05stroker

Never enough power guy!

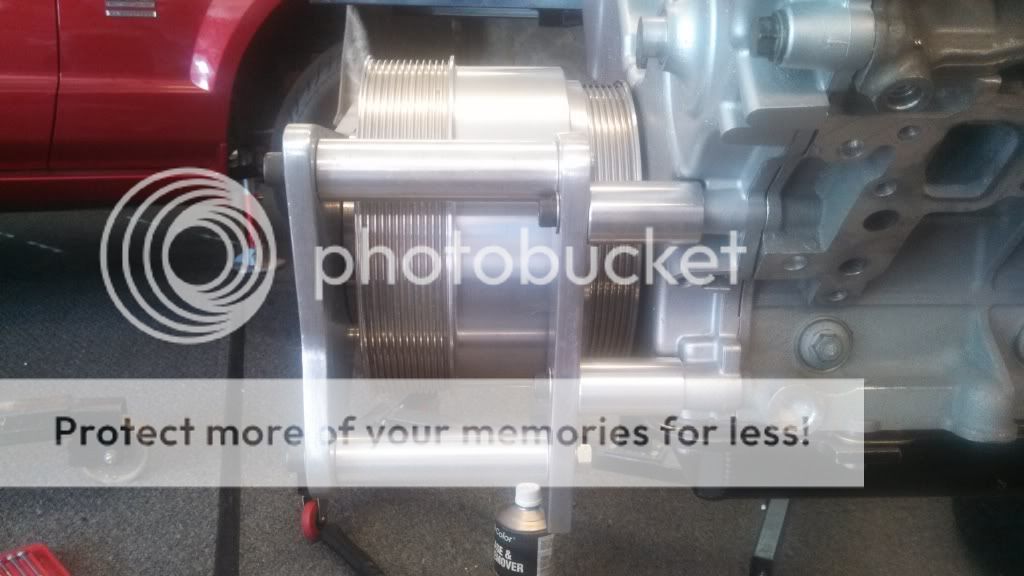

Here's a picture of an air to water intercooler I saw for the procharger kits for our cars.

Just thought I'd throw it out here.

Sent from my HTC One_M8 using Tapatalk

Where does that fit? Looks like in front of the TB, just not sure what has to happen there.

I'm not doing ATW with my Procharger. The ATA I have now works fine for E85.

You won't see an ATW on my car till the 80mm turbo goes on it.