I posted a link to ebay where I purchased the upgraded gt500 intercooler pump. I decided to start a new thread, thinking not everyone is looking at it.

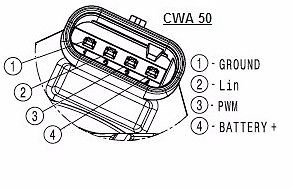

On the ebay listing, the instructions for the newer pumps say to jumper pins 3 and 4 and apply 12v there, and then ground pin1 for the pump to run at full speed.

the harness I bought only utilizes pins 1 and 4.

Can anyone confirm that the pumps indeed run at full speed only when jumpering out 3 and 4 and grounding 1?

here are the links to ebay where the instructions for the pump is

http://www.ebay.com/itm/301868988494?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

this is the jumper I bought, it appears this won't run the pump at full capacity

http://www.ebay.com/itm/222070744960?_trksid=p2055119.m1438.l2649&ssPageName=STRK:MEBIDX:IT

this harness should allow the jumper instead and run the pump at full speed:

http://www.tascaparts.com/oe-ford/cu2z14s411aya

for anyone reading this post, I edited it several times before getting all the information in here. Basically, anyone using the newer pump, if they're only using pins 1 and 4, they probably aren't utilizing the pump at full speed.

can anyone confirm the proper wiring to run the pump at full speed?

On the ebay listing, the instructions for the newer pumps say to jumper pins 3 and 4 and apply 12v there, and then ground pin1 for the pump to run at full speed.

the harness I bought only utilizes pins 1 and 4.

Can anyone confirm that the pumps indeed run at full speed only when jumpering out 3 and 4 and grounding 1?

here are the links to ebay where the instructions for the pump is

http://www.ebay.com/itm/301868988494?_trksid=p2060353.m1438.l2649&ssPageName=STRK:MEBIDX:IT

this is the jumper I bought, it appears this won't run the pump at full capacity

http://www.ebay.com/itm/222070744960?_trksid=p2055119.m1438.l2649&ssPageName=STRK:MEBIDX:IT

this harness should allow the jumper instead and run the pump at full speed:

http://www.tascaparts.com/oe-ford/cu2z14s411aya

for anyone reading this post, I edited it several times before getting all the information in here. Basically, anyone using the newer pump, if they're only using pins 1 and 4, they probably aren't utilizing the pump at full speed.

can anyone confirm the proper wiring to run the pump at full speed?

Attachments

Last edited: