raredesign

forum member

I did not keep up with posts here while finishing the build, so I thought I would try to summarize and catch up.

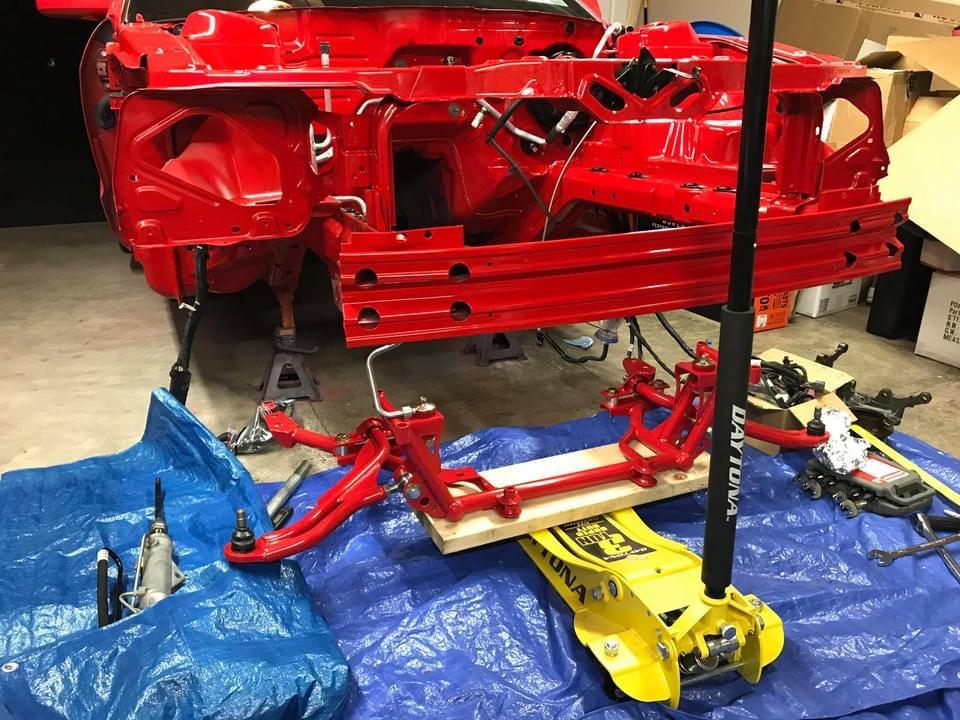

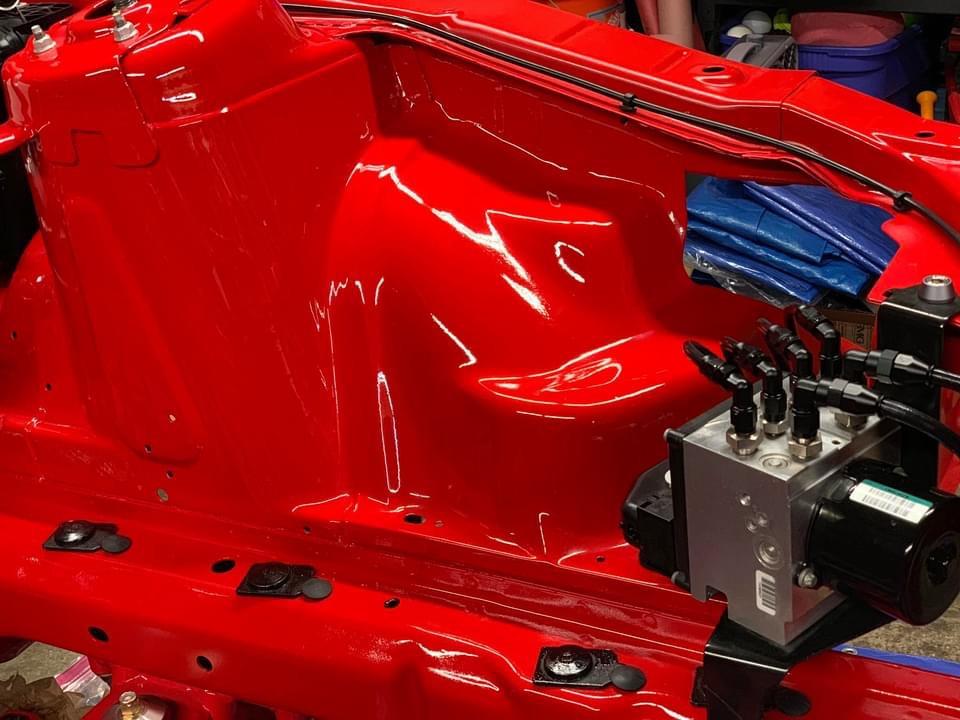

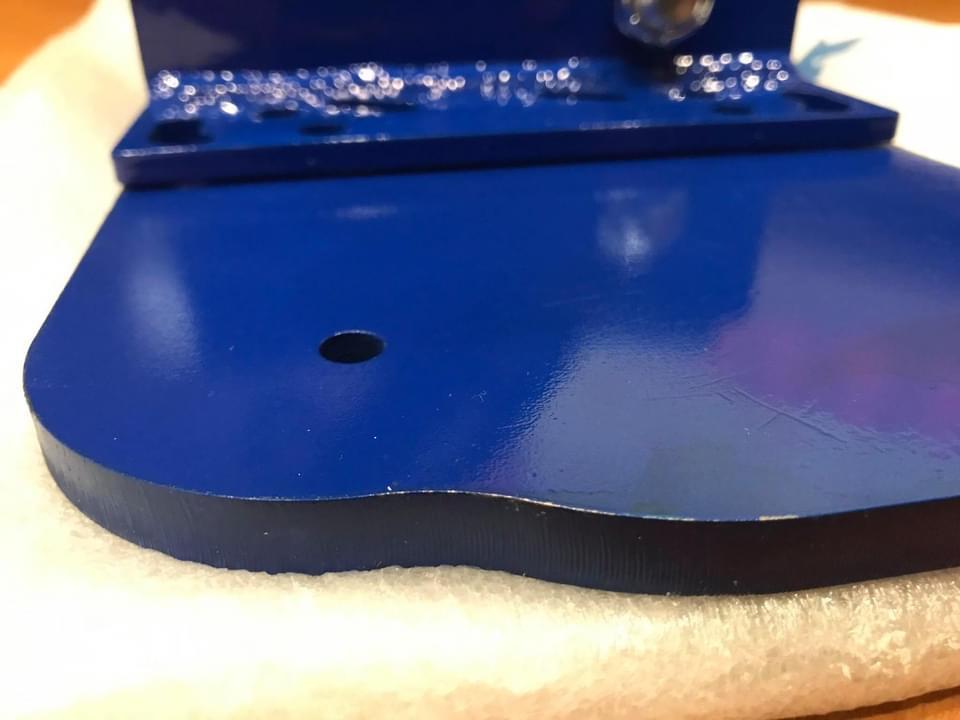

A lot of time went into reconditioning parts I kept. Proper prep and repaint, as well as stripping bolts and black oxide converting them and/or coating in POR15.

The old zinc hardware that was kept was stripped with citric acid, yes, the kind you buy at a grocery store, and if there was any rust, I soaked them in Evapo Rust. Afterward, I used Black Oxide concentrate to quickly convert the surface, then soaked in WD40 extended rust prevention oil. The shafts and heads of the hanger bolts were coated in POR15.

A lot of time went into reconditioning parts I kept. Proper prep and repaint, as well as stripping bolts and black oxide converting them and/or coating in POR15.

The old zinc hardware that was kept was stripped with citric acid, yes, the kind you buy at a grocery store, and if there was any rust, I soaked them in Evapo Rust. Afterward, I used Black Oxide concentrate to quickly convert the surface, then soaked in WD40 extended rust prevention oil. The shafts and heads of the hanger bolts were coated in POR15.