Came across some good information for injectors on the web, so decided to start a thread with it and a place for guys to discuss and post injector stuff.

For starters, all Ford injector flow rates are calculated at 39.15 psi. Where as some cars run at 43.5 psi. So the observed max flow rating can actualy be slightly higher. Multiply by 1.054 to get the actaul flow capability on a 43.5 psi setup. So a 60lb injector would actualy flow 63.24 lbs per hour but remember an injector will only flow to about 90-92% of its rating then become static.

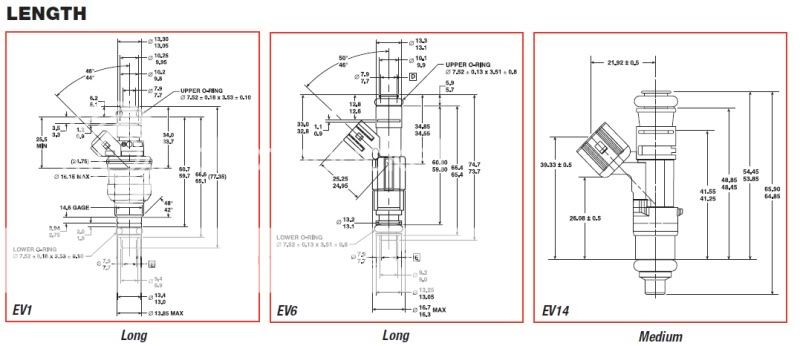

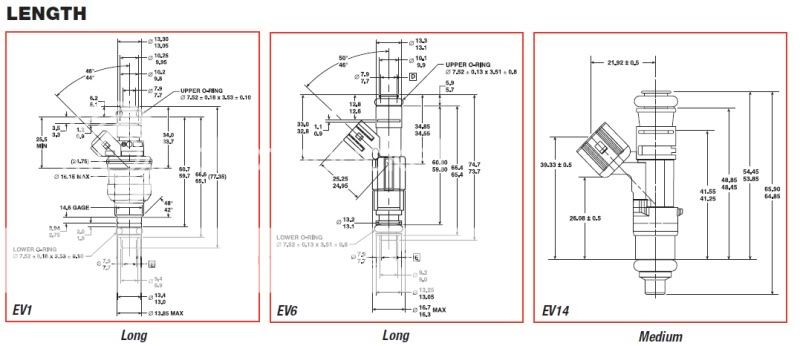

Ford injectors have an ev number, this refers to the body style(dimensions width/height etc) and actualy has nothing to do with the style connector required.

EV1 and EV6 style injectors are the same height essentialy from o-ring to o-ring but the EV1 has a wider body or is a "fat" injector and they use a different style connector, they are often easily interchangeable.

EV14 is a slightly shorter injector and has a similiar width to the EV6. The gt500, v6 and whipple kits for the GT use an EV14 height injector.

Injector connector style

There are two basic styles used for the injector harness connector. A jetronic or uscar connector.

Older mustangs used jetronic while the 05+ use the uscar connector. You can use a jetronic style connector injector still on our cars or vice versa but it will require an adaptor. EV1 injectors have a jetronic connector and EV6 come with an uscar connector.

http://www.fordracingparts.com/download/charts/Fuel_Injectors_and_Adaptors.pdf

You can use the following information to properly determine what size injectors are needed for various applications. For this example, we will use a naturally aspirated 5.0L V8 engine making 300 hp. Keep in mind that this is FLYWHEEL (also known as brake) horsepower, NOT wheel horsepower.

which gives:

This can cause extreme variability in the amount of fuel actually injected, which can sometimes result in a rich condition. Similar issues exist at the low end of the flow region at extremely low duty cycles, but this is highly dependent on the type and flow rate of each model of injector. In this case the injector does not have enough time to fully open before it is commanded to close again, which causes extreme variability that can result in a lean condition. For these reasons, we generally recommended selecting an injector with a flow rate sufficiently high that it will not be required to exceed an 85% duty cycle. So to figure out what size fuel injector will result in an 85% duty cycle, divide the original result by 0.85:

Here is an online calculator that can help you determine the right size injector for your setup.

http://www.witchhunter.com/injectorcalc1.php4

For starters, all Ford injector flow rates are calculated at 39.15 psi. Where as some cars run at 43.5 psi. So the observed max flow rating can actualy be slightly higher. Multiply by 1.054 to get the actaul flow capability on a 43.5 psi setup. So a 60lb injector would actualy flow 63.24 lbs per hour but remember an injector will only flow to about 90-92% of its rating then become static.

Ford injectors have an ev number, this refers to the body style(dimensions width/height etc) and actualy has nothing to do with the style connector required.

EV1 and EV6 style injectors are the same height essentialy from o-ring to o-ring but the EV1 has a wider body or is a "fat" injector and they use a different style connector, they are often easily interchangeable.

EV14 is a slightly shorter injector and has a similiar width to the EV6. The gt500, v6 and whipple kits for the GT use an EV14 height injector.

Injector connector style

There are two basic styles used for the injector harness connector. A jetronic or uscar connector.

Older mustangs used jetronic while the 05+ use the uscar connector. You can use a jetronic style connector injector still on our cars or vice versa but it will require an adaptor. EV1 injectors have a jetronic connector and EV6 come with an uscar connector.

http://www.fordracingparts.com/download/charts/Fuel_Injectors_and_Adaptors.pdf

FUEL INJECTORS

First and foremost, adding larger fuel injectors alone will NOT create extra horsepower! The purchase of larger fuel

injectors should only be considered when your engine has exceeded the horsepower capacity of the existing fuel

injectors, at which point larger injectors are then required to SUPPORT the additional horsepower. If you add largerthan-

stock injectors to an otherwise stock engine, you should not expect any horsepower increase whatsoever.

First and foremost, adding larger fuel injectors alone will NOT create extra horsepower! The purchase of larger fuel

injectors should only be considered when your engine has exceeded the horsepower capacity of the existing fuel

injectors, at which point larger injectors are then required to SUPPORT the additional horsepower. If you add largerthan-

stock injectors to an otherwise stock engine, you should not expect any horsepower increase whatsoever.

The nominal injection pressure for most Ford EFI systems is 39.15 psi (270 kPa) “across the injector.” The term “across the injector” takes manifold pressure

and fuel rail pressure into account, and is usually referred to as “delta pressure.” (See “Measuring Fuel Pressure” below for more details.) Ford Racing’s fuel

injectors are always rated at 39.15 psi delta, so the fuel injector sizing discussions found below will assume a fuel pressure of at least 39.15 psi delta.and fuel rail pressure into account, and is usually referred to as “delta pressure.” (See “Measuring Fuel Pressure” below for more details.) Ford Racing’s fuel

There are some exceptions to the above-mentioned nominal injection pressure. In relatively recent years, emissions regulations have become so stringent that

the government is now regulating the emissions output that gasoline vehicles are allowed to produce even when the engine is not running! This is referred

to as “evaporative emissions” and results from unburned hydrocarbons (raw fuel) emitting into the atmosphere from the fuel tank, fuel lines, injector leakage,

intake manifold, etc. when the engine is shut off. This is the fundamental purpose of the charcoal canister (and hydrocarbon trap in the air-box on many

vehicles) and is also the reason that Ford switched to the Returnless Fuel Systems (RFS) found in production vehicles today. These systems have only a fuel

supply line from the tank to the engine, with no return line. The primary reason for these systems is that evaporative emissions increase as the temperature

of the fuel in the tank increases. On a conventional return system, the fuel is sent to the engine through the supply line, and the excess is returned (via the

mechanical fuel pressure regulator) to the tank through the return line. Since the engine is hot, this process heats up the fuel and thus increases evaporative

emissions. To combat this, the returnless fuel systems were invented. Currently, Ford uses 2 primary types of RFS which are called Electronic Returnless Fuel

System (ERFS) and Mechanical Returnless Fuel System (MRFS). The latter is the simpler of the two systems and controls the fuel rail to a constant pressure

via a regulator in the tank, which is typically set to around 60 psi. The powertrain control module (PCM) then calculates the pressure across the injector either

by inferring or measuring manifold pressure and subtracting from what it knows is the rail pressure set-point. ERFS, on the other hand, has no mechanical

regulator at all, but instead has a Fuel Rail Pressure Transducer (FRPT) mounted on the fuel rail that measures fuel rail pressure relative to manifold pressure

and feeds that information back to the PCM. The PCM then controls the Fuel Pump Driver Module (FPDM) which in turn varies the voltage to the fuel pump

(or pumps) in the tank to supply the correct pressure and flow rate to the injectors. Most of the time this pressure is maintained at 39.15 psi delta, but when

the fuel temperature rises, this pressure can be boosted in order to delay the onset of boiling the fuel. Some vehicles also boost the pressure under some

conditions in order to get away with using smaller flow-rate fuel injectors for various reasons beyond the scope of this tutorial. Both V6 and V8 Mustangs have

used ERFS since the 1999 model year and continue to do so today. The purpose of going into all this detail is to convey the message that if you choose your

fuel injectors based on a pressure of 39.15 psi delta (which is the pressure at which Ford Racing specifies the flow rate), the injectors will be correctly sized

regardless of which fuel system you actually have, and also to show you that fuel pressure on ERFS vehicles can change based on a number of conditions.

the government is now regulating the emissions output that gasoline vehicles are allowed to produce even when the engine is not running! This is referred

to as “evaporative emissions” and results from unburned hydrocarbons (raw fuel) emitting into the atmosphere from the fuel tank, fuel lines, injector leakage,

intake manifold, etc. when the engine is shut off. This is the fundamental purpose of the charcoal canister (and hydrocarbon trap in the air-box on many

vehicles) and is also the reason that Ford switched to the Returnless Fuel Systems (RFS) found in production vehicles today. These systems have only a fuel

supply line from the tank to the engine, with no return line. The primary reason for these systems is that evaporative emissions increase as the temperature

of the fuel in the tank increases. On a conventional return system, the fuel is sent to the engine through the supply line, and the excess is returned (via the

mechanical fuel pressure regulator) to the tank through the return line. Since the engine is hot, this process heats up the fuel and thus increases evaporative

emissions. To combat this, the returnless fuel systems were invented. Currently, Ford uses 2 primary types of RFS which are called Electronic Returnless Fuel

System (ERFS) and Mechanical Returnless Fuel System (MRFS). The latter is the simpler of the two systems and controls the fuel rail to a constant pressure

via a regulator in the tank, which is typically set to around 60 psi. The powertrain control module (PCM) then calculates the pressure across the injector either

by inferring or measuring manifold pressure and subtracting from what it knows is the rail pressure set-point. ERFS, on the other hand, has no mechanical

regulator at all, but instead has a Fuel Rail Pressure Transducer (FRPT) mounted on the fuel rail that measures fuel rail pressure relative to manifold pressure

and feeds that information back to the PCM. The PCM then controls the Fuel Pump Driver Module (FPDM) which in turn varies the voltage to the fuel pump

(or pumps) in the tank to supply the correct pressure and flow rate to the injectors. Most of the time this pressure is maintained at 39.15 psi delta, but when

the fuel temperature rises, this pressure can be boosted in order to delay the onset of boiling the fuel. Some vehicles also boost the pressure under some

conditions in order to get away with using smaller flow-rate fuel injectors for various reasons beyond the scope of this tutorial. Both V6 and V8 Mustangs have

used ERFS since the 1999 model year and continue to do so today. The purpose of going into all this detail is to convey the message that if you choose your

fuel injectors based on a pressure of 39.15 psi delta (which is the pressure at which Ford Racing specifies the flow rate), the injectors will be correctly sized

regardless of which fuel system you actually have, and also to show you that fuel pressure on ERFS vehicles can change based on a number of conditions.

You can use the following information to properly determine what size injectors are needed for various applications. For this example, we will use a naturally aspirated 5.0L V8 engine making 300 hp. Keep in mind that this is FLYWHEEL (also known as brake) horsepower, NOT wheel horsepower.

Engines require a certain fuel flow rate that is generally measured in lb/hr (pounds per hour) and can be calculated via knowledge of their Brake Specific Fuel

Consumption (BSFC). By definition, BSFC represents how much fuel (in lb) is required per hour per each brake horsepower the engine produces. Most naturally

aspirated production gasoline engines generally operate on a 0.42 to 0.52 lb/hp-hr BSFC at wide open throttle (WOT). High-performance gasoline and race

engines (12.5:1 compression ratio and higher) which tend to be extremely efficient can sometimes have a BSFC as low as 0.38 to 0.42. More clearly stated, this means that if you have a gasoline engine that makes 300 brake horsepower, its total maximum fuel requirement in lb/hr can be calculated as follows:

Fuel flow requirement = (brake horsepower) x (BSFC)

Example:

A 300 hp naturally aspirated gasoline-powered V8 requires what size fuel injector?

A 300 hp naturally aspirated gasoline-powered V8 requires what size fuel injector?

First, assume a BSFC of 0.50 lb/hr and injection pressure of 39.15 psi across the injector.

300 hp x 0.50 lb/hp-hr = 150 lb/hr maximum total fuel flow requirement

Since this is the total fuel flow requirement to the engine, we must now divide this by the number of injectors being used to determine the flow rate necessary

for each injector so that you can select the correct size injector from this catalog. In this example, we have an 8-cylinder engine using 1 injector per cylinder,

which gives:

150 lb/hr/8 injectors = 18.8 lb/hr per cylinder

So, technically, the engine only needs a 19 lb/hr fuel injector to support 300 hp, but this will require that the injector is at nearly a 100% duty cycle in order to achieve this horsepower level. Duty cycle refers to how long the injector needs to be open (flowing fuel) in order to supply the required amount of fuel. If the injector needs a 100% duty cycle at a particular engine speed and load to inject enough fuel, that means it is open all the time. Under most conditions, fuel is injected when the intake valves are closed, which helps with fuel atomization and efficiency. If the injectors need to be on 100% of the time to supply enough fuel, this means that some fuel is being injected while the intake valves are open. Depending on the overlap of the cam in the engine, some of this unburned fuel can be blown right past the exhaust valve, or be poorly atomized, which makes for a less efficient combustion process. Perhaps more importantly, operating a fuel injector between roughly 85% and 99% duty cycle does not give the injector sufficient time to close before it is commanded to open again.

This can cause extreme variability in the amount of fuel actually injected, which can sometimes result in a rich condition. Similar issues exist at the low end of the flow region at extremely low duty cycles, but this is highly dependent on the type and flow rate of each model of injector. In this case the injector does not have enough time to fully open before it is commanded to close again, which causes extreme variability that can result in a lean condition. For these reasons, we generally recommended selecting an injector with a flow rate sufficiently high that it will not be required to exceed an 85% duty cycle. So to figure out what size fuel injector will result in an 85% duty cycle, divide the original result by 0.85:

18.75 lb/hr/0.85 = 22 .1 lb/hr requirement.

Here is an online calculator that can help you determine the right size injector for your setup.

http://www.witchhunter.com/injectorcalc1.php4

Last edited: