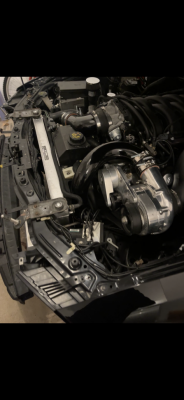

I FINALLY finished my engine rebuild project that started last January. Initially, things started out OK, but then turned into a comedy of errors.

It took about 4 months to find a shop that A, I trusted, B, wasn’t ridiculously expensive, C, could do the job without a 6 month wait, D, could get parts.

I also had to find someone to remove and reinstall the engine because my health no longer allows that level of work.

I found a machine shop/builder with a good reputation who had just moved into a larger shop. As luck would have it, the shop that installed my torque converter a couple of years ago relocated in the same industrial park as the builder and would do the removal. It took about a month to get parts and rebuild the engine with forged rods and pistons. I was there when the engine was started for the first time and the timing cover had an oil leak. That was fixed in 3 days. I get the car back and start to break in the engine. About a week later, the drivers side valve cover is leaking oil. I try to see if a bolt was missed when tightening, and discover that all the valve cover bolts are over tightened. A new kid the builder had hired did not check specs when doing reassembly after timing cover fix.

I drive the car around for a couple of weeks breaking in engine, and it drives perfectly. I go to do datalog to send to Lito, and it won’t shift from 3rd to 4th gear or rev past 5K RPMs. Lito says everything looks good on the datalog and doesn’t know what’s happening.

After a couple of weeks of trouble shooting, I find the nut on the alternator that holds positive cable is loose. See kid from before. Everything works at low rpm, but vibrations at WOT causes misfires. Tighten nut and car runs good. Send Lito datalog.

He says to check for loose exhaust because knock sensors are going crazy. I cannot find anything loose on car, so he tunes as is. Unfortunately, at this point, it’s August and Lito is on vacation and it takes a week for him to respond to an email. After a month we get it tuned. I take it to a couple of HPDE track days and the drag strip and it runs very good. I decide to install smaller pulley on SC and check knock sensors while I’m at it. Turns out the shop that reinstalled the engine, had torqued the KSs to 25 ft/lbs instead of the required 15 ft/lbs. This was causing the false knock Lito was seeing. I replaced the KSs and put everything back together. I installed the last tune, did a final datalog, and as of yesterday, all is good. FINALLY.

It took about 4 months to find a shop that A, I trusted, B, wasn’t ridiculously expensive, C, could do the job without a 6 month wait, D, could get parts.

I also had to find someone to remove and reinstall the engine because my health no longer allows that level of work.

I found a machine shop/builder with a good reputation who had just moved into a larger shop. As luck would have it, the shop that installed my torque converter a couple of years ago relocated in the same industrial park as the builder and would do the removal. It took about a month to get parts and rebuild the engine with forged rods and pistons. I was there when the engine was started for the first time and the timing cover had an oil leak. That was fixed in 3 days. I get the car back and start to break in the engine. About a week later, the drivers side valve cover is leaking oil. I try to see if a bolt was missed when tightening, and discover that all the valve cover bolts are over tightened. A new kid the builder had hired did not check specs when doing reassembly after timing cover fix.

I drive the car around for a couple of weeks breaking in engine, and it drives perfectly. I go to do datalog to send to Lito, and it won’t shift from 3rd to 4th gear or rev past 5K RPMs. Lito says everything looks good on the datalog and doesn’t know what’s happening.

After a couple of weeks of trouble shooting, I find the nut on the alternator that holds positive cable is loose. See kid from before. Everything works at low rpm, but vibrations at WOT causes misfires. Tighten nut and car runs good. Send Lito datalog.

He says to check for loose exhaust because knock sensors are going crazy. I cannot find anything loose on car, so he tunes as is. Unfortunately, at this point, it’s August and Lito is on vacation and it takes a week for him to respond to an email. After a month we get it tuned. I take it to a couple of HPDE track days and the drag strip and it runs very good. I decide to install smaller pulley on SC and check knock sensors while I’m at it. Turns out the shop that reinstalled the engine, had torqued the KSs to 25 ft/lbs instead of the required 15 ft/lbs. This was causing the false knock Lito was seeing. I replaced the KSs and put everything back together. I installed the last tune, did a final datalog, and as of yesterday, all is good. FINALLY.