EXACTLY!!! A mix and match for sure.It depends on what car you have. For Mustangs with manual transmissions:

3.31s were standard on 2011-2014 (S197) & 2015-2017 (S550) Mustang GTs.

3.73s were an option on 2011-2017 GTs and standard on the Track Pack, BOSS, Shelby, and Performance Pack Cars.

3.73s were standard on 2018+ Mustangs.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Good article regarding the S197 as a track car

- Thread starter RavenGT

- Start date

Norm Peterson

corner barstool sitter

Billy is talking about road course cars/build-ups here. It's different from drag racing in a number of ways.If that is the case then 3:31s rears in the 2014 Mustang are the same as 3:73 rears in the 2018 Mustang with an over all ratio for both as 12 to 1. I can see why the 10 speed auto with a very steep 1st gear and 3:55 would feel very strong and might get into the very high 11s.

For road course work you have to look deeper than just 60-foot times, ETs, and overall ratios in 1st gear. At least when you have 6 gears (or more) to play with.

Evidently, Ford revised their MT gearing philosophy when they went to the D4 iteration of the MT82. I'm not at all sure why, but in any event the number of numerically overdrive ratios there might be is mostly irrelevant to road course driving (there might be a tiny power-transfer efficiency matter depending on what any overdrive ratio might specifically be).

The original MT82 gearing looks a lot like that of the close ratio gearboxes of the 1960s, plus a sort-of granny gear 1st to satisfy the dragstrip crowd and a way-tall overdrive ratio to satisfy highway mpg requirements.

The D4 iteration tightens up the spacing from 4th to 6th at the expense of having wider spacing from 1st to 4th. Unless you gear the axle unusually short, you're likely to be wasting the tightness of the upper gears while having to live with wider gear spacing down where you're more likely to be driving.

Norm

Last edited:

Norm Peterson

corner barstool sitter

That 4.33 (4.30?) was strictly for drag racing . . . but yeah, 1st gear ratios in the mid-twos did need help.

IIRC 3.55 and 3.91 were more normal production fitments.

Norm

IIRC 3.55 and 3.91 were more normal production fitments.

Norm

Norm Peterson

corner barstool sitter

I ran a few numbers and it looks like BillyJ's suspension tuning isn't a whole lot different from what I ended up with. The balance of TLLTD is within 1% and roll/g looks to be within about 0.2°/g.

I'm using slightly more spring, comparable front bar, slightly less rear bar, less lowering but no so far that any roll center/bumpsteer correction was indicated.

It's a pretty darn good place to be, so this is one time where I'd make the easy recommendation to just follow somebody else's lead instead of piecing your own kit together from multiple sources.

Norm

I'm using slightly more spring, comparable front bar, slightly less rear bar, less lowering but no so far that any roll center/bumpsteer correction was indicated.

It's a pretty darn good place to be, so this is one time where I'd make the easy recommendation to just follow somebody else's lead instead of piecing your own kit together from multiple sources.

Norm

GlassTop09

Senior Member

Hi BillyJRacing,Hey guys, I wanted to update this thread with the links of all of the articles thus far.

I just started this project on MotoIQ to take my experience and background racing the S197 Mustang platform professionally over the past 10 years in Grand-Am, and as a development driver who worked with Ford on the GT350, GT500 and Ford GT (among other Mustang variants) to recommend how to make an inexpensive, powerful, great handling and fun to drive track car. Stay tuned for some insight on the car, what's important to upgrade and what isn't necessary or even detrimental to change. Enjoy:

Part 1: INTRO

"More people need to consider the (2005-2014) “S197” Mustang for track use! Parts are cheap and it really does not take much to turn one into an awesome “Driver’s-car”. There are a lot of misconceptions that Mustangs don’t handle well, are too heavy, and only belong on the drag strip. This project car is focused on dispelling these myths and show how to make arguably the best and least expensive 400whp track car."

[/URL]

Project Budget 400WHP S197 Mustang Track Car: Part 2 – Finding out what it takes to make 400WHP

"We strap our first-generation 5.0L “Coyote” V8-powered S197 Mustang to the dyno and test the 2018+ “Gen-3” intake manifold, K&N air intake, and tunes by Palm Beach Dyno to find out the least expensive way to make 400 WHP on pump gas. "

[/URL]

In the article:

-Baseline dyno

-Dyno K&N Performance Cold Air Intake

-Dyno 2018 "Gen3" intake manifold

-Dyno Tune by Palm Beach Dyno

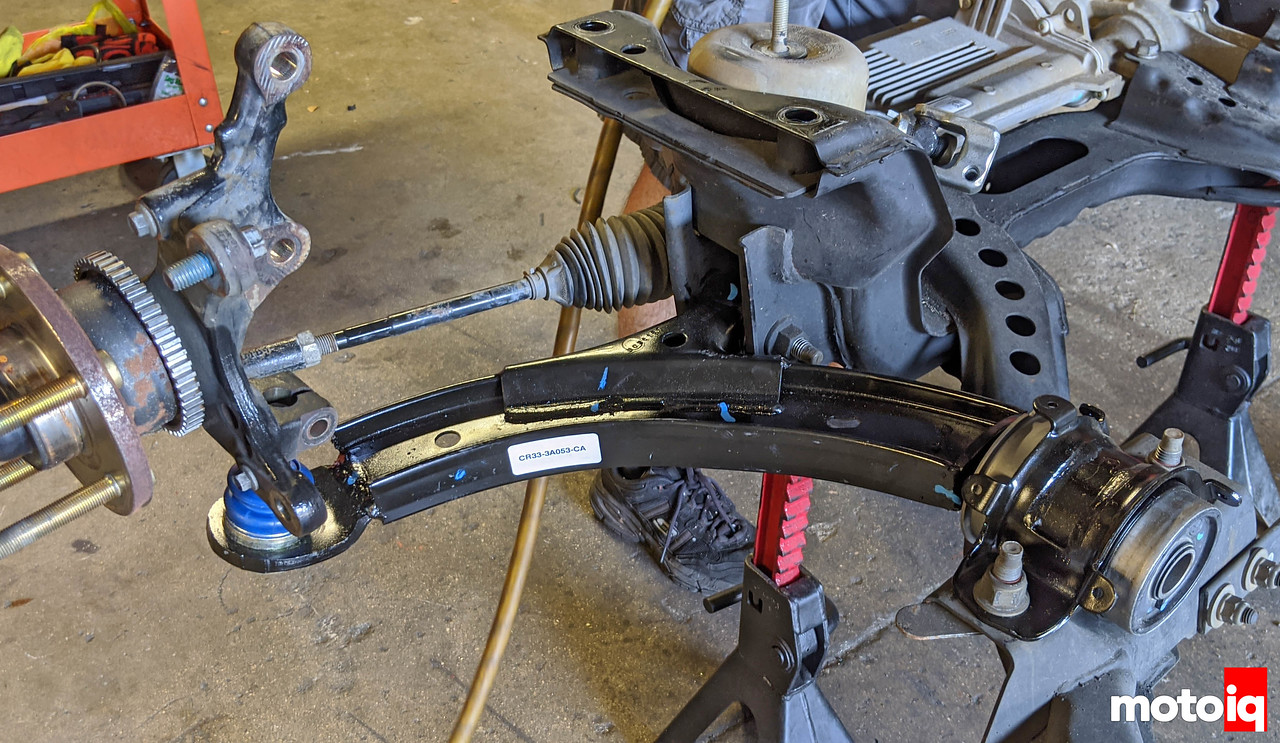

Project Budget 400WHP S197 Mustang Track Car: Part 4 – Installing the Roush 3rd Link

" Upgrading the 3rd link suspension arm in an S197 Mustangs is far more important than just to reduce wheel hop. Picking the right one will greatly affect the car’s handling and rear grip (and we all know Mustangs need rear grip). To improve the performance of our budget track car, we install the best 3rd Link on the market, from Roush Performance."

[/URL]

In the article:

-The importance of the 3rd Link

-Why most aftermarket 3rd Links actually hurt the car's performance and ride quality

-Installation

Project Budget 400WHP S197 Mustang Track Car: Part 5 – Upgrading to an Eaton Truetrac LSD

" A performance Limited Slip Differential is a MUST for making 2005-2014 (S197) Mustangs handle predictably. We replace the weak factory LSD with Eaton’s TrueTrac helical (gear-driven) LSD which will transform the driving experience and character of the car.

[/URL]

In the article:

-Stock LSD vs Torsen-style

-The tech behind Torque Bias Ratios

-Installation

Project Budget 400WHP S197 Mustang Track Car: Part 6 – Going Through the Suspension with Steeda

" This is where we defy the misconceptions and show how to make an S197 Mustang into a corner-carving track car. We are going to cover the pros and cons of Panhard Bars vs Watts Links, and go through the entire suspension with Steeda, picking the least expensive way to make our car fun to drive and competent on track."

[/URL]

In the article:

-Panhard Bar vs Watts Link Pros & Cons

-Analysis: Panhard Bar Geometry vs Watts Link

-Overview & Front S197 Geometry vs Extended Ball Joint LCA

-Front LCA Removal

-Front LCA Install

-Rear Axle Weight Removal

-Rear Lower Control Arm & Panhard Bar Install

Project Budget 400WHP S197 Mustang Track Car: Part 7 – Springs, Shocks, and Bars

" Staying true to the ‘budget’ track car theme, we skipped expensive coilovers and upgraded our S197 Mustang with track-capable springs, shocks, and swaybars from Steeda."

[/URL]

In the article:

-Front and Rear spring, shock and swaybar install

-Lightweight Radiator Support Brace Install

-The importance of a bumpsteer kit when installing extended front balljoints

-Street Review

-The creation of a new Steeda Suspension Package (Based off my feedback and the development of this project car).

-Billy

I read the article bout the Roush 3rd Link usage which caught my attention.

Did y'all use this 3rd link w\ the OEM Ford 2-piece driveshaft under racing conditions or went w\ a 1-piece driveshaft design?

Appreciate any info given.

BillyJRacing

Junior Member

- Joined

- May 9, 2021

- Posts

- 15

- Reaction score

- 3

We had a 1-pc aluminum driveshaft in the 302R.Hi BillyJRacing,

I read the article bout the Roush 3rd Link usage which caught my attention.

Did y'all use this 3rd link w\ the OEM Ford 2-piece driveshaft under racing conditions or went w\ a 1-piece driveshaft design?

Appreciate any info given.

WJBertrand

forum member

- Joined

- Dec 11, 2013

- Posts

- 739

- Reaction score

- 185

I noticed the Roush 3rd link only fits earlier S197 Mustangs. The don't seem to offer one for the '13 model I have.

GlassTop09

Senior Member

Thanks for the response!We had a 1-pc aluminum driveshaft in the 302R.

The reason why I asked was to see if, assuming that the Boss302R used the std OEM Ford S197 rear LCA hole center lengths, the rear axle pinion angle & instant center was being accounted for w\ this Roush 3rd link design to allow the use of a 1-piece driveshaft design since you have the 1st hand knowledge of this part. If I'm interpreting correctly this piece does take all this into account.....or am I missing something?

The pinion angle\instant center info is the only thing that had me hesitant on getting this part for my Stang as I like everything else about it's design features & the info you've given concerning it's use as I currently have a FRPP 1-piece aluminum driveshaft installed using an adj UCA w\ poly bushing & would entertain the advent of removal of this adj UCA since this Roush 3rd link piece would allow full axle articulation, still control wheel hop & maintain\improve grip, is essentially bulletproof but maintains good NVH manners & don't have to mess w\ poly bushing maintenance or any adjustments thus maintenance free (this last part is highly important w\ me).

Appreciate it.

BillyJRacing

Junior Member

- Joined

- May 9, 2021

- Posts

- 15

- Reaction score

- 3

The 2005-2010 Roush 3rd link fits 2011-14 cars. That's what's in "Project Budget 400whp S197 Track Car" (which is a 2014). It's just a little shorter in length than the OEM 2011-14.I noticed the Roush 3rd link only fits earlier S197 Mustangs. The don't seem to offer one for the '13 model I have.

The 2005-10 Roush 3rd link works great on all 2005-2014 cars with OEM and 1-pc AL (or CF) drive shafts. I've won a lot of pro races with this 3rd link on 2014 BOSS 302Rs.Thanks for the response!

The reason why I asked was to see if, assuming that the Boss302R used the std OEM Ford S197 rear LCA hole center lengths, the rear axle pinion angle & instant center was being accounted for w\ this Roush 3rd link design to allow the use of a 1-piece driveshaft design since you have the 1st hand knowledge of this part. If I'm interpreting correctly this piece does take all this into account.....or am I missing something?

The pinion angle\instant center info is the only thing that had me hesitant on getting this part for my Stang as I like everything else about it's design features & the info you've given concerning it's use as I currently have a FRPP 1-piece aluminum driveshaft installed using an adj UCA w\ poly bushing & would entertain the advent of removal of this adj UCA since this Roush 3rd link piece would allow full axle articulation, still control wheel hop & maintain\improve grip, is essentially bulletproof but maintains good NVH manners & don't have to mess w\ poly bushing maintenance or any adjustments thus maintenance free (this last part is highly important w\ me).

Appreciate it.

Pinion angle is the angle of the pinion relative to the driveshaft, which has nothing to do with the instant center of the car, which is determined by the geometry of the 3rd link & lower control arms. They are NOT the same thing or interchangeable since it's possible to change one without affecting the other. There are a lot of misconceptions when it comes to this.

For a car that's driven on the street, it's a no-brainer. I'd just run the Roush 3rd link. Even for racing, in most cases I would still run the Roush link (as explained in the article on the 3rd link).

Norm Peterson

corner barstool sitter

You can use the shorter early UCA, but you also have to use the early UCA chassis-side bracket.I noticed the Roush 3rd link only fits earlier S197 Mustangs. The don't seem to offer one for the '13 model I have.

Might want to use a heavy washer under the fastener that threads into the bracket from the top, as I think the later bracket uses a larger bolt in that position (bigger hole).

Norm

Rich

Member

- Joined

- Dec 26, 2020

- Posts

- 231

- Reaction score

- 175

Is all the bad press the MT-82 gets warranted? I'm wondering if the issues are people beating the shit out of em and complaining (nothing holds up if it gets beat constantly) or if it fails under normal, spirited street driving. Once my auto dies, I would like to swap a manual in it or buy an 11-14 with the MT. Just thinking out loud at this point in time.

07gts197

forum member

I’m not a trans guru but I do know it uses plastic internals. Not the best material for the driveline.

I will say I love the ratios in the mt82. Paired with 3.73s it makes for a great street car. But that’s just my opinion.

Sent from my iPhone using Tapatalk

I will say I love the ratios in the mt82. Paired with 3.73s it makes for a great street car. But that’s just my opinion.

Sent from my iPhone using Tapatalk

Norm Peterson

corner barstool sitter

Which gearset?I will say I love the ratios in the mt82. Paired with 3.73s it makes for a great street car. But that’s just my opinion.

Original MT82 or the later MT82D4?

Norm

07gts197

forum member

Which gearset?

Original MT82 or the later MT82D4?

Norm

Original. 3rd and 4th are a little too close but otherwise I like it much better than the gearing in my previous 5 speeds (t45 and tr3650). There’s no need to rev each gear out just to get up to speed and even with 3.73s I don’t have to shift every couple of seconds. I don’t track the car, just some spirited street driving and based on past experience I think the headset is much better than any previous 5 speed I’ve owned.

Sent from my iPhone using Tapatalk

Might want to use a heavy washer under the fastener that threads into the bracket from the top, as I think the later bracket uses a larger bolt in that position (bigger hole).

Regarding the larger bolt hole if using the older bracket on a newer car (2014). Does this mean that there would be the possibility of unwanted movement at that mounting point due to slop in the bolt hole?

I’ve been looking everywhere for the newer 3rd link and can’t find it anywhere.

Norm Peterson

corner barstool sitter

I highly doubt it. There's still the other two bolts, and FWIW bolted joints like this one resist shear forces (think longitudinal UCA forces here) by friction between the bracket and the sheetmetal. As opposed to direct shear in the bolts, which is what almost everybody assumes is the case. That's part of why there are torque specs for them. If a bolt ever does see direct shear, consider that as being a strictly backup measure (like suspenders plus a belt for your jeans).Regarding the larger bolt hole if using the older bracket on a newer car (2014). Does this mean that there would be the possibility of unwanted movement at that mounting point due to slop in the bolt hole?

My concern was all about the actual area of contact between the bolt head and the sheet metal, and any tendency for the bolt to try to pull through the sheet metal under acceleration loading (rearward UCA force pulls down on this bolt).

Norm

GlassTop09

Senior Member

Concerning the shear force issue w\ the bolts, I believe that that front alignment lug on the 3rd link mount bracket that the front bolt threads into solves that problem. The bolts essentially just attach the mount to the unibody for all practical purposes thus shouldn't experience any shear forces unless that lug itself shears out of the mount bracket so any shear force applied to the front bolt IMHO should be fairly minimal if at all...the 129 ft\lbs TQ spec on this bolt (quoting spec for 05-10 as this 1 I know off the top of my head) is to ensure that the lug doesn't wallow around inside it's socket in the unibody causing the metal it's welded to in the mount bracket to flex thus fail so in my mind the front bolt thru the lug will experience far more tensile force (which is in the front bolt's favor concerning strength....not TTY) than any shear force (the lug thus bracket itself is bearing the brunt of this load) but the 2 rear mount bracket bolts could experience shear force if the front lug\mount bracket metal fails......which is possible but it will take a hella lot of instantaneous shock loading to reach that point (drag racing comes to mind here)....now here's where using either a heim joint or poly bushings in the UCA\LCA's can make this potential easier to reach (along w\ very sticky tires & excessive pinion rise) w\ the stamped steel 3rd link mount bracket due to too little\no bushing deflection\dampening (this is what Billy is saying causes less grip by excessive tire shock breaking traction earlier than otherwise when accelerating) but normal street\road racing operations shouldn't be an issue. Probably why most aftermarket pieces use 1\4" plate steel w\ gussets to build the UCA mount bracket......I highly doubt it. There's still the other two bolts, and FWIW bolted joints like this one resist shear forces (think longitudinal UCA forces here) by friction between the bracket and the sheetmetal. As opposed to direct shear in the bolts, which is what almost everybody assumes is the case. That's part of why there are torque specs for them. If a bolt ever does see direct shear, consider that as being a strictly backup measure (like suspenders plus a belt for your jeans).

My concern was all about the actual area of contact between the bolt head and the sheet metal, and any tendency for the bolt to try to pull through the sheet metal under acceleration loading (rearward UCA force pulls down on this bolt).

Norm

I just can't see any engineer designing this piece to take the kinds of longitudinal forces this UCA could see on bolt shank shear force capability alone......

Norm Peterson

corner barstool sitter

Me either.I just can't see any engineer designing this piece to take the kinds of longitudinal forces this UCA could see on bolt shank shear force capability alone......

Norm

Similar threads

- Replies

- 5

- Views

- 216

- Replies

- 13

- Views

- 756

Support us!

Support Us - Become A Supporting Member Today!

Click Here For Details