AutoXRacer

forum member

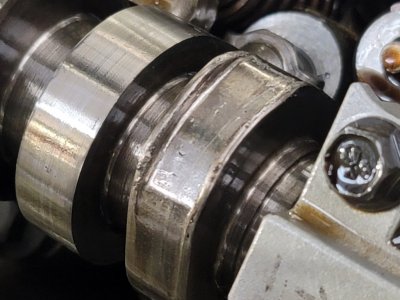

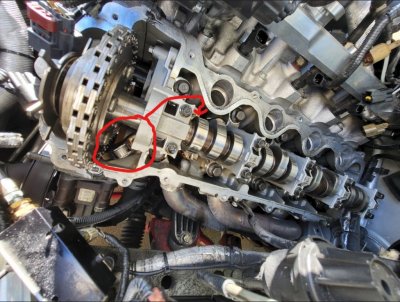

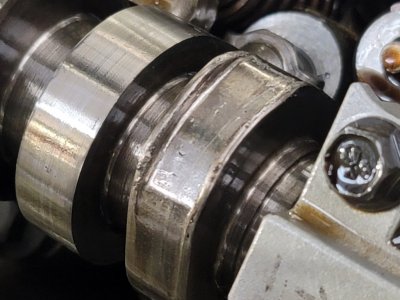

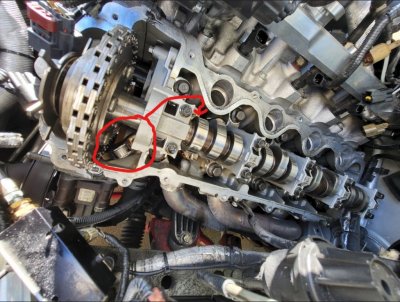

I've experienced catastrophic valve train failure due to failing cam follwers (rollers / arms); both driver and passenger side.

Has anyone else experienced this? Did you ever figure out the cause? My followers are failing in just a few thousand miles; less than 10K I believe. The rollers end up locking up...figuring the needle bearings are failing. I have found 6 followers in addition to the completely failed with rough rollers.

My valve train setup is Comp Cams 127450, PAC 3V Springs (Pac springs are 105 seat pressure @ 1.670 and the open pressure is 270lbs @ 1.120 says max lift of .550"), in Ford Racing CNC & Ported heads; my phasers are locked, VCT removed, and timing retarded 4 degrees.

View attachment 83707

View attachment 83708

Has anyone else experienced this? Did you ever figure out the cause? My followers are failing in just a few thousand miles; less than 10K I believe. The rollers end up locking up...figuring the needle bearings are failing. I have found 6 followers in addition to the completely failed with rough rollers.

My valve train setup is Comp Cams 127450, PAC 3V Springs (Pac springs are 105 seat pressure @ 1.670 and the open pressure is 270lbs @ 1.120 says max lift of .550"), in Ford Racing CNC & Ported heads; my phasers are locked, VCT removed, and timing retarded 4 degrees.

View attachment 83707

View attachment 83708

Last edited: