GlassTop09

Senior Member

Update:

Still waiting on tuner to get caught up to schedule a dyno session (in process of hiring another shop tech to free up tuner--tuner is the shop's general manager as well as performance tuner--was told to expect a call within a couple of weeks)....but in the process I've captured some more data to show the reasoning behind my removing the FRPP IM when emissions is a concern (cat operation in particular) & noting some other cause\effect from other issues as well:

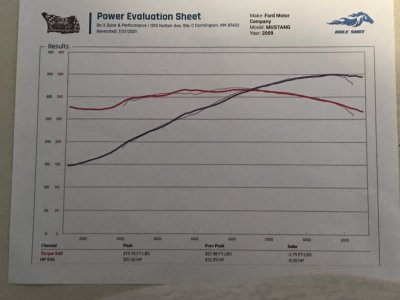

Below is a copy of a FORScan OBDII Mode 6 Component Self Check result dated 11-18-20 to show where my car was at using the engine parts used at that time (FRPP Bullitt 85mm CAI using OEM MC MAF sensor, FRPP 62mm TB, FRPP IM, Lunati VooDoo #21270700 cams, Kooks 1 5/8" LTH's w\ Catted X-Pipe using BDG 90* CEL Eliminators, 4-Ford OEM F85F-9G4444-BD O2 sensors, MC OEM HJFS-24FP Spark Plugs all thru last PCM tune done on 4-2-20). Please note the Catalyst 1 & Catalyst 2 OBDII Threshold readings the PCM tested the cats efficiency to be. Had no idea as to the condition of the O2 sensors\spark plugs or of the EVAP port routing in the FRPP IM at this time.

(Note: Now the BDG 90* CEL Eliminators I'm using DO NOT have the internal mini cat substrate inside to further skew the rear O2 sensor readout by altering the free O2 % in the exhaust sample that enters them thus are only an open chamber w\ a 1\4" entry\exit port open to exhaust flow so they work by reducing the rear O2 sensor exhaust sample % exchange rate around rear O2 sensor's element vs the actual flowing exhaust sample % in exhaust pipe post-cat to slow the rear O2 sensor's rich to lean; lean to rich transition (V\ms) switch rate vs the pre cat O2 sensor's lean\rich amplitude switch rate around stoich (how the PCM determines the amount of free exhaust O2 that got thru the cat vs what enters it to calc the cat's operating efficiency)...so the results shown thru these BDG Eliminators will also correspond in proportion to what is occurring within the cats themselves as the exhaust sample exchange rate inside the eliminators is determined by the 1\4" entry\exit port so the Cat Efficiency curve derived inside these Eliminators is very relative to what is actually occurring in the exhaust pipe post-cat. Any O2 reduction inside the Eliminators is due to a proportional O2 reduction in exhaust piping post-cat. FYI.......)

Now please note what I typed in the post script (PS 4-11-21 of B1 Cat Effic @ .215; B2 Cat Effic @ .219) of my post #137 when I checked the Mode 6 data using my Foxwell NT301 scan tool after initial KAM reset. This is representative of cat efficiency improvement from the IM swap concerning the EVAP porting difference between the FRPP IM vs the OEM IM w\ CMDP's alone when compared to the 1st FORScan recorded Mode 6 data @ 11-18-20.

Now I also used my Foxwell NT301 scan tool to do the same thing after I ran a test @ 4-20-21 observing thru live data the Ford pre-cat O2 sensor voltages during OL to CL transition, found them not operating well at all causing excessively rich fueling until they responded (as noted in 1st part of post #140) so pulled them & reinstalled my NTK 22060\22500 O2 sensors & tested these in same manner to see\verify the operational improvement between the 2 sets of O2 sensors then performed KAM reset & ran thru 2 full drive cycles to fully complete all monitors beforehand.....the B1 Cat Effic @ .126; B2 Cat Effic @ .134.....notice the amount of improvement now w\ only the IM + O2 sensor changeout so the pre-cat, post-cat O2 sensor operational accuracy is just as important if not more so for good Cat Efficiency results.

Since that time I've finally gotten around to getting my FORScan extended license. While using FORScan to go thru & save all module AS-BUILT data as currently programmed for back up purposes & cleaning up other module's DTC's that were set before I bought the car but were never cleared when the issues were fixed (got all cleaned up except the GEM\SJB B2053...LF Repeater Lamp Circuit Malf....but all is physically working so don't know what's keeping SJB triggering this DTC yet & B2276 Less Than 2 Transmitters Programmed....figured this 1 out-have only programmed 1 key w\fob using the SJB in-car key\fob transmitter programming process since I had locksmith reset the SJB security when they cut\programmed my initial spare keys & original key fob after car purchase so I can dismiss this 1) I used FORScan to record the Mode 6 data after finding\replacing the bad spark plugs I posted about in my last post #140 then reset KAM using my Foxwell NT301 scan tool & ran car thru 2 full drive cycles to fully complete all monitors. Pulled the Mode 6 data this morning (car has been sitting idle for some time while doing yard work & pulling weeds around fence in service alley then recovering from the allergy & muscle spasms....) & have posted it below.....

The Cat Efficiency improvement results shown in this data are from the IM changeout, then O2 sensor changeout, then spark plug changeout.....all else is the same including the tune.

Am tempted to drop the midpipe to remove the BDG CEL Eliminators 1 more time, reinstall the rear O2 sensors back in the exhaust piping post-cats then rerun the monitors to test the Kooks Race cats again under this OEM IM w\ CMDP's, NTK O2 sensors & good Champion 9406 Iridium plugs to see if they'll now retain\hold a passing IM Readiness Cat Efficiency test result but I think I'm just gonna run all as is for now & wait to see what changes after the dyno\retune session before doing anything else exhaust wise.

Interesting how other physical items, parts design differences can have a far larger impact on actual Cat Efficiency than actual tuning changes or even a cat's internal design. The good thing for me in this scenario is the Kooks Race Cat's substrate being made of metallic foil instead of ceramic.....metal substrates don't degrade nowhere near as easily as ceramic, can withstand far higher exhaust temps nor are as easily poisoned since no oils can penetrate into the metallic foil so are more easily recoverable from contamination as long as none of the cell channels get completely plugged off w\ carbon to reduce usable substrate surface treating area.

FYI......................

PS--Looking back thru the 11-18-20 Mode 6 data, the misfire counts pattern should have clued me into checking the plugs, especially all plugs on B1 but since no DTC's were flagged, counts were small in number & no detected actual hard plug misfires at that time I easily dismissed the data....but when compared to the 6-9-21 data saved this morning of a fully, properly operating engine this becomes very obvious........

Shows the importance of having good recorded baseline data of a properly operating engine system on hand to use to spot upcoming issues before they get out of hand.......while waiting on a DTC to alert you.............

Almost forgot......my tuner also sent me a text to inform me after I sent him the pictures of the burnt up MC plugs that he recommended to use NGK Iridium IX series plugs going forward as he didn't think very highly of Brisk plugs from his experiences using them in the past vs NGK (which do cross match heat range-wise w\ the MC HJFS-24P plugs as do the Champion 9406 Iridium plugs but were cheaper than the NGK's so I bought the Champions back in summer 2019) so whenever the Champions finally give out I'll pick up a set of the NGK's to try out on my tuner's recommendation.

Still waiting on tuner to get caught up to schedule a dyno session (in process of hiring another shop tech to free up tuner--tuner is the shop's general manager as well as performance tuner--was told to expect a call within a couple of weeks)....but in the process I've captured some more data to show the reasoning behind my removing the FRPP IM when emissions is a concern (cat operation in particular) & noting some other cause\effect from other issues as well:

Below is a copy of a FORScan OBDII Mode 6 Component Self Check result dated 11-18-20 to show where my car was at using the engine parts used at that time (FRPP Bullitt 85mm CAI using OEM MC MAF sensor, FRPP 62mm TB, FRPP IM, Lunati VooDoo #21270700 cams, Kooks 1 5/8" LTH's w\ Catted X-Pipe using BDG 90* CEL Eliminators, 4-Ford OEM F85F-9G4444-BD O2 sensors, MC OEM HJFS-24FP Spark Plugs all thru last PCM tune done on 4-2-20). Please note the Catalyst 1 & Catalyst 2 OBDII Threshold readings the PCM tested the cats efficiency to be. Had no idea as to the condition of the O2 sensors\spark plugs or of the EVAP port routing in the FRPP IM at this time.

(Note: Now the BDG 90* CEL Eliminators I'm using DO NOT have the internal mini cat substrate inside to further skew the rear O2 sensor readout by altering the free O2 % in the exhaust sample that enters them thus are only an open chamber w\ a 1\4" entry\exit port open to exhaust flow so they work by reducing the rear O2 sensor exhaust sample % exchange rate around rear O2 sensor's element vs the actual flowing exhaust sample % in exhaust pipe post-cat to slow the rear O2 sensor's rich to lean; lean to rich transition (V\ms) switch rate vs the pre cat O2 sensor's lean\rich amplitude switch rate around stoich (how the PCM determines the amount of free exhaust O2 that got thru the cat vs what enters it to calc the cat's operating efficiency)...so the results shown thru these BDG Eliminators will also correspond in proportion to what is occurring within the cats themselves as the exhaust sample exchange rate inside the eliminators is determined by the 1\4" entry\exit port so the Cat Efficiency curve derived inside these Eliminators is very relative to what is actually occurring in the exhaust pipe post-cat. Any O2 reduction inside the Eliminators is due to a proportional O2 reduction in exhaust piping post-cat. FYI.......)

Now please note what I typed in the post script (PS 4-11-21 of B1 Cat Effic @ .215; B2 Cat Effic @ .219) of my post #137 when I checked the Mode 6 data using my Foxwell NT301 scan tool after initial KAM reset. This is representative of cat efficiency improvement from the IM swap concerning the EVAP porting difference between the FRPP IM vs the OEM IM w\ CMDP's alone when compared to the 1st FORScan recorded Mode 6 data @ 11-18-20.

Now I also used my Foxwell NT301 scan tool to do the same thing after I ran a test @ 4-20-21 observing thru live data the Ford pre-cat O2 sensor voltages during OL to CL transition, found them not operating well at all causing excessively rich fueling until they responded (as noted in 1st part of post #140) so pulled them & reinstalled my NTK 22060\22500 O2 sensors & tested these in same manner to see\verify the operational improvement between the 2 sets of O2 sensors then performed KAM reset & ran thru 2 full drive cycles to fully complete all monitors beforehand.....the B1 Cat Effic @ .126; B2 Cat Effic @ .134.....notice the amount of improvement now w\ only the IM + O2 sensor changeout so the pre-cat, post-cat O2 sensor operational accuracy is just as important if not more so for good Cat Efficiency results.

Since that time I've finally gotten around to getting my FORScan extended license. While using FORScan to go thru & save all module AS-BUILT data as currently programmed for back up purposes & cleaning up other module's DTC's that were set before I bought the car but were never cleared when the issues were fixed (got all cleaned up except the GEM\SJB B2053...LF Repeater Lamp Circuit Malf....but all is physically working so don't know what's keeping SJB triggering this DTC yet & B2276 Less Than 2 Transmitters Programmed....figured this 1 out-have only programmed 1 key w\fob using the SJB in-car key\fob transmitter programming process since I had locksmith reset the SJB security when they cut\programmed my initial spare keys & original key fob after car purchase so I can dismiss this 1) I used FORScan to record the Mode 6 data after finding\replacing the bad spark plugs I posted about in my last post #140 then reset KAM using my Foxwell NT301 scan tool & ran car thru 2 full drive cycles to fully complete all monitors. Pulled the Mode 6 data this morning (car has been sitting idle for some time while doing yard work & pulling weeds around fence in service alley then recovering from the allergy & muscle spasms....) & have posted it below.....

The Cat Efficiency improvement results shown in this data are from the IM changeout, then O2 sensor changeout, then spark plug changeout.....all else is the same including the tune.

Am tempted to drop the midpipe to remove the BDG CEL Eliminators 1 more time, reinstall the rear O2 sensors back in the exhaust piping post-cats then rerun the monitors to test the Kooks Race cats again under this OEM IM w\ CMDP's, NTK O2 sensors & good Champion 9406 Iridium plugs to see if they'll now retain\hold a passing IM Readiness Cat Efficiency test result but I think I'm just gonna run all as is for now & wait to see what changes after the dyno\retune session before doing anything else exhaust wise.

Interesting how other physical items, parts design differences can have a far larger impact on actual Cat Efficiency than actual tuning changes or even a cat's internal design. The good thing for me in this scenario is the Kooks Race Cat's substrate being made of metallic foil instead of ceramic.....metal substrates don't degrade nowhere near as easily as ceramic, can withstand far higher exhaust temps nor are as easily poisoned since no oils can penetrate into the metallic foil so are more easily recoverable from contamination as long as none of the cell channels get completely plugged off w\ carbon to reduce usable substrate surface treating area.

FYI......................

PS--Looking back thru the 11-18-20 Mode 6 data, the misfire counts pattern should have clued me into checking the plugs, especially all plugs on B1 but since no DTC's were flagged, counts were small in number & no detected actual hard plug misfires at that time I easily dismissed the data....but when compared to the 6-9-21 data saved this morning of a fully, properly operating engine this becomes very obvious........

Shows the importance of having good recorded baseline data of a properly operating engine system on hand to use to spot upcoming issues before they get out of hand.......while waiting on a DTC to alert you.............

Almost forgot......my tuner also sent me a text to inform me after I sent him the pictures of the burnt up MC plugs that he recommended to use NGK Iridium IX series plugs going forward as he didn't think very highly of Brisk plugs from his experiences using them in the past vs NGK (which do cross match heat range-wise w\ the MC HJFS-24P plugs as do the Champion 9406 Iridium plugs but were cheaper than the NGK's so I bought the Champions back in summer 2019) so whenever the Champions finally give out I'll pick up a set of the NGK's to try out on my tuner's recommendation.

Attachments

Last edited: