07 procharger

Addicted to modding

If your nitrous A/F mixture is rich you would lower the size of the fuel jet. For the avg street nitrous (up to 150hp) user I suggest tuning to 11.8 or so on a wideband.

As a side note, rich is not "safe"...the correct A/F ratio is "safe"

I am running an intank 255lph pump with a second inline 255lph pump feeding through an Aeromotive EFI regulator set to 45psi. The nitrous system feeds off of a 1 gal cell that has its own 255lph pump and regulator set currently at 11.5psi.

To adjust nitrous A/F ratio I either change the fuel jet or adjust the flowing fuel pressure of the low pressure fuel system.

before i headed out to dyno tune the nitrous i spoke to brenspeed and they recomended to keep the a/f between 10.5 and 11.0 on the bottle.currently im at 11.1 at wot.i try going from 34 to 32 on the fuel and it tipped at 11.5 a/f and gain 1rwhp and 2rwtq.didnt think it was worth it so i went back to the 34.

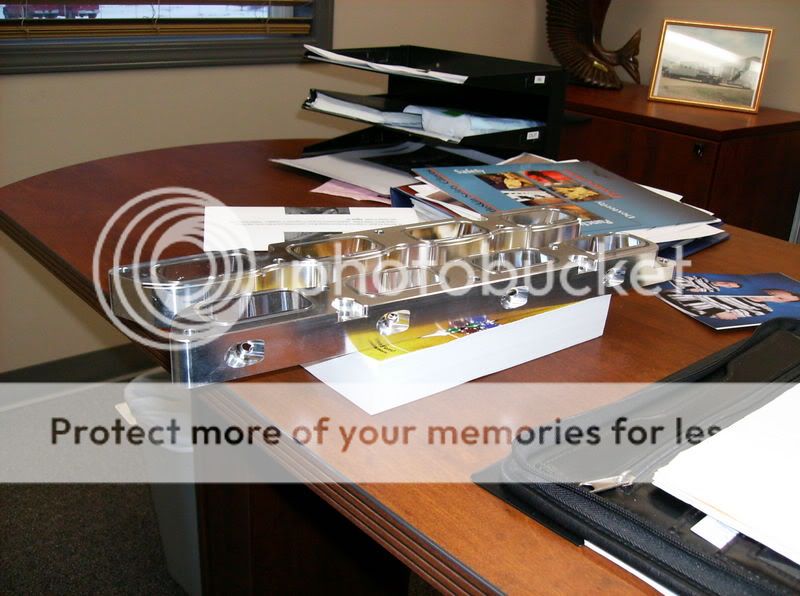

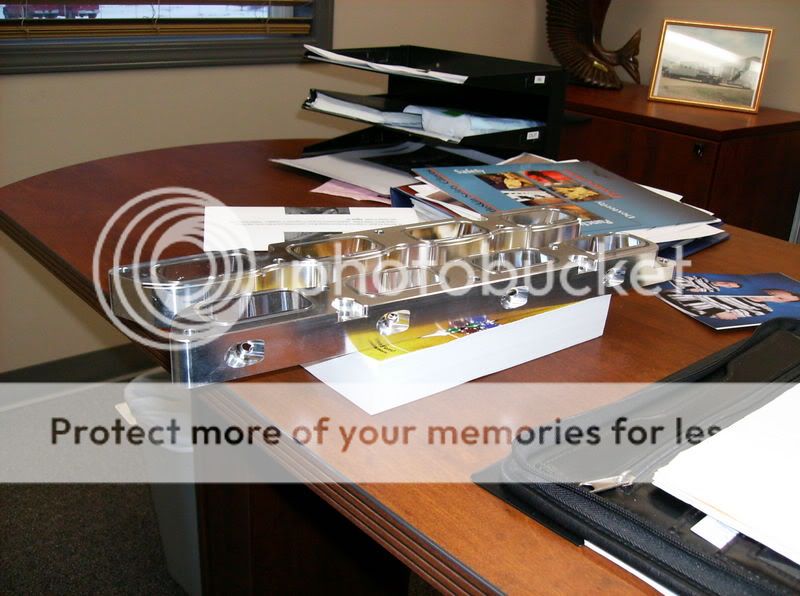

If I am looking at this correctly, the plates are not "plumbed" for nitrous, but are pre-drilled and tapped to accept nozzles for a direct port

Yea ! Who makes that shit ?

Shit is real! Right !wow, that looks insane! I know what im going to set up when im ready to run numbers

If your nitrous A/F mixture is rich you would lower the size of the fuel jet. For the avg street nitrous (up to 150hp) user I suggest tuning to 11.8 or so on a wideband.

As a side note, rich is not "safe"...the correct A/F ratio is "safe"

wow, that looks insane! I know what im going to set up when im ready to run numbers

looks like a tuning nightmare to me....but is a great idea.

Imagine doing jet changes on that setup and you will see what I mean.

ya its a bit of work, but the payoff is a nice stealthy install in the end.

ya its a bit of work, but the payoff is a nice stealthy install in the end.