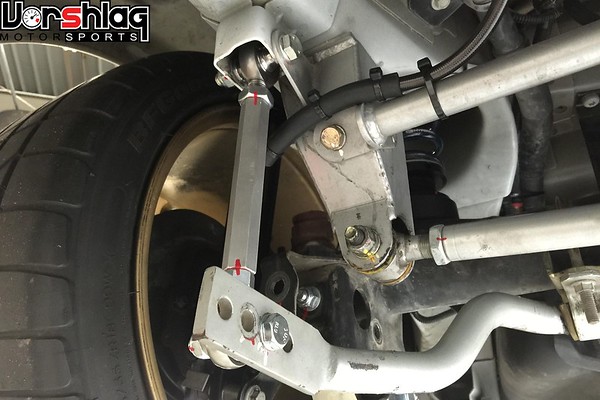

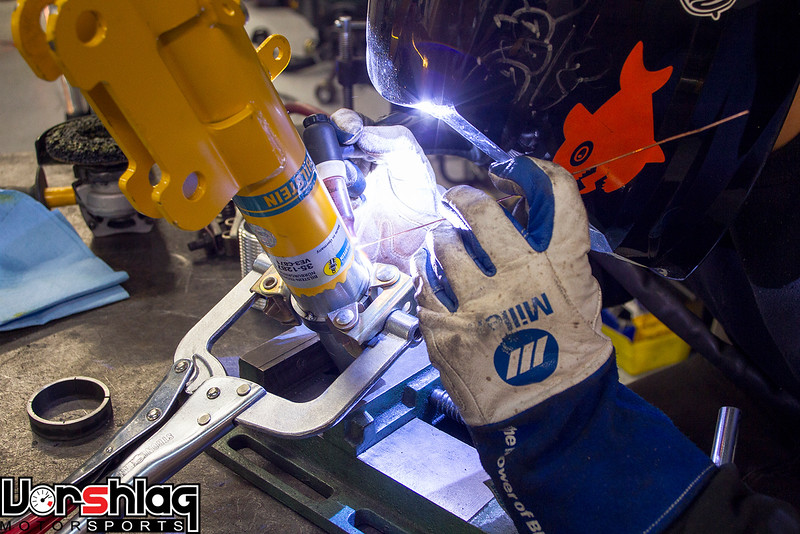

Over 3 hours of testing I made a total of 38 laps, and finished with blisters on my hands and a shoulder injury that was howling from some violent corrections I had to make using some of the wackier settings we tried, but we made it through the full sweep of component adjustments we wanted to attack. The new bars worked great and had more adjustments than many others out there with 4 holes per side. The rear tires were no longer rubbing and tucked inboard for a 1" narrower track than before. The Mustang was handling better than ever, especially in slaloms, where I could violently throw it back and forth. The pictures show that the lateral axle movement is much reduced from before (when we had a Panhard rod), and it was easier to drive. We had fixed some other long standing issue, too, but I forget what that was at the moment? It will come back to me.

After 3 hours in the car I was pretty hot, sweaty, sore and tired; so were Jason and Ryan, who did most of the heavy lifting with the test adjustments. My driving was starting to get sloppy by about lap 30, where I could only do 1 clean lap out of 2. The temps were climbing towards 100°F so we called it a day. After we loaded back up, grabbed a late lunch, we headed back to the shop in Plano and made it back by 5:45 pm. We have a lot of new cut vinyl graphics and decals to install today that Jason has been working on for the past few days. The graphic design is all Amy's doing, and not at all my thing. If you see the car and have any comments, direct them to her!

We are mounting up a sticker set of 315/30/18 Hoosier A6 tires, and I hope this is the right tire choice. I know that 335's would rub the fenders almost as badly as the 345s did, so I am staying safe with the 315s all around. It will likely always push (understeer) with such a non-square set-up anyway (like it did with the 315/345s we ran before).

======

What we found in this test, starting at full soft on each bar and doing laps at every setting... is that with these 315mm R compound tires and even 450F/175R coilover spring rates, the

car was faster with the front and rear bar set to full stuff. We tested one end first, then the other, and the timers proved this to us.

After the next event we did in the car with this setup (2012 Solo Nationals) we upped the spring rates from 450F/175R to 550F/250R, and the lean went down and the car got faster. Later we went to 800F/350R, and it was faster still. By 2013 we were almost exclusively doing NASA Time Trial events, and even on a road course the same basic setup still worked better with the bars at full stiff. These

heavy pony cars need ALL the swaybar and a LOT of spring rate to control their movements.

With the soft lowering springs the OP has (all lowering springs are super soft - no matter what "Rating" they tout; its fake numbers) I suspect the ideal setup to keep the tires from rolling over will still be to set the bars at full stiff. Just my $.02.

Cheers,