Brick

forum member

Not that it matters, but what does the bolt go to? I don't remember any aluminum bolts on the motor. Hang in there, you'll get it. Sometimes I will walk away from this type of problem for an hour and come back and get it right away.

It was actually a stainless steel bolt, in the panic of it dropping and realizing it wasn't magnetic I just assumed it was aluminum... but now that I'm thinking straight I've never even heard of an aluminum bolt. The one I dropped secures the fuel rail to the FRPP manifold.

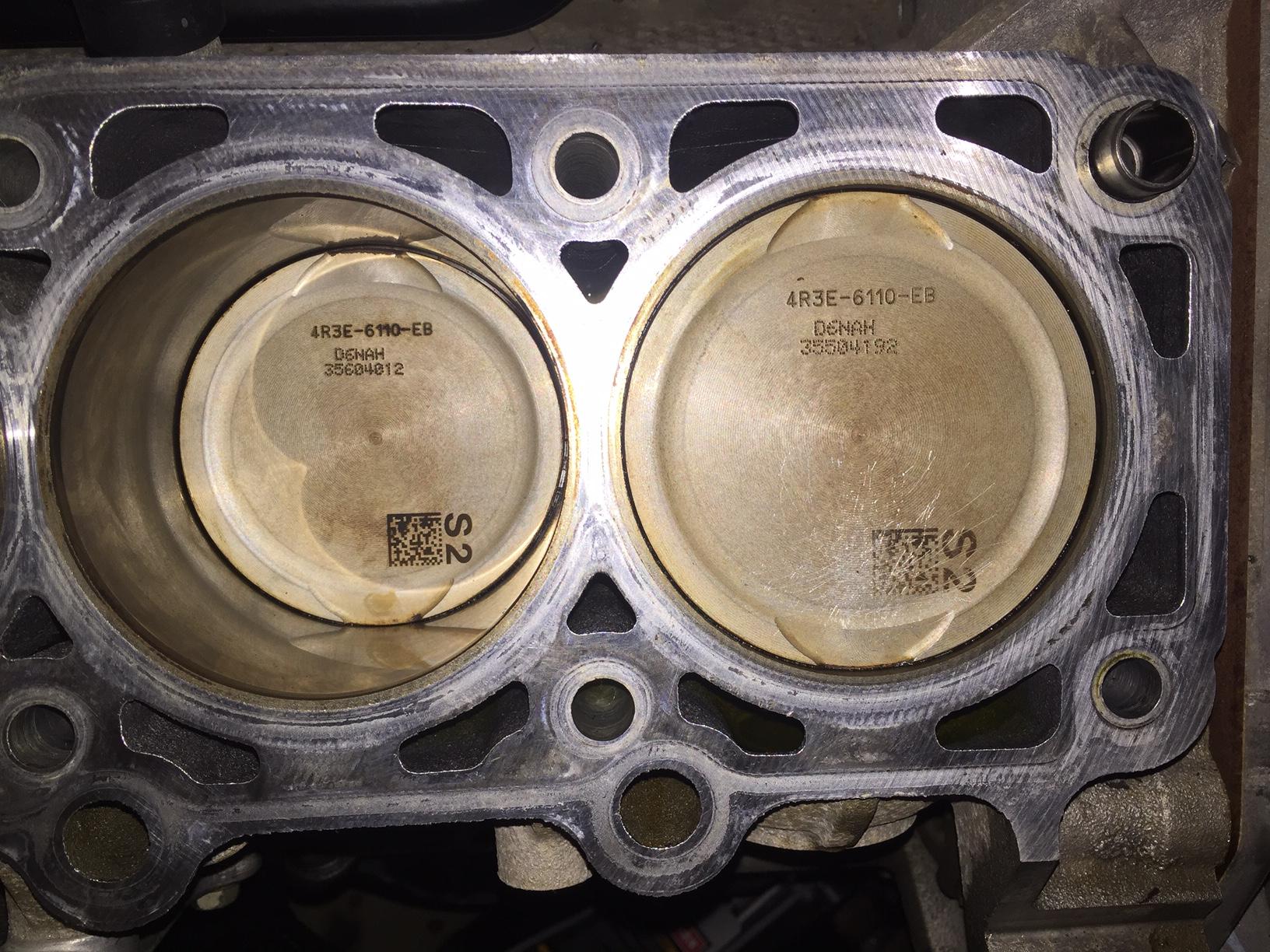

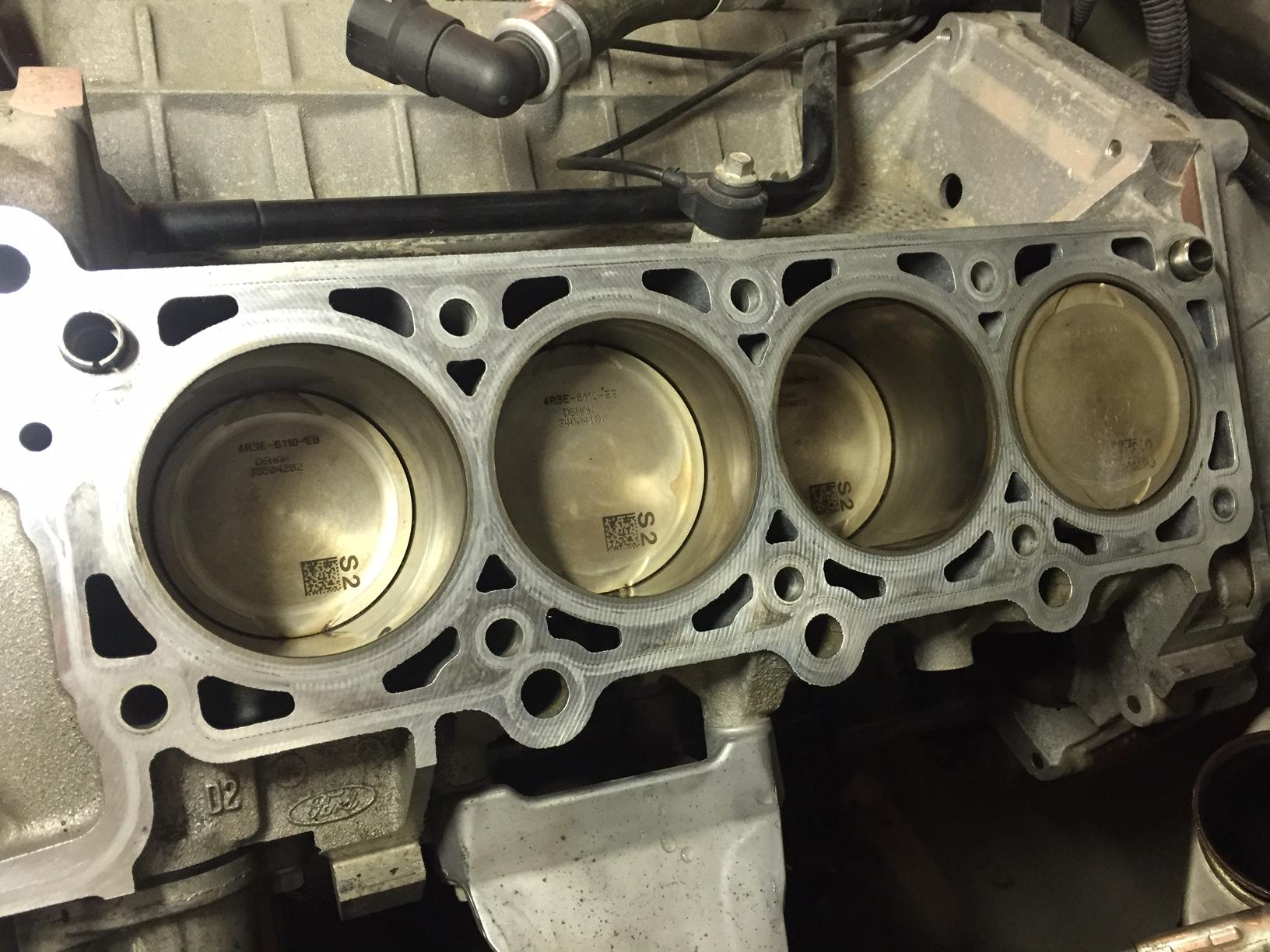

I got it out. After spending a few hours trying to fish it out, I ended up just pulling the head. After getting the head off, I don't think theres any way I could've pulled it back out the plug hole - unless I was able to stand it up on end and grab it by the threads with the claw. The round head of the bolt was perfectly matched to the plug hole with no wiggle room.

For anyone who might reference this thread in the future, I think the best chance of getting anything out of there would be to do as 05moneypit suggested. Pull the intake manifold and open the intake valve as far as you can with a valve spring compressor. Then use a claw tool(s) through the valve and/or spark plug hole to remove it. Trimming down the teeth on the claw will give a little more clearance to get it down there. With enough patience I probably could have gotten it out this way.

Never again will I ever leave any hole into the engine open where something can fall through. Thank you guys for all your help!