Department Of Boost

Alpha Geek

- Joined

- May 26, 2010

- Posts

- 8,809

- Reaction score

- 28

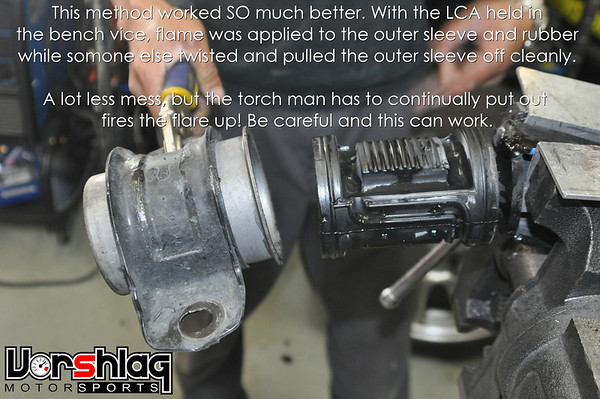

Basically you can get the outer shell off easy enough. Then you need a 3" cutting disc (and a mask and gloves and glasses and a jumpsuit and a well ventilated area and probably a plastic sheet to make things easier to clean up) after you've cut through the bushing and the inner sleeve a bit, you can use an air chisel to spread it apart and come off. I spent the better part of a day doing just one arm.

Don't forget, you need these guys too!