All this is true, but there's only so much twisting you can take out of a chassis that only twists about 0.3°/g to begin with, and the amount of performance benefit that you can extract from a small reduction in that is limited further still.

I have to agree with Norm on this, and I think this is the key. I would not be surprised if the braces increased stiffness, but that doesn't necessarily mean the car will be faster around a track.

To address what you'll probably ask first: No, I have not tried these either, but I'm also skeptical for the same reasons Norm is. I don't have the structural analysis experience he does, but I've been working as a mechanical engineer for almost a decade, and some of my experience has been in race car development. Instead of jumping into the "you don't know if you don't try it" stalemate (which is a logical fallacy, but anyway...), I'll share some of my own experience.

First, I can easily lift up the whole side of my car from anywhere along the frame, and I don't have any kind of aftermarket bracing. I just have stiff springs and a stiffer rear sway bar. I do have a 4-point roll bar that connects the rear shock towers, but I didn't notice any significant difference after installing it. Maybe some chassis bracing would make the other wheel come off the ground faster, but the point is that the S197 chassis is plenty stiff from the factory, and this kind of observation is not a useful indication of rigidity without supporting measurements.

Second, regarding this post:

However I was about 5 mph faster cornering through the Corousel after matrix brace....

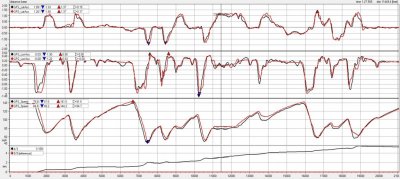

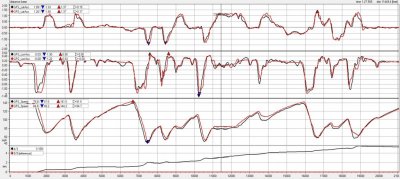

I looked at some old data from when I used to go to Road America, and the only time I gained this much speed in the carousel was after going from NT-01's to R7's:

The R7's were worth ~0.1g (80->85 mph), which is HUGE. In contrast, I've been playing with spring/bar/alignment tuning for years, and I've never seen this much of a change unless I've made the car setup significantly worse. In those cases, I experimented with big changes in lateral load transfer distribution and immediately regretted it. If Norm's figure of 0.3 deg/g is correct, that's about 10 times less than the total roll gradient, so it's extremely unlikely that simple bracing like this could make any measurable difference in LLTD or roll gradient, which ultimately means no measurable difference in grip.

Also, if your hot laps are varying by 2-4 seconds on a 2:00 course, that's actually quite a lot. If you're driving consistently, you should be able to drive well within 1 sec (all else being equal). I'm not trying to be a jerk, but this matters if you're saying the lap time difference is almost entirely attributed to this part.

Taking all of this into consideration, I think the most likely explanation is that your skill also improved a lot after you installed the brace, and that is what dropped your lap times. Maybe it was from experience or maybe it was placebo effect. However, if bracing like this could really drop 2 seconds without any other changes, we would be seeing it used on every serious S197 track car without a full cage. It's pretty common for people to install jacking rails (for that purpose), but I've never heard somebody say they provide a noticeable performance improvement until now.

I appreciate that you're sharing your experience, but unfortunately, it just doesn't make physical sense that you gained 5 mph in the RA carousel and dropped 2 sec from this alone. Maybe we're missing something, but please understand that to us, it seems like you're grasping onto this idea with little evidence to support it. Saying that we won't know if we don't try is not a good argument.