You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kennebell 2.6L low boost

- Thread starter teeje

- Start date

I made the intake out of 4" round alum. 3.5 top, 10% of bottom

Gotcha. I might do that I work on heavy machinery so I can get that tubing all day for the price of free. So the 3.5 pulley will be good you think? I’ll definitely keep you guys posted. So far it’s been great just with that base tune. I got scared at first when I revved it up when I heard that loud whooshing sound. Sent it over to mike at kennebell (the video I posted above) and he said that’s normal. I’m wondering if your guys’ blower does the same type of noise?

Sent from my iPhone using Tapatalk

3.5" and stock crank pulley should put you at about 9 psi at 6000 rpm. You just need to make sure you are not maxxing out the fuel pump or going lean for some other reason. If its a stock block, I would not rev more than 6200 rpm. Keep 91 or 93 octane in it and you'll be fine.

And yes, your video sounds fine to me. 2.6 liters is a fairly big blower for a 4.6 liter motor. Plus the blower is always pumping air and with the motor unloaded most of that air is going thru the bypass valve which is not that big of an area. My point is that there is a lot of air moving around and that makes some noise.The kb is well engineered and seldom has any issues.

And yes, your video sounds fine to me. 2.6 liters is a fairly big blower for a 4.6 liter motor. Plus the blower is always pumping air and with the motor unloaded most of that air is going thru the bypass valve which is not that big of an area. My point is that there is a lot of air moving around and that makes some noise.The kb is well engineered and seldom has any issues.

Last edited:

3.5" and stock crank pulley should put you at about 9 psi at 6000 rpm. You just need to make sure you are not maxxing out the fuel pump or going lean for some other reason. If its a stock block, I would not rev more than 6200 rpm. Keep 91 or 93 octane in it and you'll be fine.

And yes, your video sounds fine to me. 2.6 liters is a fairly big blower for a 4.6 liter motor. Plus the blower is always pumping air and with the motor unloaded most of that air is going thru the bypass valve which is not that big of an area. My point is that there is a lot of air moving around and that makes some noise.The kb is well engineered and seldom has any issues.

Thank you. And yeah 93 all the time every time nothing less. Very fortunate to have 93 everywhere here

Sent from my iPhone using Tapatalk

Guessing it was boost loss from the intercooler.

Elaborate on that please. How can a normally functioning intercooler cause am”boost loss”?

I don't know the science behind it but I've heard about it in many places. My only guess is the heat exchanger causes boost loss because it is a slight restriction so after the exchanger the boost pressure in the manifold is lower than it is before the exchanger? Idk. Not saying that for sure but that's my only thought right now.

Sent from my SM-N950U1 using Tapatalk

Sent from my SM-N950U1 using Tapatalk

Midlife Crises

Senior Member

If the intercooler cools the air, the air will condense and be at a lower pressure if it occupies the same space.Elaborate on that please. How can a normally functioning intercooler cause am”boost loss”?

The cool “ha,ha,ha” thing is the air ( more dance extra oxygen) is still there at a lower temperature. You can add more (smaller blower pulley) and get back up to Your boost limit.

Last edited:

There is no significant boost lost from the intercooler. Your pulley sizes and boost numbers for the stated rpms all seem normal. This is just how it works. KB likes to run a lot of timing and lower boost to make power. Pretty much the rest of the world runs less timing and higher boost. So your original stock KB pulley is going to end up with low boost. This is just the way it is.

don't equate loss with reduction... they are not the same

I'm not trying to split hairs. OP seems to think that there is or was a problem. I'm simply saying that the numbers stated are completely inline with what I've personally seen. I've had the same 2.6L KB for 10 years now including 3 different pulleys and 2 different crank pulleys (stock and +10% IW).

My comment above was not directed at you in particularI'm not trying to split hairs. OP seems to think that there is or was a problem. I'm simply saying that the numbers stated are completely inline with what I've personally seen. I've had the same 2.6L KB for 10 years now including 3 different pulleys and 2 different crank pulleys (stock and +10% IW).

Well very bad news. Went on a second datalog. Maybe saw 5000 maybe 5500 rpm and the blower seized...gonna call kb tomorrow

Well that just sucks! I’m sorry to hear that. How many miles on the blower?

EDIT:

Looking back to the original post (to refresh my memory) I see this is a fairly recent install. Hopefully KB offers a warranty period and this will be covered.

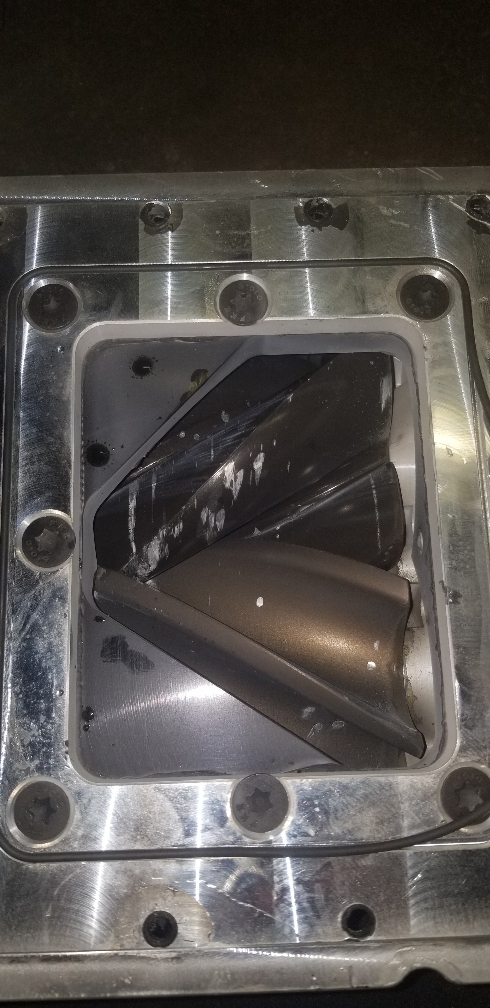

Maybe what .10? I'm not even joking... I took the head unit off and there was shreds all on top of the heat exchanger. Thank god it didnt go into the engine. The screws are all screwed up too..lol no pun intendedWell that just sucks! I’m sorry to hear that. How many miles on the blower?

Sent from my SM-N950U1 using Tapatalk

Maybe what .10? I'm not even joking... I took the head unit off and there was shreds all on top of the heat exchanger. Thank god it didnt go into the engine. The screws are all screwed up too..lol no pun intended

Damnit! I hate that crap. I really feel your pain, I’d be pretty upset myself. I truly hope they will just replace this thing without a bunch of hassles.

When you get a chance, upload some pics.

Here ya goDamnit! I hate that crap. I really feel your pain, I’d be pretty upset myself. I truly hope they will just replace this thing without a bunch of hassles.

When you get a chance, upload some pics.

Sent from my SM-N950U1 using Tapatalk

That’s pretty severe for no miles. Is there any possibility something got pulled into the intake tube and caused this, or do you think it was a material defect?

I know that with Whipple and Edelbrock, they require that you package it all up, and ship it to them for disassembly to determine if they will take the hit. They seldom do, and usually blame the installer.

I had my Roush system installed at an authorized dealer/service center to avoid issues like this. I saved up a long time to go FI, and wanted a safety net since reading horror stories of EXACTLY this type of failure on both Whipple / Edelbrock.

You just experienced my nightmare. I know you’re a young guy, and a Vet. I really hate to see crap like this. Damned Empathy... Sometimes I just have too much of it for fellow Vets.

I know that with Whipple and Edelbrock, they require that you package it all up, and ship it to them for disassembly to determine if they will take the hit. They seldom do, and usually blame the installer.

I had my Roush system installed at an authorized dealer/service center to avoid issues like this. I saved up a long time to go FI, and wanted a safety net since reading horror stories of EXACTLY this type of failure on both Whipple / Edelbrock.

You just experienced my nightmare. I know you’re a young guy, and a Vet. I really hate to see crap like this. Damned Empathy... Sometimes I just have too much of it for fellow Vets.

Last edited:

I think material defect because I've done 3 pulls for my datalog and they were all fine..That’s pretty severe for no miles. Is there any possibility something got pulled into the intake tube and caused this, or do you think it was a material defect?

Sent from my SM-N950U1 using Tapatalk

Similar threads

- Replies

- 10

- Views

- 1K

- Replies

- 4

- Views

- 550

- Replies

- 8

- Views

- 1K

Support us!

Support Us - Become A Supporting Member Today!

Click Here For Details