Where to start? lol

They have pros and cons as anything from a driveability, tuneability and reliability standpoint this is what I have found. Returnless setups are great and do well for the average setup up to around 700-800hp on gas and 600-700 on corn. You can always mod the system to go past that, bap, rails line filter upgrades, pprv delete etc. These mods help a lot and are all things done on a return setup that are being carried over to returnless. E85 will always favor a return setup from a flow standpoint alone mechincal regulation will always be better responding to the increased flow demand. Not that you cant make a returnless setup work. I love returnless setups and moding them making them work, but going return for my power goals(700hp+) on e85 was a no brainer and I'm glad I did.

Another thing to note, you always get such wide results from guy to guy running the same returnless mod'd setup. I deal with this all the time. You don't get that with return setups they are more direct and up front with the hp they make and its not a big difference from setup to setup.

Dead head setup: So yes this is one of the many ways to do it and while it will work and is the simplest, less hoses and connections etc. It is the least desirable for a high hp application imho. One reason is path of least resistance when it comes to flow because the fuel is returned to the tank right a the regulator pre-rails (before the load/injectors take the fuel). You will not get as much flow and hp potential though the rails as you would on a setup that mounts the regulator post rail and all the flow must go through the rails (which is most common/preferred method.) Regulator valve design and internal geometry also play a role in this, not all regulators are designed to be "dead head" supportive. Some regulators only support pass through regulation from certain port configurations etc. That aeromotive regulator appears to have the proper setup for dead head from what I can see. I know Fore's cheapest stage 1 kit is a dead head kit and he only rates it to 800hp, where as the series/parallel rail with post rail regulator setups are rated to 1200hp. Not that the dead head setup cant work and wont work well when setup up correctly. There is a more positive determination of hp potential when all fuel flow must pass through the rails. The dead head setup gives the flow a choice on going out to each rail or going back down to the tank so you cant say for sure there isn't a flow/pressure differential from each leg, again regulator design and geometry with help this.

Pressure

The base pressure in a return setup is/can be setup no different than delta pressure in a returnless setup like mentioned. The regulator gets a boost/vac signal just like the frps does on the oem setup. And base pressure ( pressure set at the regulator with the car off and pumps on) is maintained just as delta pressure is by the pcm.

The return setup with mechanical regulator will always be better controlled and more accurate than a returnless setup. As the regulator is mounted up at the rails where the load is. As mentioned this really shines at high flow high hp levels. The mechanical regulator responds instantaneously to maintain base pressure as flow is always there and the valve is all that moves. In returnless you are also still subject to the rate of flow change cause by the pump when its modulated so its not precise adjustability like the valve in the regulator. While the pcm is pulsing the pumps will always be playing catch up to whats going on. (frps at the rail and fpdm pulsing the pump down in the tank) The biggest lag here is pressure differential due to the frps being so far away from the pump from what I have seen. Also large changes in boost/vac, while the frps and pcm in turn see it right away the pump itself responding is not as quick.

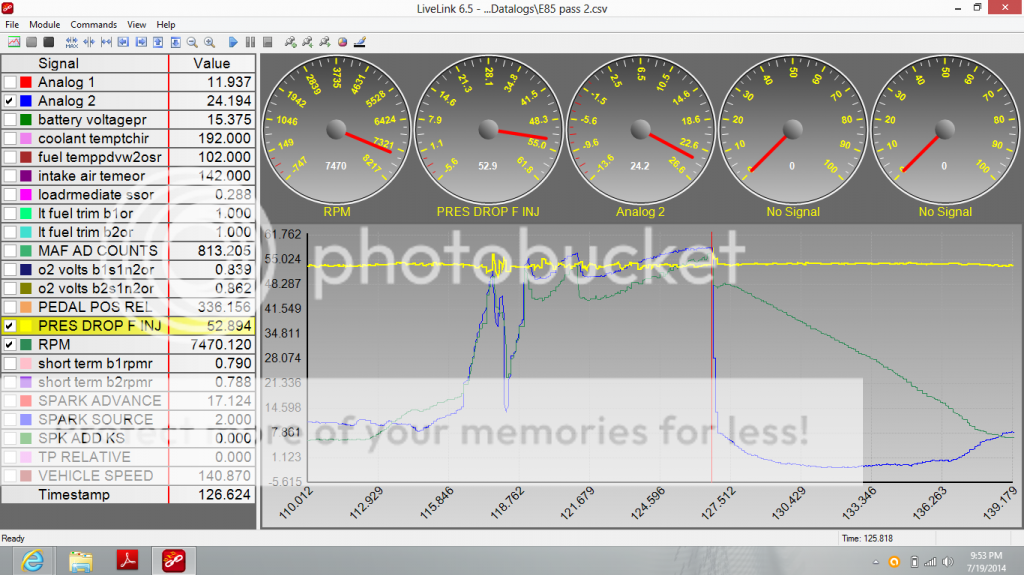

An example of how they compare in this regard is when I was testing my bap on my returnless setup, I had the car on and idling. I would wing the knob from full lean to full rich and the fuel pressure would jump from the 30's at idle to 50-55psi and take a few seconds to come back down to delta where it was. On my return setup I was doing a similar test to test the trigger for my second 465 pump. The regulator is set at 43psi and the car is on idling at 32ish psi (my regulator is boost/vac referenced). I tested the trigger and heard the pump comeing on, so remembering my results from testing the bap, I turned to watch my fuel pressure gauge. This time my fuel pressure was still solid there was the faintest twitch noticeable when the pump kicked on and I just added 430lph+ of flow to the system compared to 100-150lph a bap will add. Noticeable difference for sure for me.

Another example to mention is I ran run out of gas a few times before on my returnless setup, in each case fuel pressure began bouncing wildly before hand and then dropping slowly to zero and then car shut off. When I was driving out the rest of the 93 out of my tank on the way to the track on the return setup I was expecting the same results to know when to pull over and add the e85 I had in the trunk. However pressure stayed rock solid up until the car shut off and pressure dropped right to zero.

This gives you some insight on how a regulator responds compared to a frps/fpdm.

I will try to find some vids of before and after, on my many returnless setups, they always bounced pressure even at steady state operation.

With the regulator pressure is rock solid everywhere, at key on, idling after vac is applied and when it ramps up with boost to maintain base pressure.

Bruce I envy you, you have the ability to tune your own car and have lots of experience with your setup which is a huge plus for you making it easy to dial in for your changing setups. Your average tuner tunes thousands of different setups and that goes hand in hand with tuning issues in returnless fuel systems. They don't get all the attention and time that you can put into your own setup and that's why so many guys have issues. As some one that makes fuel systems, I have found the many ins and outs of this and learned a lot about it. And from this often ask guys who they use for tuning before I recommend a fuel system.

They have pros and cons as anything from a driveability, tuneability and reliability standpoint this is what I have found. Returnless setups are great and do well for the average setup up to around 700-800hp on gas and 600-700 on corn. You can always mod the system to go past that, bap, rails line filter upgrades, pprv delete etc. These mods help a lot and are all things done on a return setup that are being carried over to returnless. E85 will always favor a return setup from a flow standpoint alone mechincal regulation will always be better responding to the increased flow demand. Not that you cant make a returnless setup work. I love returnless setups and moding them making them work, but going return for my power goals(700hp+) on e85 was a no brainer and I'm glad I did.

Another thing to note, you always get such wide results from guy to guy running the same returnless mod'd setup. I deal with this all the time. You don't get that with return setups they are more direct and up front with the hp they make and its not a big difference from setup to setup.

Dead head setup: So yes this is one of the many ways to do it and while it will work and is the simplest, less hoses and connections etc. It is the least desirable for a high hp application imho. One reason is path of least resistance when it comes to flow because the fuel is returned to the tank right a the regulator pre-rails (before the load/injectors take the fuel). You will not get as much flow and hp potential though the rails as you would on a setup that mounts the regulator post rail and all the flow must go through the rails (which is most common/preferred method.) Regulator valve design and internal geometry also play a role in this, not all regulators are designed to be "dead head" supportive. Some regulators only support pass through regulation from certain port configurations etc. That aeromotive regulator appears to have the proper setup for dead head from what I can see. I know Fore's cheapest stage 1 kit is a dead head kit and he only rates it to 800hp, where as the series/parallel rail with post rail regulator setups are rated to 1200hp. Not that the dead head setup cant work and wont work well when setup up correctly. There is a more positive determination of hp potential when all fuel flow must pass through the rails. The dead head setup gives the flow a choice on going out to each rail or going back down to the tank so you cant say for sure there isn't a flow/pressure differential from each leg, again regulator design and geometry with help this.

Pressure

The base pressure in a return setup is/can be setup no different than delta pressure in a returnless setup like mentioned. The regulator gets a boost/vac signal just like the frps does on the oem setup. And base pressure ( pressure set at the regulator with the car off and pumps on) is maintained just as delta pressure is by the pcm.

The return setup with mechanical regulator will always be better controlled and more accurate than a returnless setup. As the regulator is mounted up at the rails where the load is. As mentioned this really shines at high flow high hp levels. The mechanical regulator responds instantaneously to maintain base pressure as flow is always there and the valve is all that moves. In returnless you are also still subject to the rate of flow change cause by the pump when its modulated so its not precise adjustability like the valve in the regulator. While the pcm is pulsing the pumps will always be playing catch up to whats going on. (frps at the rail and fpdm pulsing the pump down in the tank) The biggest lag here is pressure differential due to the frps being so far away from the pump from what I have seen. Also large changes in boost/vac, while the frps and pcm in turn see it right away the pump itself responding is not as quick.

An example of how they compare in this regard is when I was testing my bap on my returnless setup, I had the car on and idling. I would wing the knob from full lean to full rich and the fuel pressure would jump from the 30's at idle to 50-55psi and take a few seconds to come back down to delta where it was. On my return setup I was doing a similar test to test the trigger for my second 465 pump. The regulator is set at 43psi and the car is on idling at 32ish psi (my regulator is boost/vac referenced). I tested the trigger and heard the pump comeing on, so remembering my results from testing the bap, I turned to watch my fuel pressure gauge. This time my fuel pressure was still solid there was the faintest twitch noticeable when the pump kicked on and I just added 430lph+ of flow to the system compared to 100-150lph a bap will add. Noticeable difference for sure for me.

Another example to mention is I ran run out of gas a few times before on my returnless setup, in each case fuel pressure began bouncing wildly before hand and then dropping slowly to zero and then car shut off. When I was driving out the rest of the 93 out of my tank on the way to the track on the return setup I was expecting the same results to know when to pull over and add the e85 I had in the trunk. However pressure stayed rock solid up until the car shut off and pressure dropped right to zero.

This gives you some insight on how a regulator responds compared to a frps/fpdm.

I will try to find some vids of before and after, on my many returnless setups, they always bounced pressure even at steady state operation.

With the regulator pressure is rock solid everywhere, at key on, idling after vac is applied and when it ramps up with boost to maintain base pressure.

Bruce I envy you, you have the ability to tune your own car and have lots of experience with your setup which is a huge plus for you making it easy to dial in for your changing setups. Your average tuner tunes thousands of different setups and that goes hand in hand with tuning issues in returnless fuel systems. They don't get all the attention and time that you can put into your own setup and that's why so many guys have issues. As some one that makes fuel systems, I have found the many ins and outs of this and learned a lot about it. And from this often ask guys who they use for tuning before I recommend a fuel system.

Last edited: