Mineral_'01

forum member

- Joined

- Aug 24, 2014

- Posts

- 183

- Reaction score

- 1

You guys should probably have a look at this if you haven't already seen it. Very interesting, I sense a possible SLA suspension setup in addition to their new K-member.

A lot more pictures and info here:

http://www.svtperformance.com/forums/showthread.php?1039173-Maximum-Motorsports-K-Member

I'm allowed to post links to other forums right?

Edit, new info released from maximum. Taken from the thread above:

Maximum could have made it weaker if they wanted to. Thankfully, they didn't. There are any number out there that you can twirl on your finger if that's what you're after.

Here's a breakdown they were generous enough to provide in advance of release. Thanks again Chuck, Luka, Jack, and everyone else at Maximum!

Design Goals

When it comes to the k-member, we feel that improved geometry and strength/stiffness are head and shoulders above all other considerations. For the S197 k-member we put not increasing NVH at the secondary level. Reducing weight comes last because it is nearly impossible to reduce weight without also reducing strength and stiffness. Since the k-member supports the entire front suspension while also holding up the engine, we feel that simply in the interest of safety we need to maintain a particular level of strength. If one is serious about weight reduction, we feel it should be done by reducing the weight of something that is not a mission-critical part, as the k-member is. Fiberglass or carbon fiber body panels are our first choice. This does not mean that we ignore weight-saving, as one can readily see from the lightening holes in the k-member. We do what we can, as long as we are maintaining our desired strength and stiffness.

This k-member is not aimed at drag racers who want to save weight at any cost. We know the majority of our customers are using their vehicle on the street, with occasional track events. Durability and low NVH are their primary concerns. Most of our Fox/SN95 parts were designed for street driving, and then tested and proven on racecars. We followed the same path when we designed this k-member.

Strength/Stiffness

With the S197 strut suspension design, most of the cornering loads are fed into the forward control arm pivots on the k-member. The highest loads at the rearward control arm pivot mounts of the k-member are during heavy braking. We focused on making the section forward of the rear pivots stiffer than the stock k-member. We also concentrated on feeding those loads primarily through the upper frame rails.

We built two fixtures to load test the k-members. The MM k-member deflected 30% less than the stock k-member during a simulated cornering load. We tested one aftermarket k-member, and it deflected 40% more than the stock k-member did in the same test scenario.

NVH

NVH is increased by using non-stock motor mounts. Many people complain of excessive vibration, especially at ide, when using urethane motor mounts. Some NVH comes from non-stock FCA bushings. These cause more of an increase in impact harshness than vibration. NVH is certainly subjective. What one person finds acceptable for daily driving another considers intolerable. In our opinion, the S197 is far less tolerant of changes that affect NVH than the previous generation. Bushing changes that cause unnoticeable or minor increases in NVH on a Fox/SN95 chassis cause big NVH increases with the S197 chassis.

Motor Mounts

Over the past several years we heard many complaints from people about increased NVH, primarily caused by the proprietary urethane motor mounts used in their aftermarket S197 k-member, regardless of the manufacturer. We also heard from our dealers, and other installers, who disliked having their customers complain about increased NVH after installing a k-member.

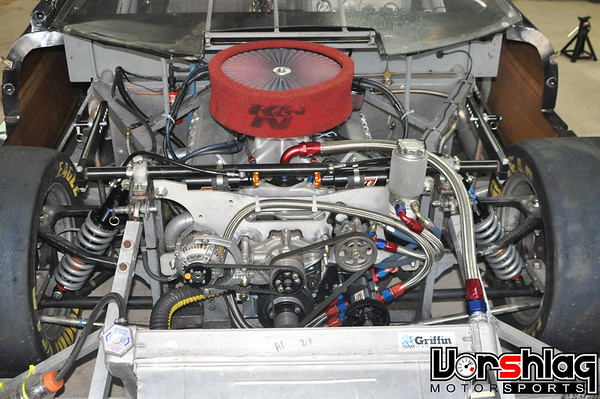

Through the building of a couple of iterations of our first design, one of which is on the yellow Vortech SEMA car, we encountered many design issues trying to route tubes around the stock motor mounts while also offering two control arm mounting heights. When MM’s head design engineer, Luka, had the idea to make machined aluminum blocks to lower the top mounting flange of the k-member, those difficulties went away. As a bonus, by mounting the motor mounts to the aluminum blocks, the engine could stay in its stock location even when the rest of the k-member was removed. That greatly improves access for maintenance and header installation.

Aluminum Blocks

Each aluminum block is aligned to the frame rail with a close-fitting pin that fits into the same hole in the frame rail that Ford used for alignment on the assembly line.

The k-member mounting flange has over-sized holes to allow shifting it relative to the blocks, allowing precise squaring because it can move more than the stock k-member can. In the event that even more movement is needed, the pins can be easily removed from the aluminum blocks to allow shifting the blocks on the frame rails.

The blocks were designed to place the top of the k-member below the pinch weld on the underside of the frame rails. This lower position allows the k-member to be adjusted without running into the pinch welds.

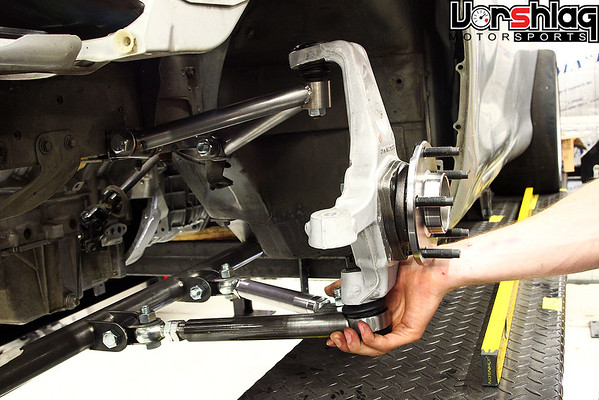

Yet another bonus: The blocks were designed to provide an accurate mounting point for the upper control arm of an SLA suspension. We are still in the testing stages of our design and have no planned release date.

FCA Height

We did not send Tob spacers for the rearmost front control arm mounts because we knew he would not be using the upper set of holes. For extreme lowering, when moving the FCAs to the upper set of holes would be beneficial, several things are required. Spacers are needed to move the rearmost FCA mount upwards to match the front mount. The stock rearward FCA bushing must be replaced because its large diameter would interfere with the frame rail; smaller diameter aftermarket bushings of either Delrin or urethane are required. Bumpsteer must be addressed by installing a bolt-through bumpsteer kit. The stronger bolt-through style is required instead of the tapered stud to prevent breakage from the increased load from the extra leverage of the greater length required to properly locate the outer tie-rod end to match the FCA in the upper set of holes.

Anti-dive

We did not alter the angle of the FCA pivot axis because we did not want to significantly change the stock anti-dive percentage. The act of lowering an S197 will cause an increase in anti-dive. With the stock k-member, lowering the car one inch increases anti-dive from about 15% to about 20%. With this MM k-member, lowering one inch with the FCAs in the lower set of holes also increases anti-dive to about 20%.

We learned 15 years ago through testing that significantly increasing the anti-dive of the Mustang strut suspension caused a bad effect that far outweighed any beneficial effects: Encountering even small bumps during heavy braking would easily cause front wheel lock up.

There are two main reasons why increased anti-dive worsens braking on an S197 chassis. First, and this applies to all cars, as anti-dive is increased the resulting suspension geometry causes the tire to move more forward with bump travel. This makes the slope of the bump steeper, increasing the vertical acceleration of the tire, bouncing it off of the ground. Second, the geometry required for increased anti-dive increases the bending load on the strut. This increases friction in the strut, causing poor compliance of the tire to the road. This second problem is missing from an SLA front suspension because it does not have a strut.

Bumpsteer

A bumpsteer kit is required with the MM k-member. The stock front suspension has the usual Ford design of a small amount of bumpsteer (toe-out under compression) to promote understeer. Raising the inner FCA pivot points requires changing either the inner or outer tie-rod pivot points to match, just to maintain the stock bumpsteer (toe-change). The easiest way to do this is to use a bumpsteer kit at the outer tie-rod end.

Front Control Arms

We are not in a hurry to make our own. The 2010-14 Ford arms, with the larger ball joints, are very robust. A lighter weight arm would likely not be as strong and stiff.

Floorpan Distortion

Until this thread we had not heard of floorpan distortion at the rearward mount caused by anything other than incorrectly jacking up the car at that point. We also have not seen any permanent floorpan deformation on any of our test cars, driven both on the street and on track.

We knew of the k-member rear leg failure shown in a photo posted in this thread, and designed a strengthening brace for the rear k-member mount. We did not include it on the first pilot run of k-members because it would have added 2-3 lb. We are still discussing making it an option; not choosing it would still add weight, but well under 0.5 lb.

Steering Vibrations

The advent of the electric rack in 2011 brought both good and bad. The stock EPAS anti-nibble programming was based on the stiffness of the stock rubber FCA bushings. Replacing those bushings with stiffer urethane or Delrin causes the feedback loop in the anti-nibble programming to become unstable, causing the system to oscillate. These oscillations are felt in the steering wheel as vibrations. By allowing the use of the stock control arm bushings, we are able to minimize any EPAS steering related issues until a solution cheaper than upgrading the rack can be found.

Material

All tubes are mild steel DOM tubing. The main tubes, on the lower plane, are 1.75” diameter with a 0.095” wall thickness.

The Envelope

We maintained the same ground plane as the stock k-member. The other tubes are located to provide more clearance towards the engine, exhaust, etc., than does the stock k-member.

Weight

Yes, it is heavier than a stock k-member; 42.54 lb vs. 40.52 lb. We tried, but upon meeting our design goals, this is where it is. Handling is improved. Stability and predictability are improved; the front end feels much more… Planted is the best word for it. There is less front-end drama when cornering. Maintenance and header installation is greatly improved. Someday an easy SLA upgrade will be possible.

Radiator Core Support

We have finalized the design. Production fixtures will be built once the k-member is steadily rolling off the line. It is a fair bit lighter than the stock core support. Provision for a stock-location swaybar mount is an option, as well as mounting points for a splitter.

Forward Braces

These connect the MM core support to the MM k-member. They add stiffness to the front end. The swaybar mounts are located on the braces. The braces include a provision for shifting the swaybar pivots fore/aft to better align the end links on adjustable front swaybars. The design is not finalized.

Engine Support Beam

We’ve designed a reasonably cheap tool to greatly aid in the installation of the k-member. When using an engine hoist to support the engine during k-member removal, the legs block access to the underside of the vehicle. Our engine support beam spans the strut towers and uses ratchet straps to temporarily suspend the engine while the k-member is swapped.

Availability

Mid-November. The design is finalized, except for perhaps adding the option for the rear mount area brace.

Pricing

Still TBD. Should be finalized within two weeks.

A lot more pictures and info here:

http://www.svtperformance.com/forums/showthread.php?1039173-Maximum-Motorsports-K-Member

I'm allowed to post links to other forums right?

Edit, new info released from maximum. Taken from the thread above:

Maximum could have made it weaker if they wanted to. Thankfully, they didn't. There are any number out there that you can twirl on your finger if that's what you're after.

Here's a breakdown they were generous enough to provide in advance of release. Thanks again Chuck, Luka, Jack, and everyone else at Maximum!

Design Goals

When it comes to the k-member, we feel that improved geometry and strength/stiffness are head and shoulders above all other considerations. For the S197 k-member we put not increasing NVH at the secondary level. Reducing weight comes last because it is nearly impossible to reduce weight without also reducing strength and stiffness. Since the k-member supports the entire front suspension while also holding up the engine, we feel that simply in the interest of safety we need to maintain a particular level of strength. If one is serious about weight reduction, we feel it should be done by reducing the weight of something that is not a mission-critical part, as the k-member is. Fiberglass or carbon fiber body panels are our first choice. This does not mean that we ignore weight-saving, as one can readily see from the lightening holes in the k-member. We do what we can, as long as we are maintaining our desired strength and stiffness.

This k-member is not aimed at drag racers who want to save weight at any cost. We know the majority of our customers are using their vehicle on the street, with occasional track events. Durability and low NVH are their primary concerns. Most of our Fox/SN95 parts were designed for street driving, and then tested and proven on racecars. We followed the same path when we designed this k-member.

Strength/Stiffness

With the S197 strut suspension design, most of the cornering loads are fed into the forward control arm pivots on the k-member. The highest loads at the rearward control arm pivot mounts of the k-member are during heavy braking. We focused on making the section forward of the rear pivots stiffer than the stock k-member. We also concentrated on feeding those loads primarily through the upper frame rails.

We built two fixtures to load test the k-members. The MM k-member deflected 30% less than the stock k-member during a simulated cornering load. We tested one aftermarket k-member, and it deflected 40% more than the stock k-member did in the same test scenario.

NVH

NVH is increased by using non-stock motor mounts. Many people complain of excessive vibration, especially at ide, when using urethane motor mounts. Some NVH comes from non-stock FCA bushings. These cause more of an increase in impact harshness than vibration. NVH is certainly subjective. What one person finds acceptable for daily driving another considers intolerable. In our opinion, the S197 is far less tolerant of changes that affect NVH than the previous generation. Bushing changes that cause unnoticeable or minor increases in NVH on a Fox/SN95 chassis cause big NVH increases with the S197 chassis.

Motor Mounts

Over the past several years we heard many complaints from people about increased NVH, primarily caused by the proprietary urethane motor mounts used in their aftermarket S197 k-member, regardless of the manufacturer. We also heard from our dealers, and other installers, who disliked having their customers complain about increased NVH after installing a k-member.

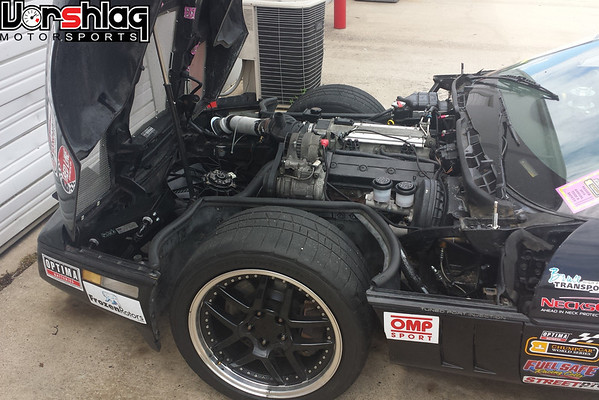

Through the building of a couple of iterations of our first design, one of which is on the yellow Vortech SEMA car, we encountered many design issues trying to route tubes around the stock motor mounts while also offering two control arm mounting heights. When MM’s head design engineer, Luka, had the idea to make machined aluminum blocks to lower the top mounting flange of the k-member, those difficulties went away. As a bonus, by mounting the motor mounts to the aluminum blocks, the engine could stay in its stock location even when the rest of the k-member was removed. That greatly improves access for maintenance and header installation.

Aluminum Blocks

Each aluminum block is aligned to the frame rail with a close-fitting pin that fits into the same hole in the frame rail that Ford used for alignment on the assembly line.

The k-member mounting flange has over-sized holes to allow shifting it relative to the blocks, allowing precise squaring because it can move more than the stock k-member can. In the event that even more movement is needed, the pins can be easily removed from the aluminum blocks to allow shifting the blocks on the frame rails.

The blocks were designed to place the top of the k-member below the pinch weld on the underside of the frame rails. This lower position allows the k-member to be adjusted without running into the pinch welds.

Yet another bonus: The blocks were designed to provide an accurate mounting point for the upper control arm of an SLA suspension. We are still in the testing stages of our design and have no planned release date.

FCA Height

We did not send Tob spacers for the rearmost front control arm mounts because we knew he would not be using the upper set of holes. For extreme lowering, when moving the FCAs to the upper set of holes would be beneficial, several things are required. Spacers are needed to move the rearmost FCA mount upwards to match the front mount. The stock rearward FCA bushing must be replaced because its large diameter would interfere with the frame rail; smaller diameter aftermarket bushings of either Delrin or urethane are required. Bumpsteer must be addressed by installing a bolt-through bumpsteer kit. The stronger bolt-through style is required instead of the tapered stud to prevent breakage from the increased load from the extra leverage of the greater length required to properly locate the outer tie-rod end to match the FCA in the upper set of holes.

Anti-dive

We did not alter the angle of the FCA pivot axis because we did not want to significantly change the stock anti-dive percentage. The act of lowering an S197 will cause an increase in anti-dive. With the stock k-member, lowering the car one inch increases anti-dive from about 15% to about 20%. With this MM k-member, lowering one inch with the FCAs in the lower set of holes also increases anti-dive to about 20%.

We learned 15 years ago through testing that significantly increasing the anti-dive of the Mustang strut suspension caused a bad effect that far outweighed any beneficial effects: Encountering even small bumps during heavy braking would easily cause front wheel lock up.

There are two main reasons why increased anti-dive worsens braking on an S197 chassis. First, and this applies to all cars, as anti-dive is increased the resulting suspension geometry causes the tire to move more forward with bump travel. This makes the slope of the bump steeper, increasing the vertical acceleration of the tire, bouncing it off of the ground. Second, the geometry required for increased anti-dive increases the bending load on the strut. This increases friction in the strut, causing poor compliance of the tire to the road. This second problem is missing from an SLA front suspension because it does not have a strut.

Bumpsteer

A bumpsteer kit is required with the MM k-member. The stock front suspension has the usual Ford design of a small amount of bumpsteer (toe-out under compression) to promote understeer. Raising the inner FCA pivot points requires changing either the inner or outer tie-rod pivot points to match, just to maintain the stock bumpsteer (toe-change). The easiest way to do this is to use a bumpsteer kit at the outer tie-rod end.

Front Control Arms

We are not in a hurry to make our own. The 2010-14 Ford arms, with the larger ball joints, are very robust. A lighter weight arm would likely not be as strong and stiff.

Floorpan Distortion

Until this thread we had not heard of floorpan distortion at the rearward mount caused by anything other than incorrectly jacking up the car at that point. We also have not seen any permanent floorpan deformation on any of our test cars, driven both on the street and on track.

We knew of the k-member rear leg failure shown in a photo posted in this thread, and designed a strengthening brace for the rear k-member mount. We did not include it on the first pilot run of k-members because it would have added 2-3 lb. We are still discussing making it an option; not choosing it would still add weight, but well under 0.5 lb.

Steering Vibrations

The advent of the electric rack in 2011 brought both good and bad. The stock EPAS anti-nibble programming was based on the stiffness of the stock rubber FCA bushings. Replacing those bushings with stiffer urethane or Delrin causes the feedback loop in the anti-nibble programming to become unstable, causing the system to oscillate. These oscillations are felt in the steering wheel as vibrations. By allowing the use of the stock control arm bushings, we are able to minimize any EPAS steering related issues until a solution cheaper than upgrading the rack can be found.

Material

All tubes are mild steel DOM tubing. The main tubes, on the lower plane, are 1.75” diameter with a 0.095” wall thickness.

The Envelope

We maintained the same ground plane as the stock k-member. The other tubes are located to provide more clearance towards the engine, exhaust, etc., than does the stock k-member.

Weight

Yes, it is heavier than a stock k-member; 42.54 lb vs. 40.52 lb. We tried, but upon meeting our design goals, this is where it is. Handling is improved. Stability and predictability are improved; the front end feels much more… Planted is the best word for it. There is less front-end drama when cornering. Maintenance and header installation is greatly improved. Someday an easy SLA upgrade will be possible.

Radiator Core Support

We have finalized the design. Production fixtures will be built once the k-member is steadily rolling off the line. It is a fair bit lighter than the stock core support. Provision for a stock-location swaybar mount is an option, as well as mounting points for a splitter.

Forward Braces

These connect the MM core support to the MM k-member. They add stiffness to the front end. The swaybar mounts are located on the braces. The braces include a provision for shifting the swaybar pivots fore/aft to better align the end links on adjustable front swaybars. The design is not finalized.

Engine Support Beam

We’ve designed a reasonably cheap tool to greatly aid in the installation of the k-member. When using an engine hoist to support the engine during k-member removal, the legs block access to the underside of the vehicle. Our engine support beam spans the strut towers and uses ratchet straps to temporarily suspend the engine while the k-member is swapped.

Availability

Mid-November. The design is finalized, except for perhaps adding the option for the rear mount area brace.

Pricing

Still TBD. Should be finalized within two weeks.

Last edited: