Digital_Synapse

forum member

Found some good reading on another forum, cost the guy alot of time and money to do this test. I figured with all the new header designs around and people on the fence about getting them...this would squash some rumors and myths about loss of power, etc. Here ya go.

And this too...

These guys are running 600+hp and not gaining more than 8hp at peak RPM on the 1 7/8", and 800+hp drap applications are barely calling for the larger of the 2. Just some food for thought.

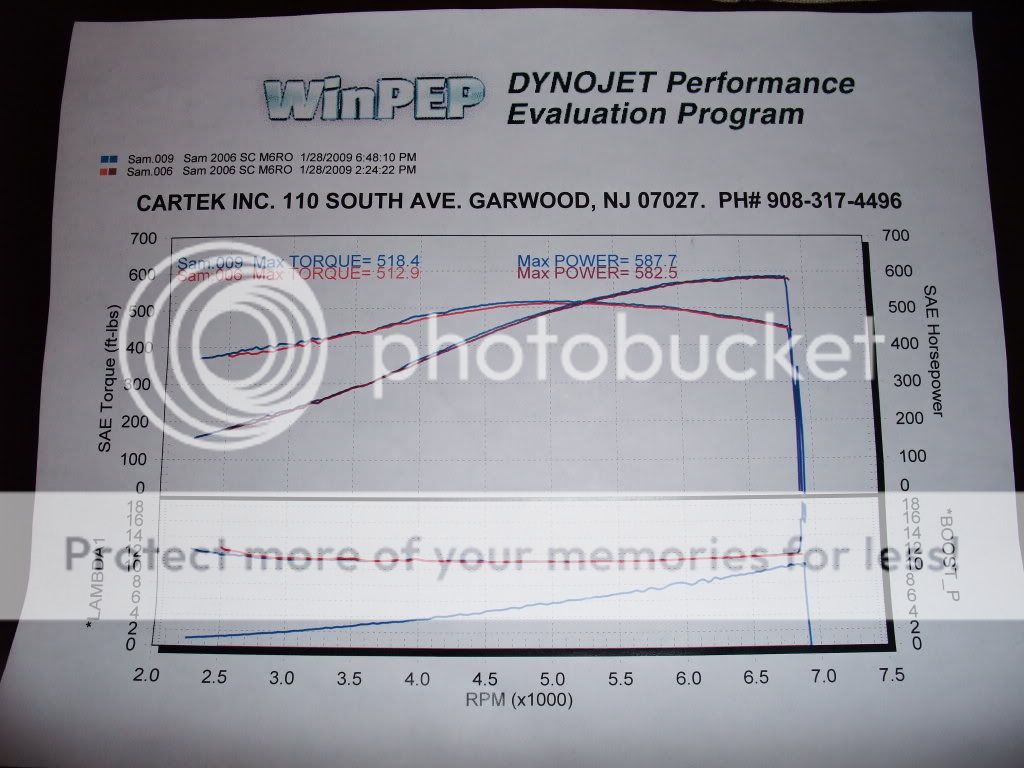

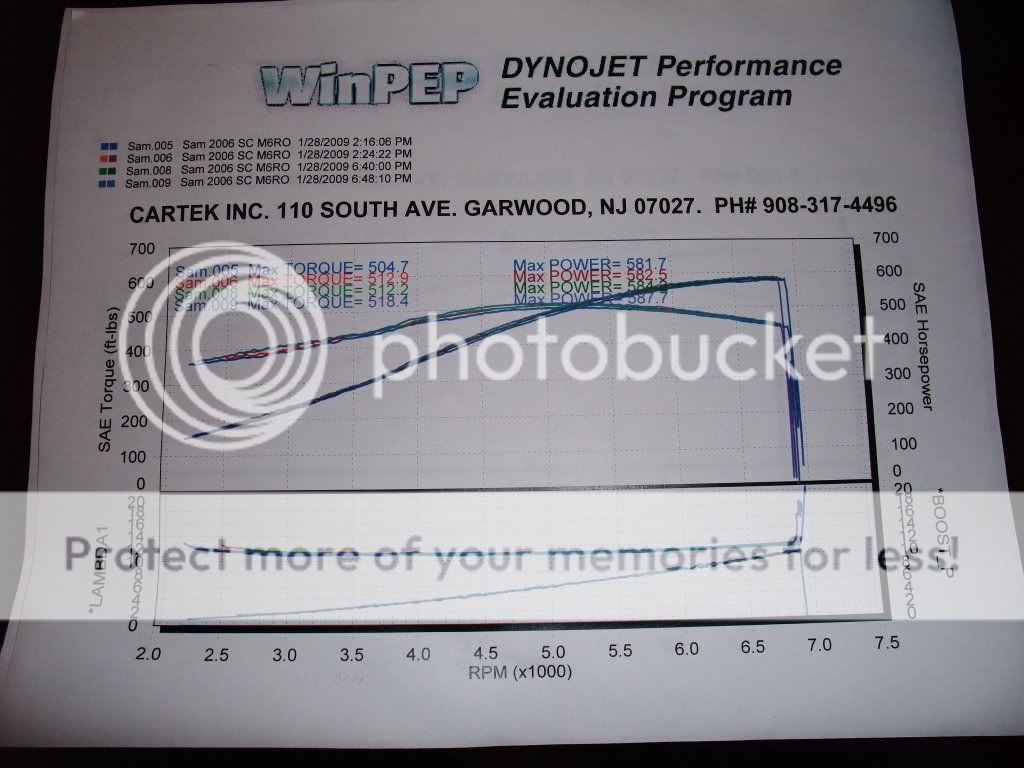

PowerLabs said:The purpose of this test was to find out how much, if any, power stands to be gained by increasing the header primary size from 1 3/4" to 1 7/8" in a supercharged car. The general consensus on the forum has been that the larger diameter primaries will produce more top end, at the cost of some low end torque gains.

What really interested me were some claims that very large amounts of power was being held back by the 1 3/4" headers, because their primaries were "restrictive". I decided to investigate:

So here it is: we baselined my car, a 2006 Corvette C6 Z-51 with a ported TB and Intake manifold, an A&A V2 Si-Trim Vortech Supercharger running a 3.8" Pulley, and Kooks 1 3/4" Headers with a 3" catted X-pipe and Z06 Exhausts.

Then we swapped the headers for 1 7/8" American Racing headers with a 3" catted X- pipe keeping the same Z06 Exhaust.

Same Car

Same Fuel

Same Dyno

Same Correction Factors

Same Smoothing

Same Atmospheric Conditions

Same temperatures

Same day

4 hours apart.

The results, before re-tuning for the headers, are as close to a real back to back comparison as you can get. There was:

No change in the boost level whatsoever,

A leaning in the Air/Fuel Ratio of about 0.1points.

Julio then attempted to add timing, as per my request, in an attempt to make more power from the 1 7/8" headers. Adding time anywhere caused the ECU to pull it back out: this is really as much power as the car can make.

The car was tuned before hand to make as much power as we could safely get from the setup with the 1 3/4" headers. It is now tuned the same way for the 1 7/8" headers.

The before and after dyno charts are posted below.

My thoughts:

1- The boost does not change *AT ALL*. It looks like a solid line but in fact it consists of two lines perfectly over each other. This means that swapping the headers did not reduce exhaust backpressure in any way shape or form. That is why little power was gained.

2- I expected a loss of low end torque from the swap, but I was wrong: the 1 7/8" headers gave up nothing over the 1 3/4" ones. This is very nice :thumbs:

Here are all the relevant dynos. 001 through 005 were for injector resizing. 006 is the best tune with 1 3/4" headers. 07 is the 1 7/8" header dyno and 08 is the 1 7/8" dyno with a tune. Boost and AFR below.

Conclusion: The 1 7/8" headers gave up *nothing* in the low end, in fact gaining a small amount of torque, while maing slightly more power. If you aready have 1 3/4" headers, and are making similar numbers, spending the money to "upgrade" to 1 7/8" is not a good investment given the minimal gains

If you have a F/I car, or are thinking of going to F/I, there is no reason not to get 1 7/8" headers, given the extra power with no trade-offs

If you have a F/I car making a LOT more power than me, you stand to gain a LOT more from the header swap, since smaller primaries will always "max out" sooner. That said, 600WHP does not appear to be the point where they max out.

Finally, it is now clear to me that the headers are NOT a restriction to how much power a basic supercharged car makes. The 10PSI boost is a considerable number given the power made; a MUCH better place to remove airflow restriction and lower that number while making more power would be the camshaft; I believe a good cam could make 50HP or more at 2PSI or less boost. Perhaps this can be my next mod?

And last but not least... Guys, it cost me over $2000 to do this back to back comparison just for the sake of knowledge. Please be nice and don't get my tread locked?

Thank you!

And this too...

I looked and looked on many mustang forums, and couldn't find anything even close to this. Look past the Vette and T/A talk, 1 3/4" is 1 3/4" no matter what it's bolted up to.Jason 98 TA said:After 5 days of engine dyno testing different combinations & packages I'm proud to announce I finally have some extra time to provide you guys with some of the information we've learned!

The very first dyno testing we did compared header primaries & power output from 3000 to 6000rpm. The base engine was completely stock 01 engine with only a Fast intake installed. We dyno tested both the Pacesetter 1 3/4" coated long tubes & the TSP 1 7/8" long tube headers. The goal was to see how the larger primaries would effect power on a basically stock engine. To my suprise the 1 7/8" headers made a considerable amount more power than the 1 3/4" headers! Power output was virtually identical untiL 4800 rpm when the 1 7/8" headers began to outpower the smaller 1 3/4" primaries. The 1 7/8" headers made a peak hp of 414.x hp & 421lb ft while the 1 3/4" headers made 408hp & 419 lb ft of torque. While this isn't a huge difference, it definately shows that even on a basically stock car the larger headers are still a good investment! Power under the 4800rpm point was virtually identical! Infact the 3000 rpm numbers were 209hp 366 tq from the 1 3/4" headers & 209hp 359.9 tq!

Both dyno runs were backed up several times & the combos used very similar air fuels & locked in timing at 28 degrees. I thought this was a pretty cool comparision, because the common thought is the 1 7/8" headers is just overkill on anything smaller than stroker setups. This is apparently not the case....

Here's a few pics of the 1 7/8" headers installed on the engine dyno

The dyno video can be seen at:

http://www.precisionracecomponents.com/178dyno.mpg

I'll have some of the guys help me bust out some detailed dyno graphs for you guys to checkout in the morning.

Enjoy!!

I would like to offer anyone who doesn't agree with these finding to come down to our shop & I will be more than happy to redo any testing we've done over the last 5 days. All our engine dyno testing was done at a independent dyno facility & as long as your willing to pay the dyno testing fees, I'll glady reproduce any testing we've done. This is a very reasonable offer, if you don't want to put your money where your mouth is then please don't jump in this thread & talk crap. I'll gladly defend any testing we've done, I'm always looking for a opportunity to get back to the engine dyno for more testing.

These guys are running 600+hp and not gaining more than 8hp at peak RPM on the 1 7/8", and 800+hp drap applications are barely calling for the larger of the 2. Just some food for thought.