Look, I could be part of the crowd of people "tell you what you want to hear", blow smoke up your backside... but that's not who I am. The reality is: those bolt-on braces and trinkets are good at one thing on the S197 chassis:

adding weight. People like to validate their purchases online, always - this this is just a false portrayal, some self-affirming feeling they need to express to legitimize their choices. This is what 90% of forum comment are based on.

The truth is: there is no data to back up these claims.No scientific testing, just "feelings" and lots of things you can buy.

There are simply a lot of semi-useless parts on the aftermarket made to relieve you of your money. Entire companies are built around this practice. I've heard from some of the folks slinging these parts, after confronting them on their chicanery:

"Well if we didn't make this stuff, someone else would. And their money is green!"

Bolt-on doo-dads promising a "better ride" by giving you a stiffer chassis? Come on... think about it. That's just not how cars work. If the OEM's felt they could improve ride and/or handling with doo-dads, don't you think their multi-billion dollar engineering efforts would uncover these tricks? But some yahoo with a welder... no, HE has it figured out.

We all need to be mindful of the folks slinging miracle parts. Be skeptical, and know that a big portion of this industry only cares about taking your money. You will notice how I am not pushing this OP to any parts we sell in this post. Not a single thing, because what we make is not appropriate for his needs.

The OP is asking for isn't really what the "Corner Carving Racing Tech" sub-forum is about. But I'll attempt to give him useful advice, not validate Bolt On Ballast ideas.

1. The 3500 pound S197 is more similar to an E92 BMW than it is not. We work on lots of both of these cars, and I've driven many dozens examples of each. What he is missing is more likely tied to an a tire and wheel difference than anything else. The OEM tires on the S197 are SUPER tall sidewall Mud and Snow rated garbage. The OEM tires on somehting like an E92 M3 are orders of magnitude better.

NOTHING we do to our cars makes more of a difference in PERFORMANCE and RIDE than the tires we outfit them with. NOT. ONE. THING.

Upgrade to better rolling stock to get what you are looking after, not steel ding-dongs and tubular braces.

2. Tramlining is 75% caused by alignment, probably 25% cause by tires. Take out any front toe (zero) and put new/name brand tires on and inflate them to proper pressures and that all likely goes away.

3. If you want a good ride for "street driving" don't buy any of the cheap coilovers or shocks out there. Get something OEM appropriate, new, and hopefully monotube based. Bilstein, if you can find them, might be a good place to start.

Good luck - and STAY SKEPTICAL,

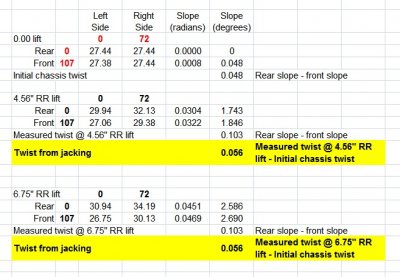

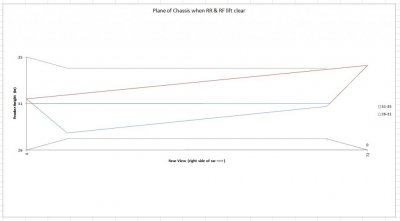

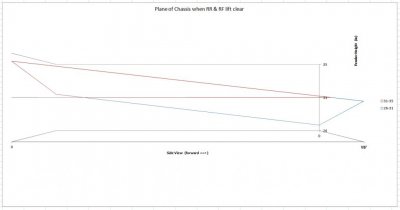

I also took a crack at displaying the presence or absence of chassis twist. Within the limits of accuracy of my measurements (I do question a couple of them) and the ability of Excel to display a surface chart, there isn't much. You'd be looking for the front and rear lines in rear view and the right side and left side lines in side view to not be parallel to each other if the chassis was twisting enough to measure to within about 1/32".

I also took a crack at displaying the presence or absence of chassis twist. Within the limits of accuracy of my measurements (I do question a couple of them) and the ability of Excel to display a surface chart, there isn't much. You'd be looking for the front and rear lines in rear view and the right side and left side lines in side view to not be parallel to each other if the chassis was twisting enough to measure to within about 1/32".